Steeply pitching seam mining method

A mining method and steeply inclined technology, applied in the field of steeply inclined coal seam mining, can solve the problems of high labor intensity, ventilation and unreliable and practical three-machine mining equipment mining technology, etc., to increase coal output, improve mining efficiency, and ensure safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0027] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

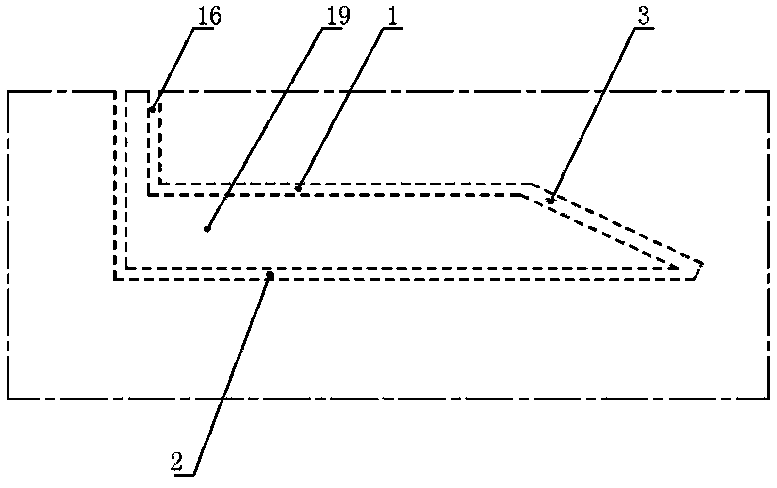

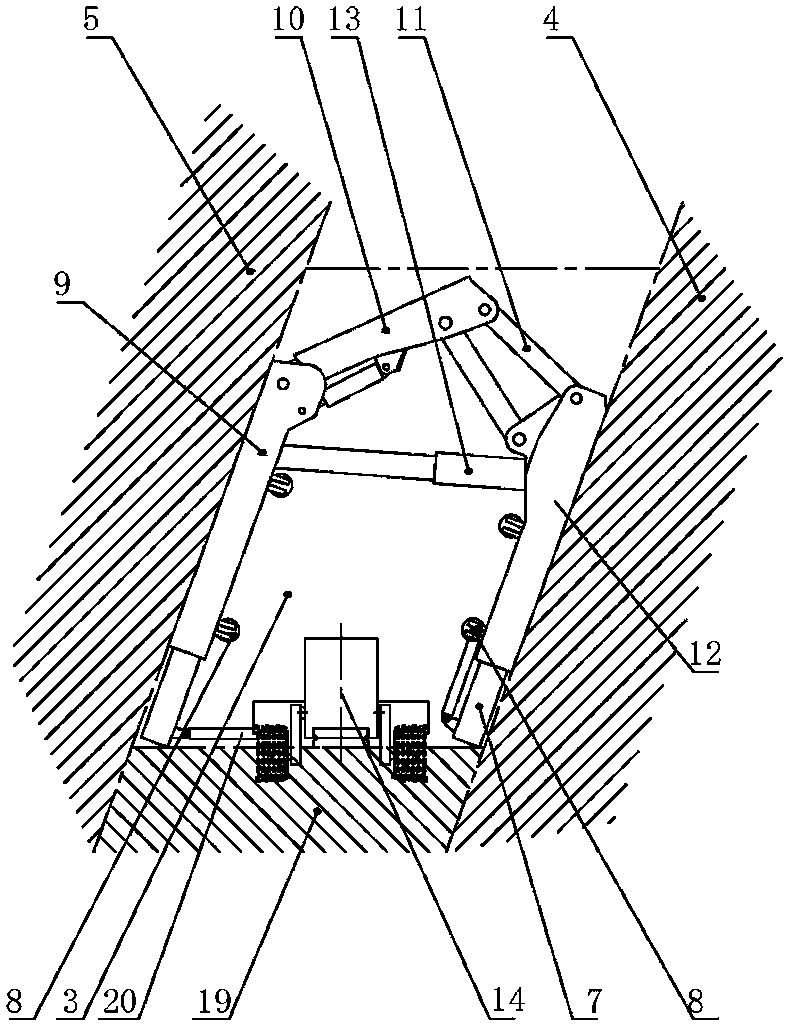

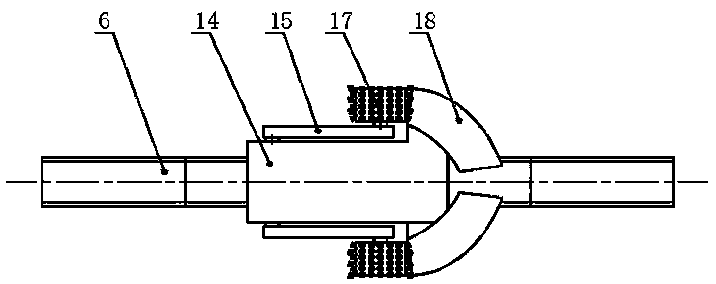

[0028] as attached figure 1 , 2 As shown, the steeply inclined coal seam mining method includes the following steps: Step 1, the steeply inclined coal seam is horizontally mined in sections, and a wind return trough 1 is arranged horizontally along the coal seam trend in the upper part of the section, and a wind return channel 1 is arranged horizontally along the coal seam trend in the lower part of the section Transport along the channel 2 to the boundary of the mining area; step 2, arrange the incision 3 obliquely along the coal seam (the incision 3 is the roadway of the working face), and the angle between the incision 3 and the transport channel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com