Method and apparatus for concentrated energy drilling, core drilling, automated mining and tunneling

a technology of concentrated energy and drilling method, applied in the field of drilling, core drilling, mining, etc., can solve the problems of the the diamond core drilling of rock used to explore, and the general slowest form of drilling, so as to reduce the damage of material, and reduce the energy required to drill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

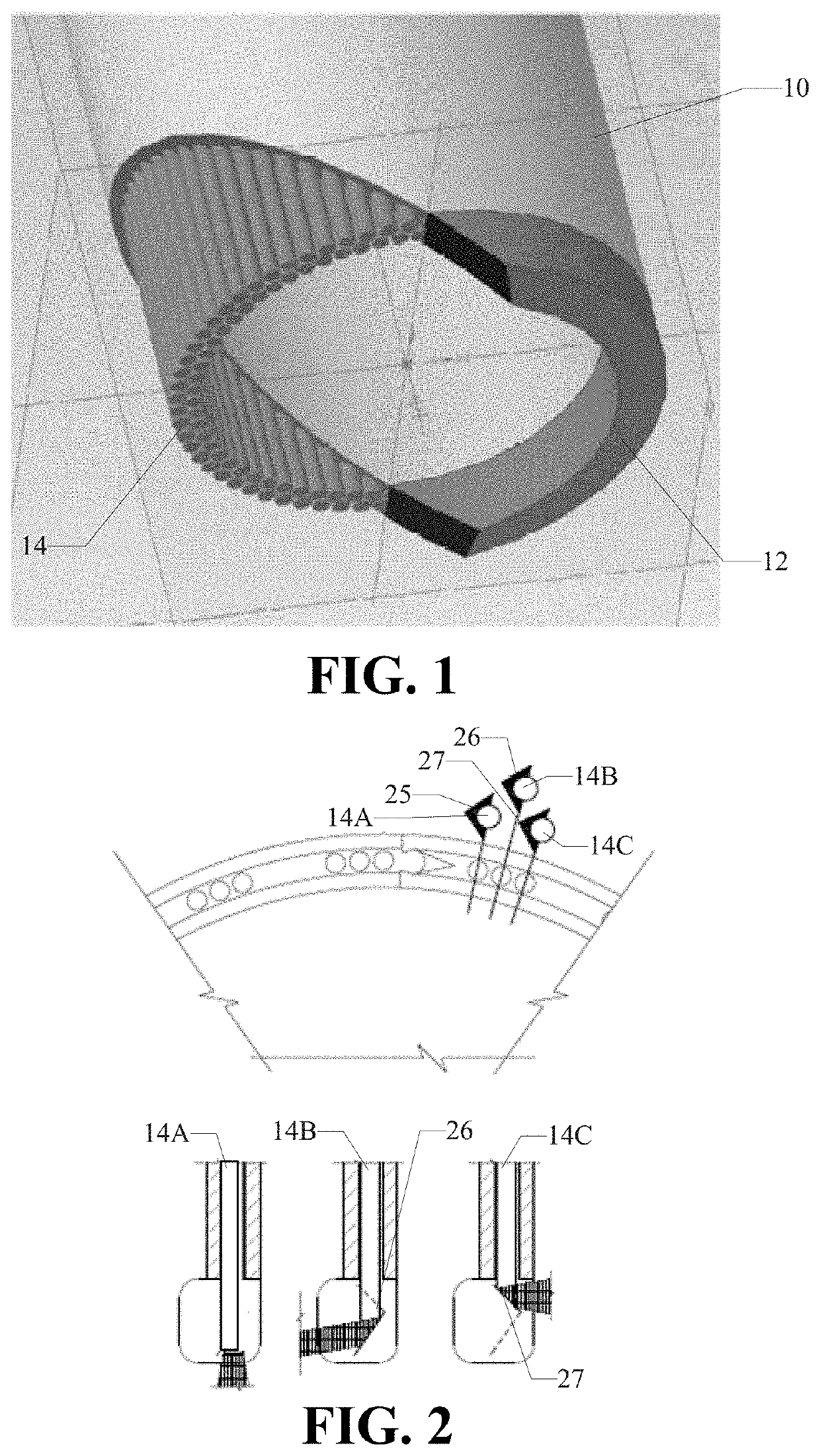

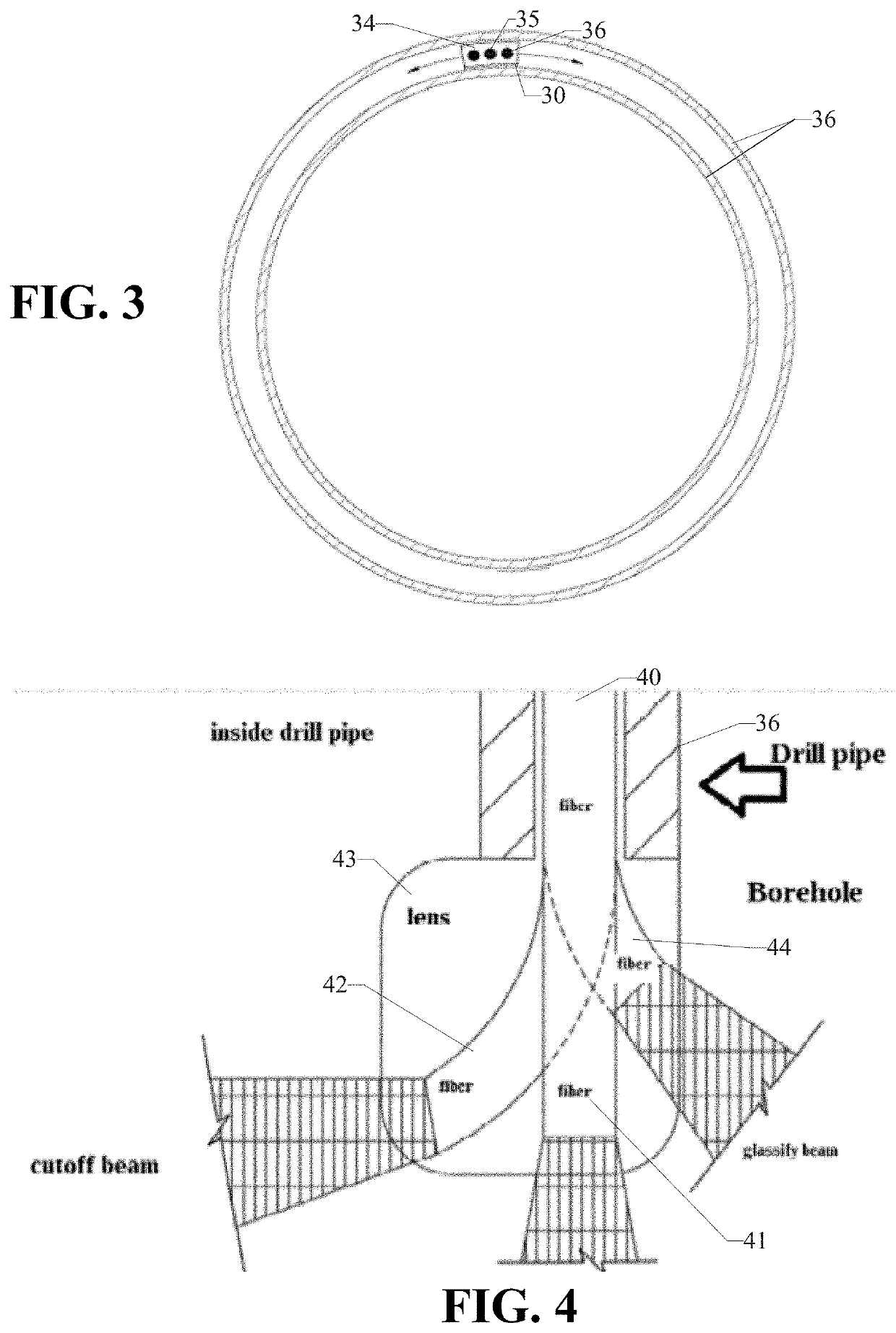

