Small-caliber straight pipe butt welding device

A butt welding and small-diameter technology, which is applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems affecting the quality of the weld seam and the restriction of the gas protection on the back of the assembly accuracy, so as to ensure the final forming, stable pressure, and The effect of mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below with reference to preferred specific embodiments in conjunction with the accompanying drawings. The features and advantages of the present invention will become clearer with these descriptions.

[0058] In the present invention, the main problem to be solved is, for small-diameter and thin-walled heat exchange tubes, under the condition of filling the melting ring, butt welding is accurately performed to ensure the shape and quality of the weld seam. For this reason, it is necessary to accurately position the heat exchange tube and the melting ring to be welded under the action of shielding gas, so as to achieve good welding.

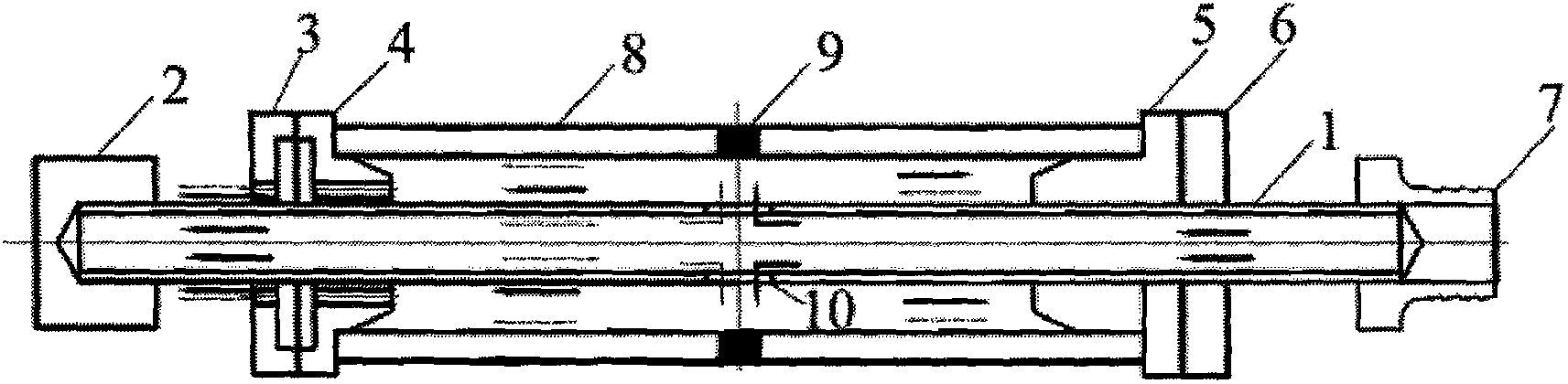

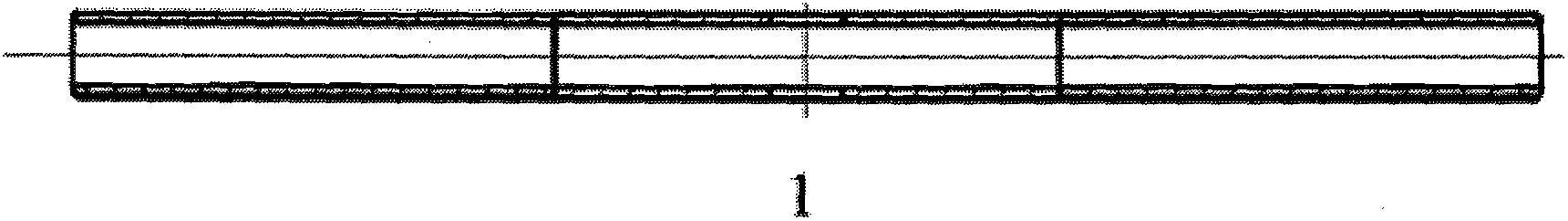

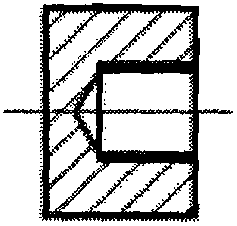

[0059] In a preferred embodiment of the present invention, as figure 1As shown in , a small diameter straight pipe butt welding device is provided, the device includes a hollow positioning mandrel 1, the middle part is provided with a vent hole 10, a plug nut 2 is screwed on one end of the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com