An intelligent coal discharge method based on real-time monitoring of top-coal thickness variation

A technology of thickness change and real-time monitoring, applied in the field of coal caving in the fully mechanized caving face, based on the real-time monitoring of top coal thickness variation in the field of intelligent coal caving, which can solve over-discharging or under-discharging, coal quality decline, resource loss, etc. problems, to achieve remarkable results, strong adaptability, and accurate control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

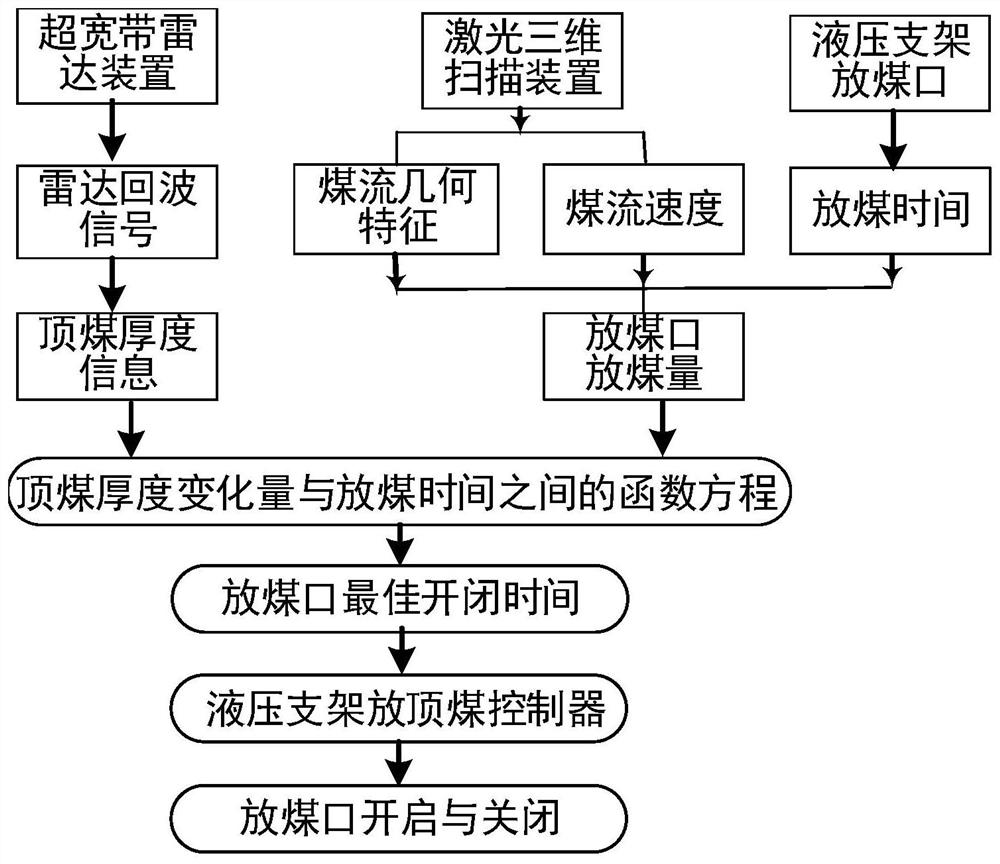

[0026] Such as figure 1 As shown, the intelligent coal discharge method based on the real-time monitoring of top-coal thickness variation of the present invention utilizes the ultra-wideband radar device 4 and the laser three-dimensional scanning device 6 to monitor the top-coal thickness information in real time, and automatically adjusts the coal discharge according to the top-coal thickness variation Mouth opening and closing time, the specific steps include:

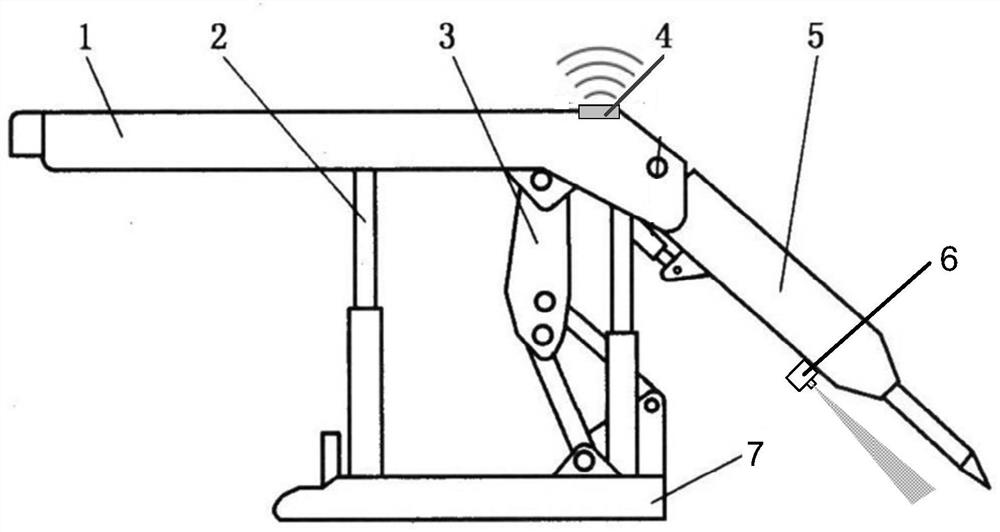

[0027] (1) The ultra-wideband radar device is installed on the top beam 1 of the hydraulic support near the middle and rear position, and the ultra-wideband radar device 4 includes a transmitting device, a receiving device and a control machine connected in sequence; the hydraulic support includes a top beam 1. Upright pole 2, cover beam 3, tail beam 5, base 7, controller and electro-hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com