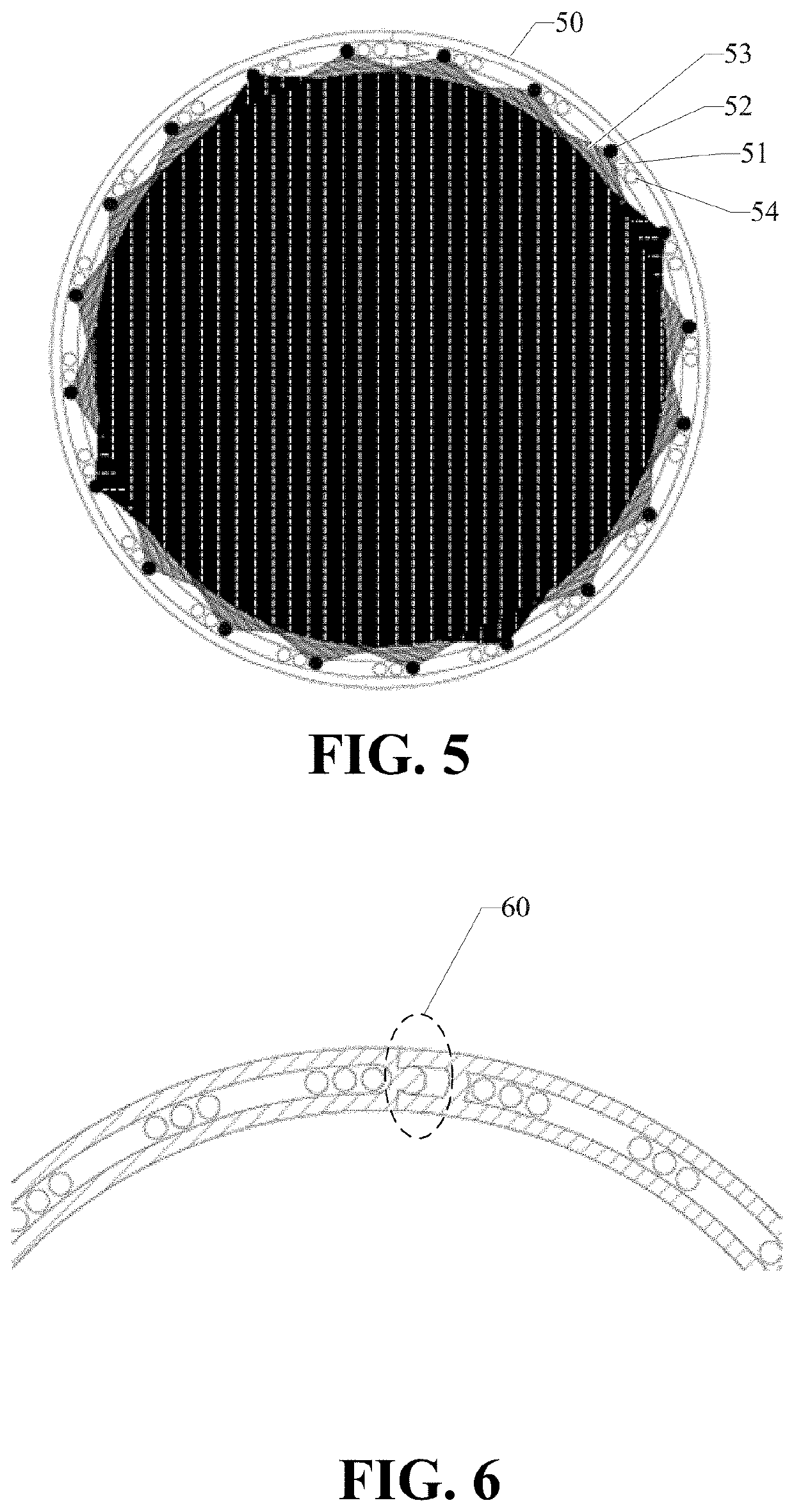

[0034]The claims define the matter for protection. Disclosed in the specification is an apparatus, system, and method with several embodiments that overcome the limitations of the prior art. The disclosure accomplishes this through a system that destroys only a tiny portion of the rock, concrete or other material to be drilled or tunneled through via concentrated beam energy on the periphery, similar to how a cookie cutter works. The system greatly reduces the energy required, increases the speed, and requires no rotational friction that slows progress greatly at depth, returns drill cores or mined / tunneled material intact and can even be done remotely without personnel underground. It can operate underwater and in poisonous gas areas and under lethal pressures. It can be applied to core drilling, conventional drilling such as oil / gas drilling, mining, tunneling and other drilling / boring activities such as metal or ceramic drilling. Research indicates it will be faster that current ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com