Coal cutter cable automatic dragging control method based on double closed-loop control

A technology of double closed-loop control and drag control, which is applied in electric controllers, controllers with specific characteristics, and earth-moving drilling and mining, etc., can solve the problems of low control accuracy and broken cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

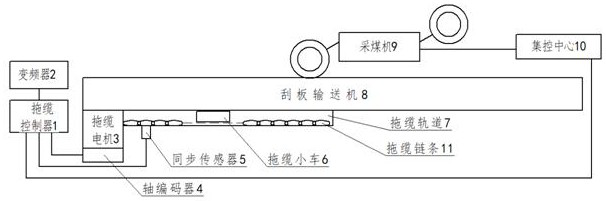

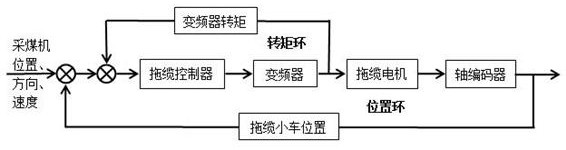

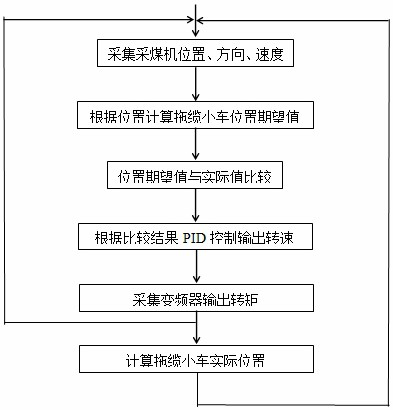

[0020] Such as figure 1 It can be seen that an automatic towing control method for a shearer cable based on double closed-loop control involves equipment including a towline controller 1, a towline frequency converter 2, a towline motor 3, a towline shaft encoder 4, and a synchronization sensor 5 , 6 towline trolleys, 7 towline running tracks, 8 scraper conveyors, 9 coal shearers, and 10 centralized control centers. The tow cable controller 1 calculates the position of the tow cable trolley 6 on the tow cable running track by collecting data from the shaft encoder 4 and the synchronous sensor 5, and controls the frequency converter and the tow trolley according to the actual position of the tow cable trolley 6 and the position of the shearer 9. The cable motor moves to realize the position loop to control the operation of the towing trolley; at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com