Slag cleaning plant for flame cutting machine

A flame cutting machine and slag cleaning technology, which is applied to gas flame welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of complex structure and insufficient safety of the slag cleaning device, and achieve simple structure and no mechanical wear. , the effect of simplifying the overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

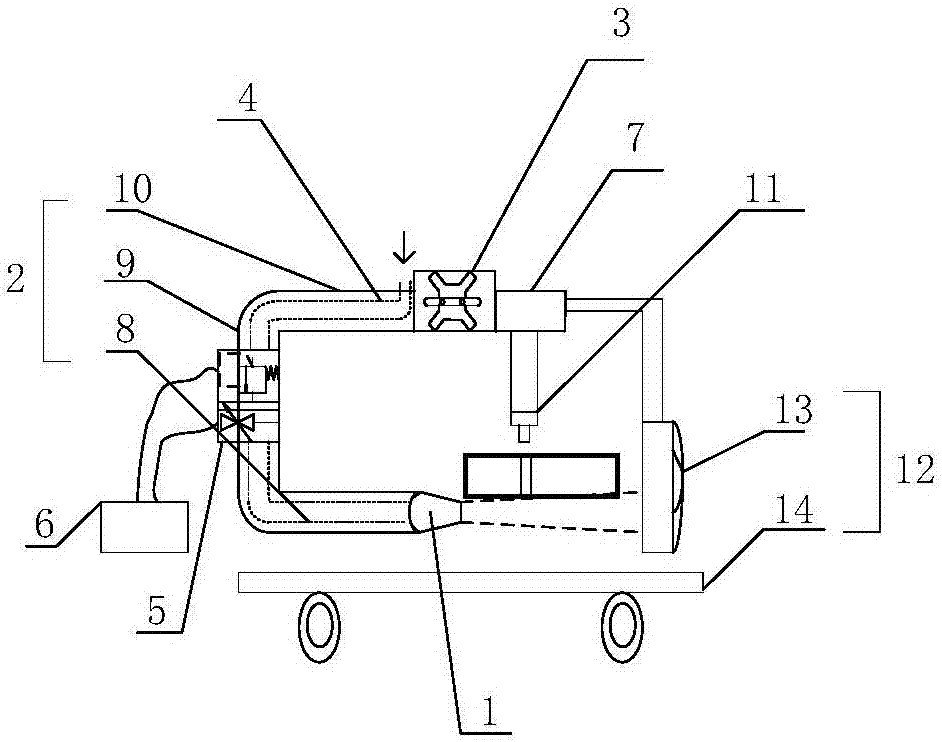

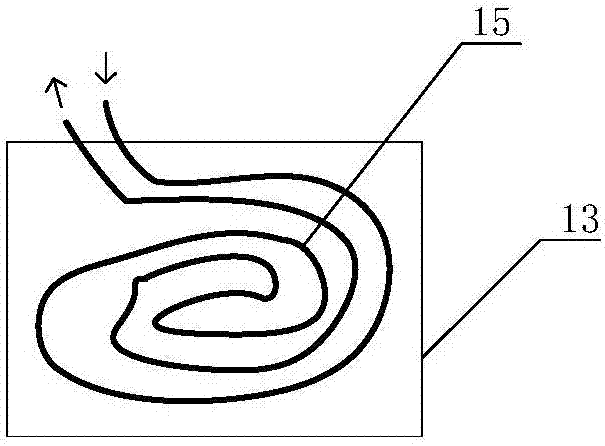

Embodiment 1

[0033] In order to solve the problems of complex structure and low safety existing in the slag cleaning device of the existing flame cutting machine, a device such as figure 1 The slag cleaning device of the flame cutting machine shown includes a slag blowing gun head 1 , a gun head bracket 2 , a fixed bracket 3 , an air inlet pipe 4 , a dual control valve 5 and a control device 6 . The slag blowing torch head 1 is connected to the cutting torch head guide rail 7 of the flame cutting machine through the fixed bracket 3, so that the slag blowing torch head 1 and the cutting torch head 11 move synchronously. The fixed bracket 3 includes two clamping parts, the position of the fixed bracket on the cutting gun head guide rail 7 can be adjusted by loosening the bolts (or other fixing parts) on the two clamping parts, and the end of the fixed bracket 3 is connected to the flame cutting On the device, for example, it is installed on the positioning clamp of the flame cutting device. ...

Embodiment 2

[0045] The difference between this embodiment and embodiment 1 is only:

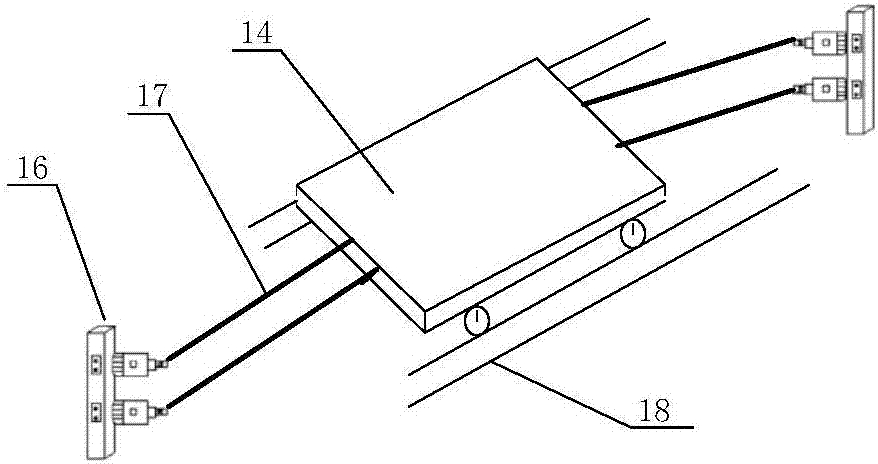

[0046] Such as image 3 As shown, the collecting plate 14 of the flame cutting machine slag cleaning device is slidingly connected with the channel steel 18 under the working platform of the flame cutting machine through the pulley at the bottom. Hand-operated device 16 and steel wire 17 are also set on collecting dish 14, and hand-operated device 16 is divided into two, and one is connected with the front end of collecting dish 14 by steel wire 17, and another is connected with the rear end of collecting dish 14 by steel wire 17. The side away from the working platform of the flame cutting machine is the front end. The hand-cranking device is a conventional reel structure, and the handles of different hand-cranking devices 16 are shaken, so that the steel wire pulls the collecting plate 14 to slide in different directions along the channel steel 18, and moves out of the working platform to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com