Flexible passive adaptation type fairing disc and flexible sandwich layer thereof and method for operating flexible passive adaptation type fairing discs

An adaptable and flexible technology, applied in the direction of wheels with flexible working parts, optical surface grinders, grinding/polishing equipment, etc., can solve problems such as low smoothing efficiency, high cost, and complex smoothing disk control , to achieve the effect of high smoothing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

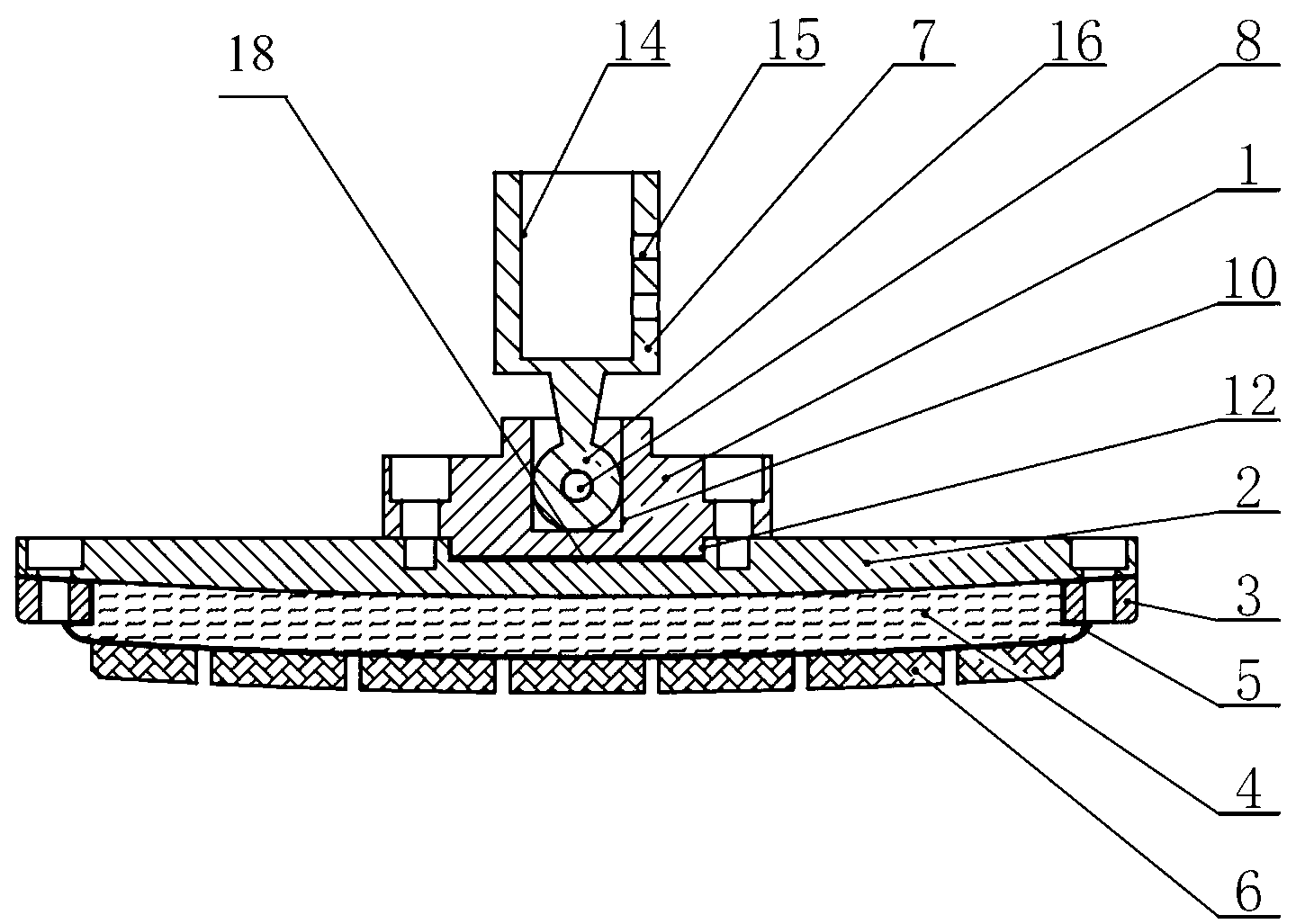

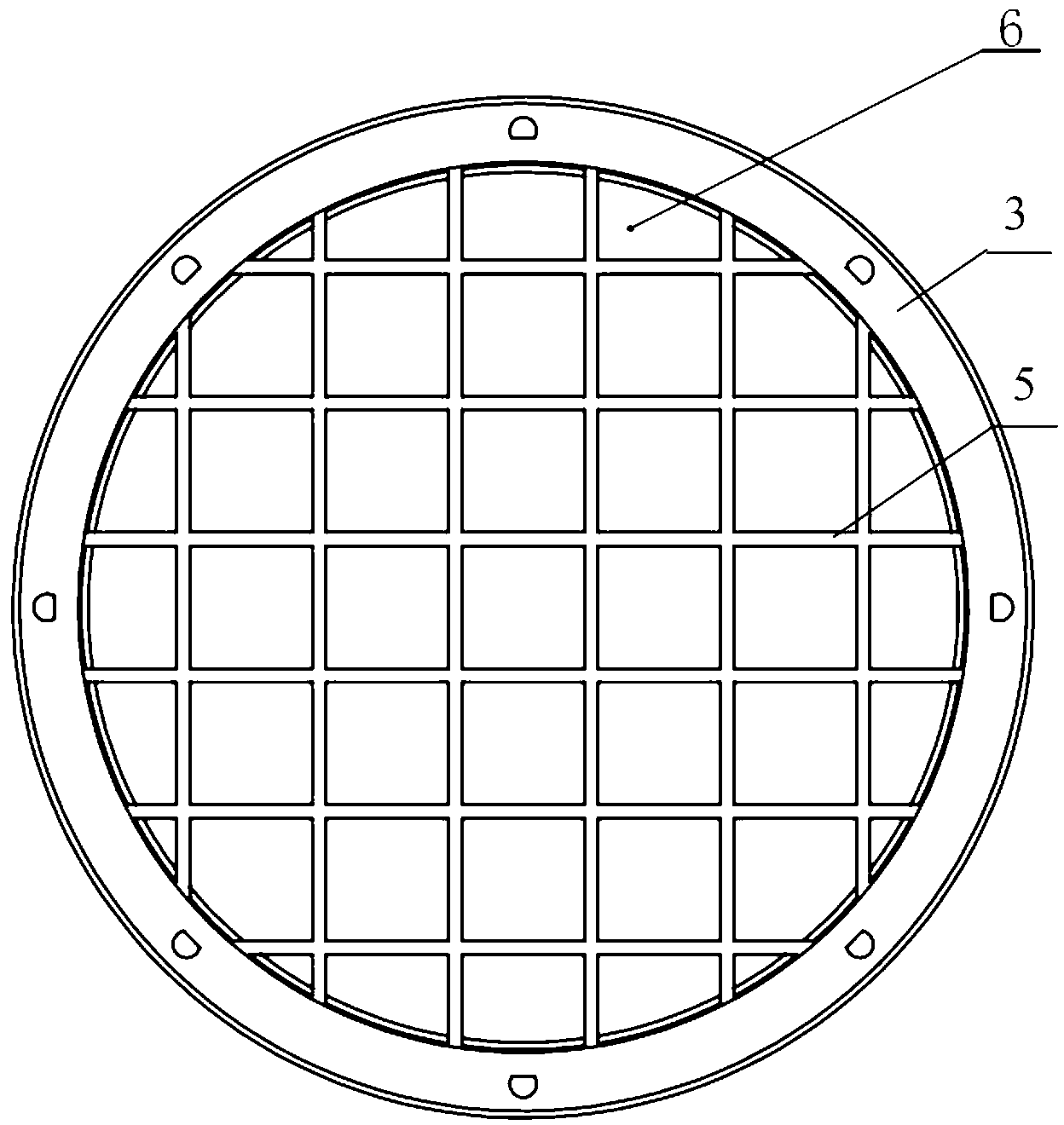

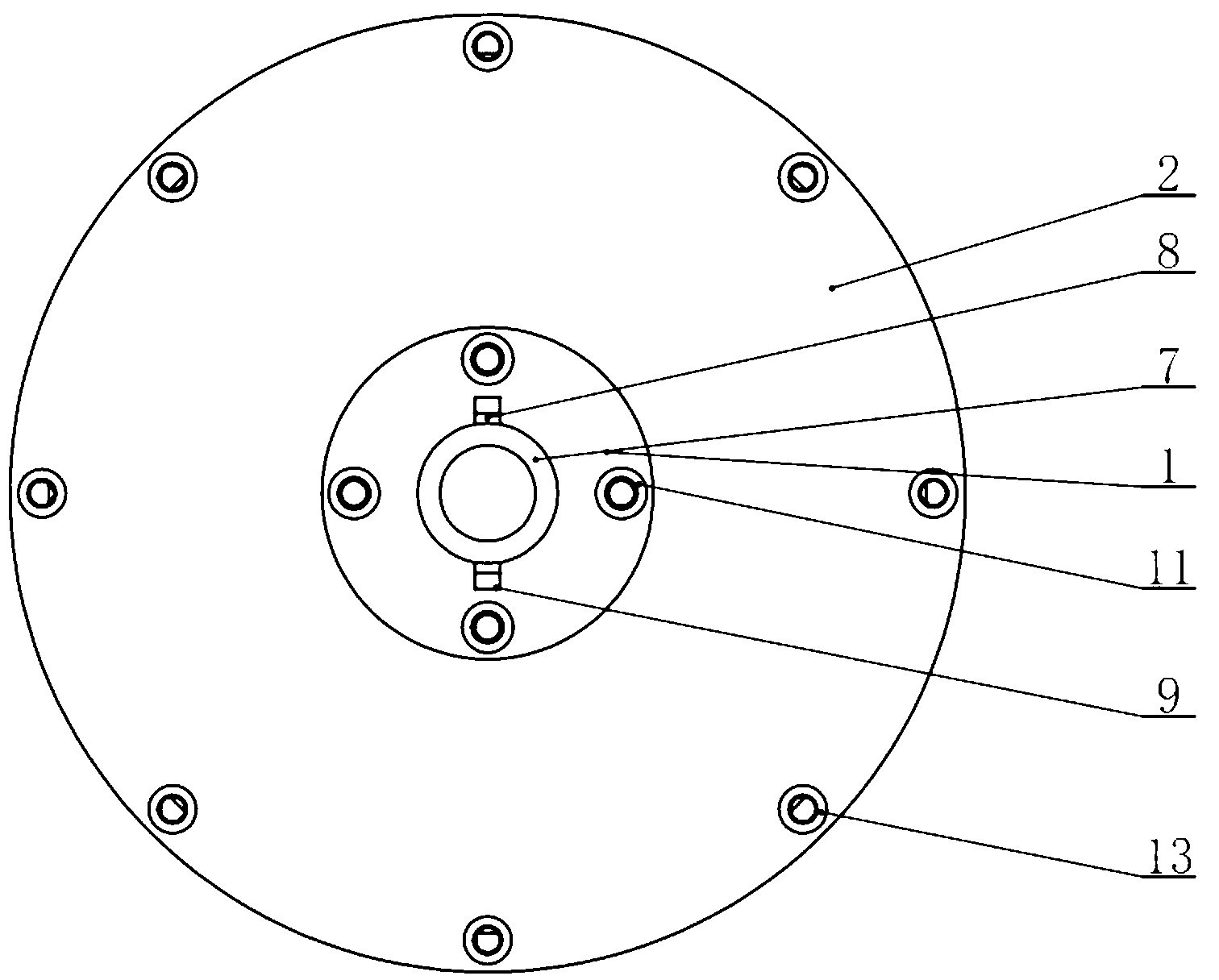

[0024] A kind of such as the present invention Figure 1 ~ Figure 3 The shown flexible passive adaptive smooth disc 18 includes a chassis 2 , a connecting flange 1 and a flexible interlayer 4 . The lower surface of the chassis 2 is spherical, and the radius of curvature of the spherical surface is the same as the nearest spherical radius of the aspheric mirror surface 17 to be processed. / 3; a connection flange 1 is connected above the chassis 2, and a plurality of threaded connection holes 11 are provided on the connection flange 1 through which countersunk screws pass, and the connection flange 1 is fixed on the upper surface of the chassis 2 by countersunk screws. The top of the connection flange 1 is movably connected with a ball shaft 7 that can be connected to the machine tool. The middle part of the upper surface of the connection flang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com