Linear vibration motor

A technology of linear vibration and vibration system, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of affecting the stability of vibration motor performance, easy to generate splashes, and difficult to fix the magnetic fluid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

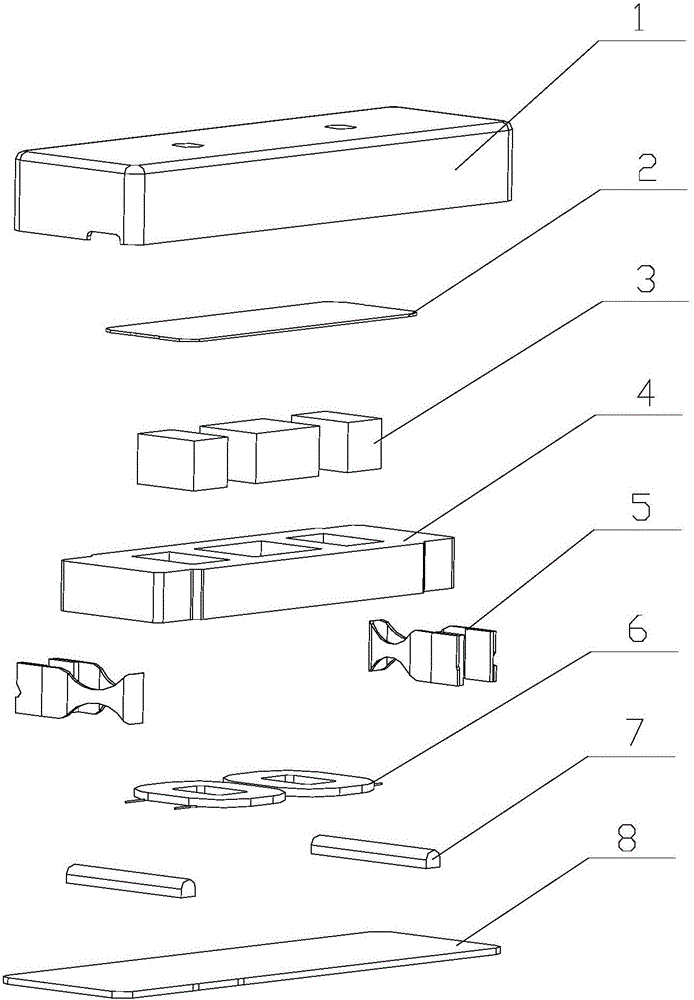

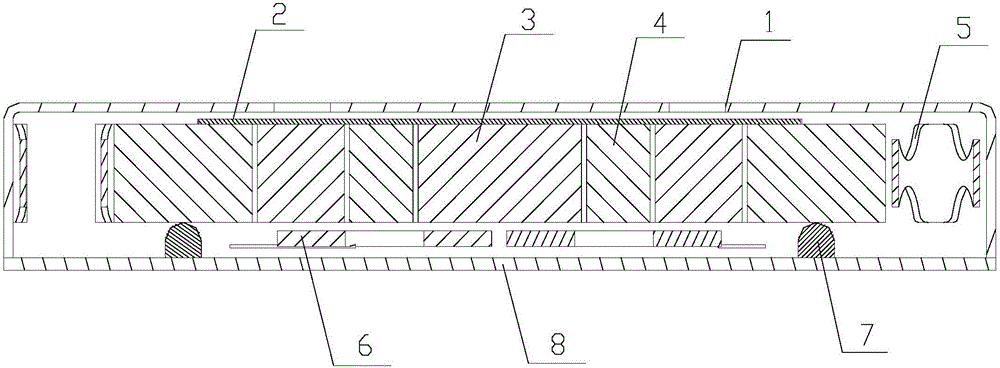

[0034] Embodiment 1 (the fixed part of the elastic support is fixedly connected with the lower shell, and the sliding part and the mass block slide and rub)

[0035] In the first embodiment, the shell includes an upper shell 1 provided with a notch, and a lower shell 8 which is fitly connected with the upper shell 1 and forms a cavity, and the vibration system and the stator are accommodated in the cavity. Wherein, the lower case 8 is made of a magnetically permeable material, and can generate a mutual attracting magnetic force with the permanent magnet 3 . The elastic support 7 is a strip-shaped structure, and two elastic supports 7 are symmetrically fixed on both sides of the stator and kept a certain distance therefrom, and the elastic support 7 is located on the same side of the mass block 4. The other side of the mass block 4 is provided with a magnetically permeable plate 2 , and the magnetically permeable plate 2 is pasted on the side of the mass block 4 by pasting or w...

Embodiment 2

[0038] Embodiment 2 (the fixed part of the elastic support is fixedly connected with the mass block, and the sliding part and the lower shell slide and rub)

[0039] In the second embodiment, the structures of the casing, the spring member, the magnetically conductive plate and the elastic support member can all refer to the description in the first embodiment, and will not be repeated here. In the second embodiment, the elastic support is located on the same side of the mass block, and the fixed part of the elastic support is fixedly connected with the mass block, and moves with the movement of the mass block, and the sliding part of the elastic support is in contact with the lower mass block. shell sliding contact.

[0040] Wherein, the two ends of the mass block are respectively elastically connected to the side wall of the upper case through the spring parts, and the elastic restoring force is provided for the movement of the mass block through the spring parts. During the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com