Material transportation and transferring structure

A material and conveying unit technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of heavy weight, increase, low efficiency, etc., to facilitate manufacturing and later maintenance, reduce safety risks, machinery The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

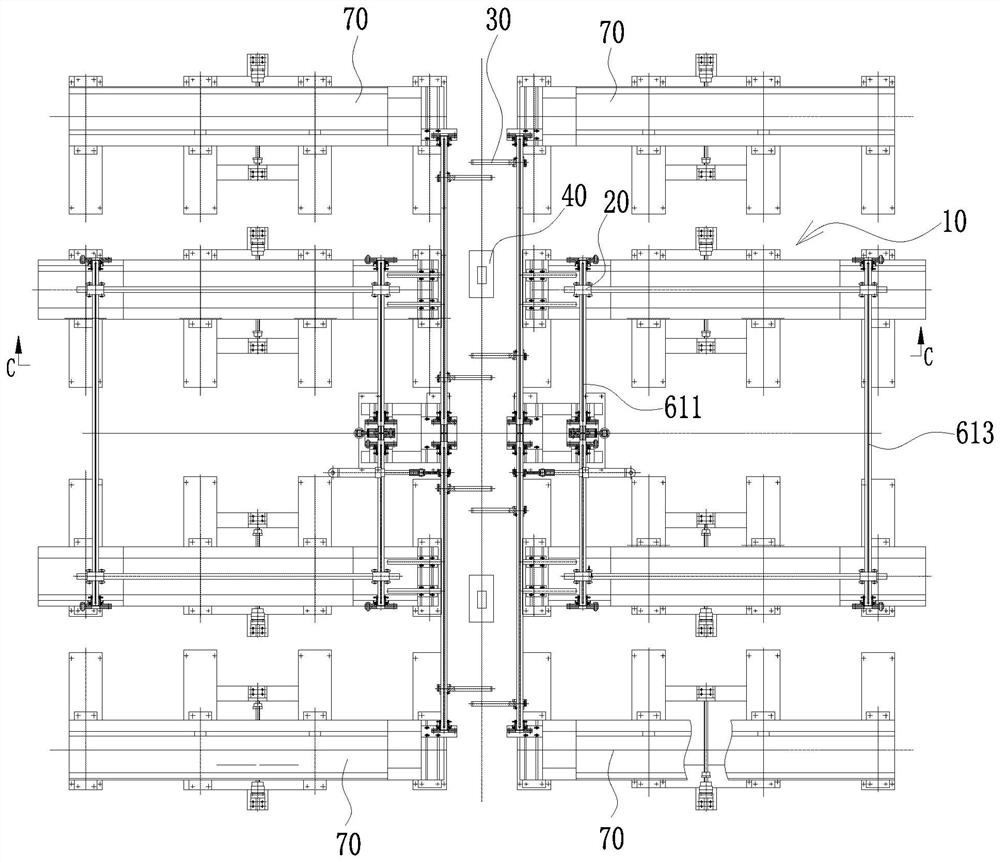

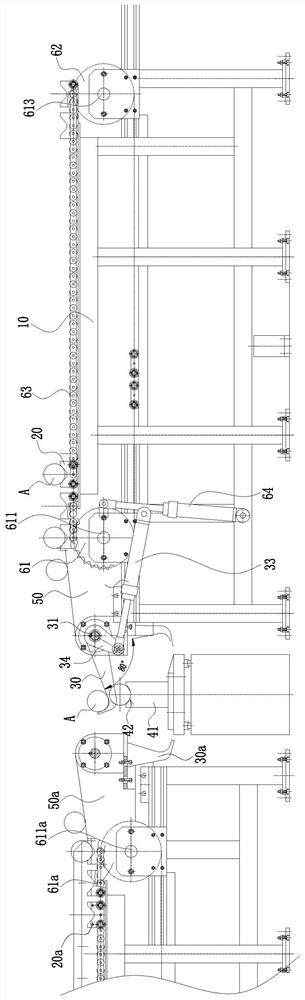

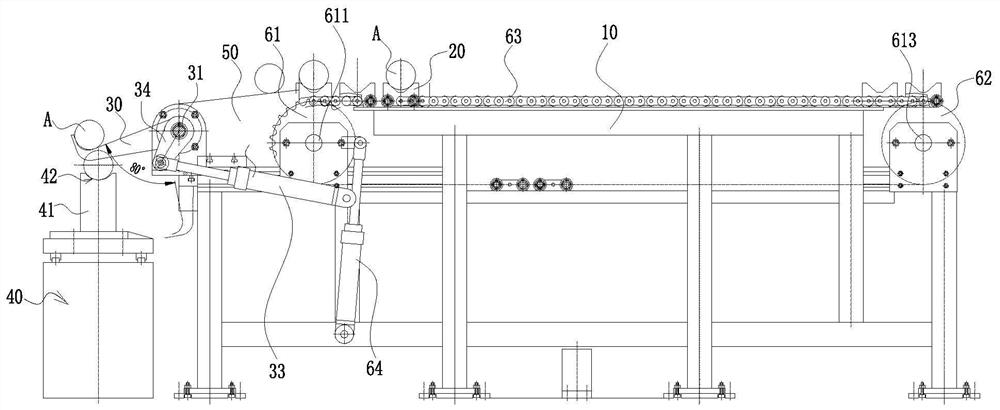

[0038] For ease of understanding, the specific structure and working method of the present invention will be further described below in conjunction with the accompanying drawings.

[0039]A material conveying and transshipment structure, comprising a frame 10, on which a first conveying unit for transporting shaft materials A is provided, and on the first conveying unit is provided a material conveying trolley that moves synchronously with it 20. The downstream end of the first conveying unit is provided with a transfer unit, the transfer unit includes a transfer hook 30, and the transfer hook 30 is in the upper position or the lower position when it swings under the action of the hook driving unit state blanking station, the swing end of the transfer hook 30 is hook-shaped for restraining the shaft material A; the transfer unit also includes a blanking table 40 for placing the shaft material A, and the blanking table 40 is located at the blanking station of the transfer hook ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com