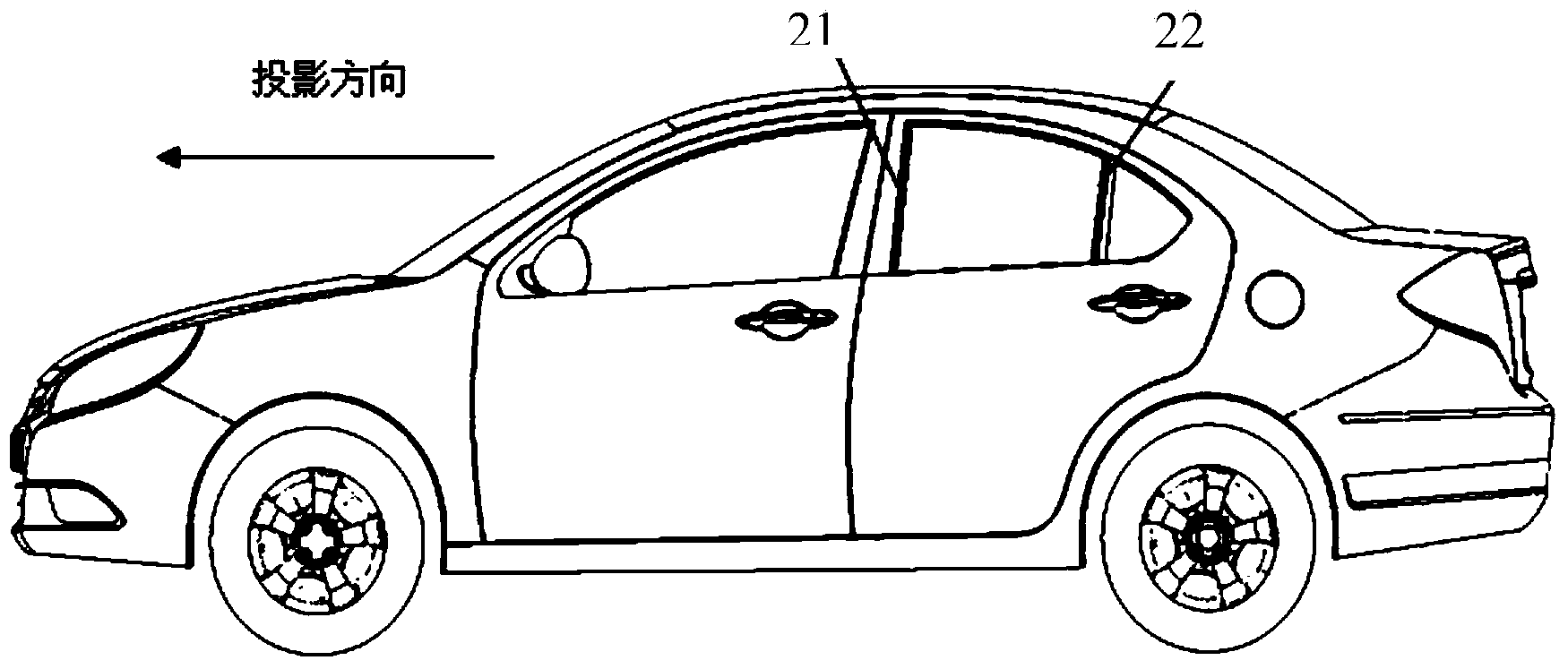

Manufacturing method for lifting guide rail of side window glass of automobile

A manufacturing method and technology for window glass, applied in the field of window guides and car bodies, can solve the problems that the guide rails cannot be well overlapped, time-consuming, uneven lifting, etc., so as to achieve a stable glass lifting process, strong operability, and accuracy. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solution of the present invention is described in detail below through the examples, and the following examples are only exemplary and can only be used to explain and illustrate the technical solution of the present invention, rather than being interpreted as a limitation to the technical solution of the present invention.

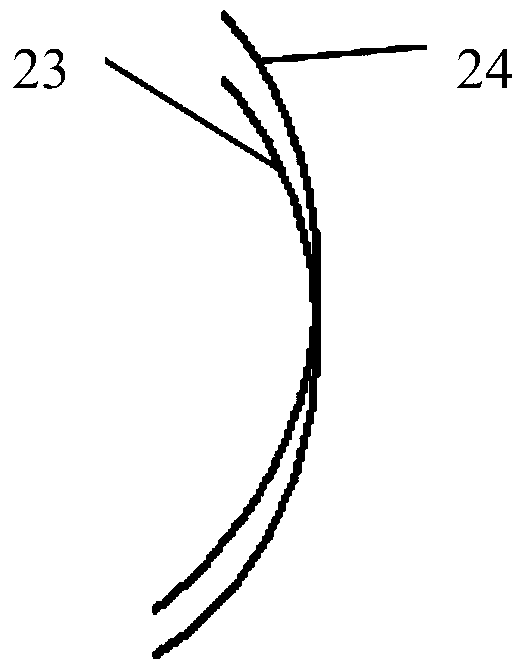

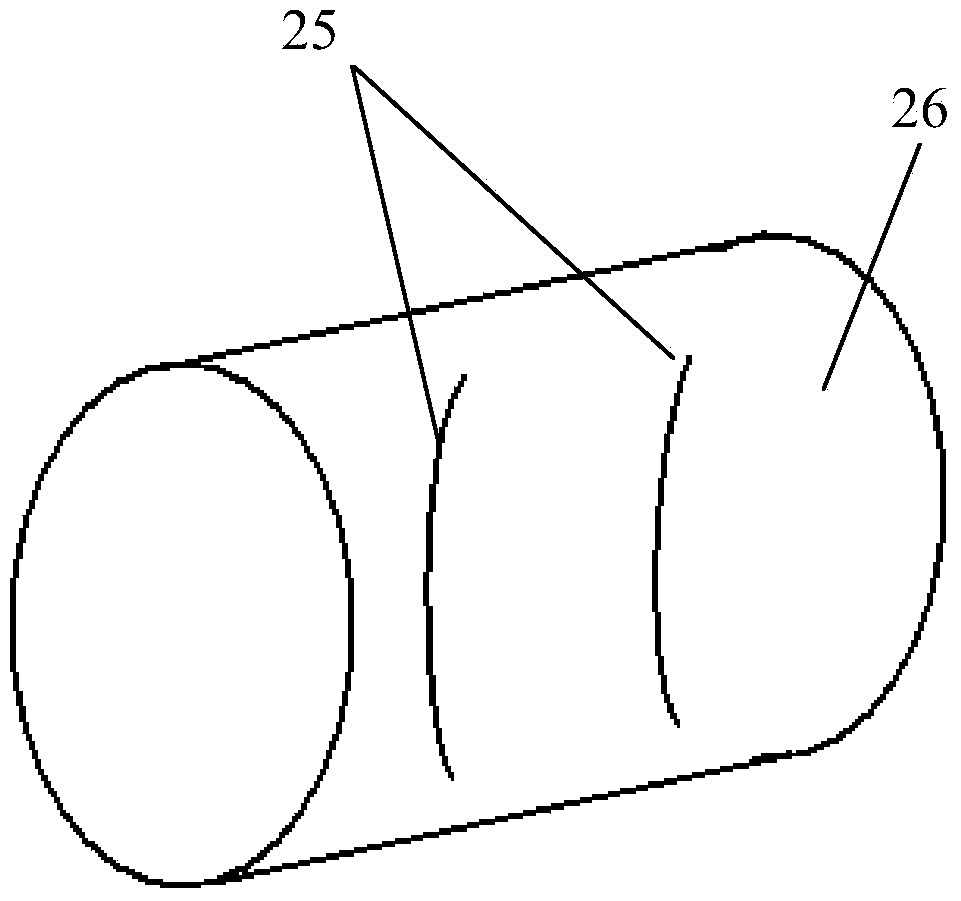

[0041] In the present invention, a single-curvature surface refers to a surface composed of only one curvature, such as a cylinder.

[0042] A double-curvature surface refers to a surface composed of two curvatures in a shape surface, such as a ring, a drum, or a ball.

[0043] Helix refers to threads on screws and bolts, which are unique to cylindrical surfaces.

[0044] The guide rail refers to the part that guides and limits the glass during the lifting process of the glass.

[0045] The wool groove refers to the waterproof and windproof rubber strip installed on the guide rail and matched with the glass.

[0046] The following ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com