High-precision passenger tire molding machine adopting two-time method

A molding machine and secondary method technology, applied in tires, applications, household appliances, etc., can solve the problems of asynchrony of cylinders, small radial stroke, poor repeatability, etc., and achieve good coaxiality, good repeatability, and alignment. good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific embodiment of the present invention will be described in further detail by describing the embodiments below with reference to the accompanying drawings, the purpose is to help those skilled in the art to have a more complete, accurate and in-depth understanding of the concept and technical solutions of the present invention, and contribute to its implementation.

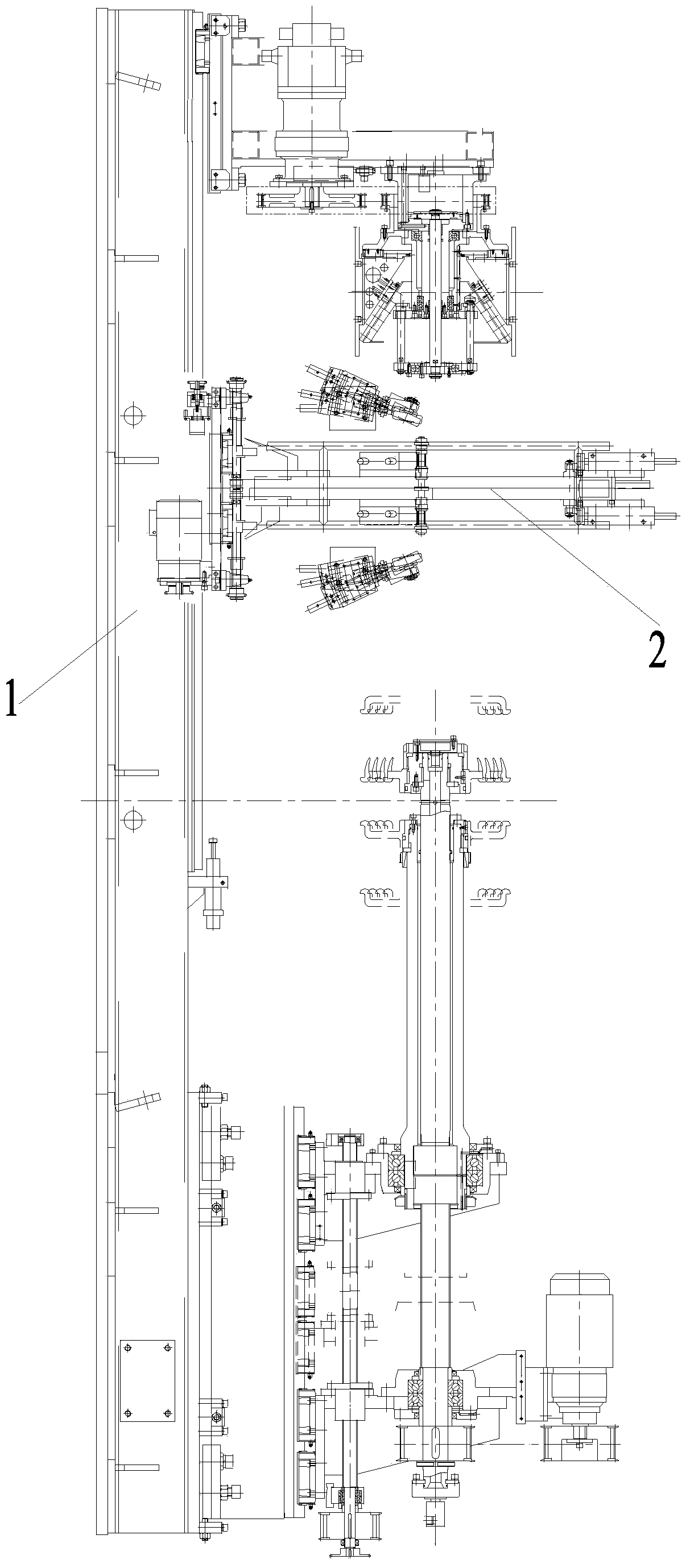

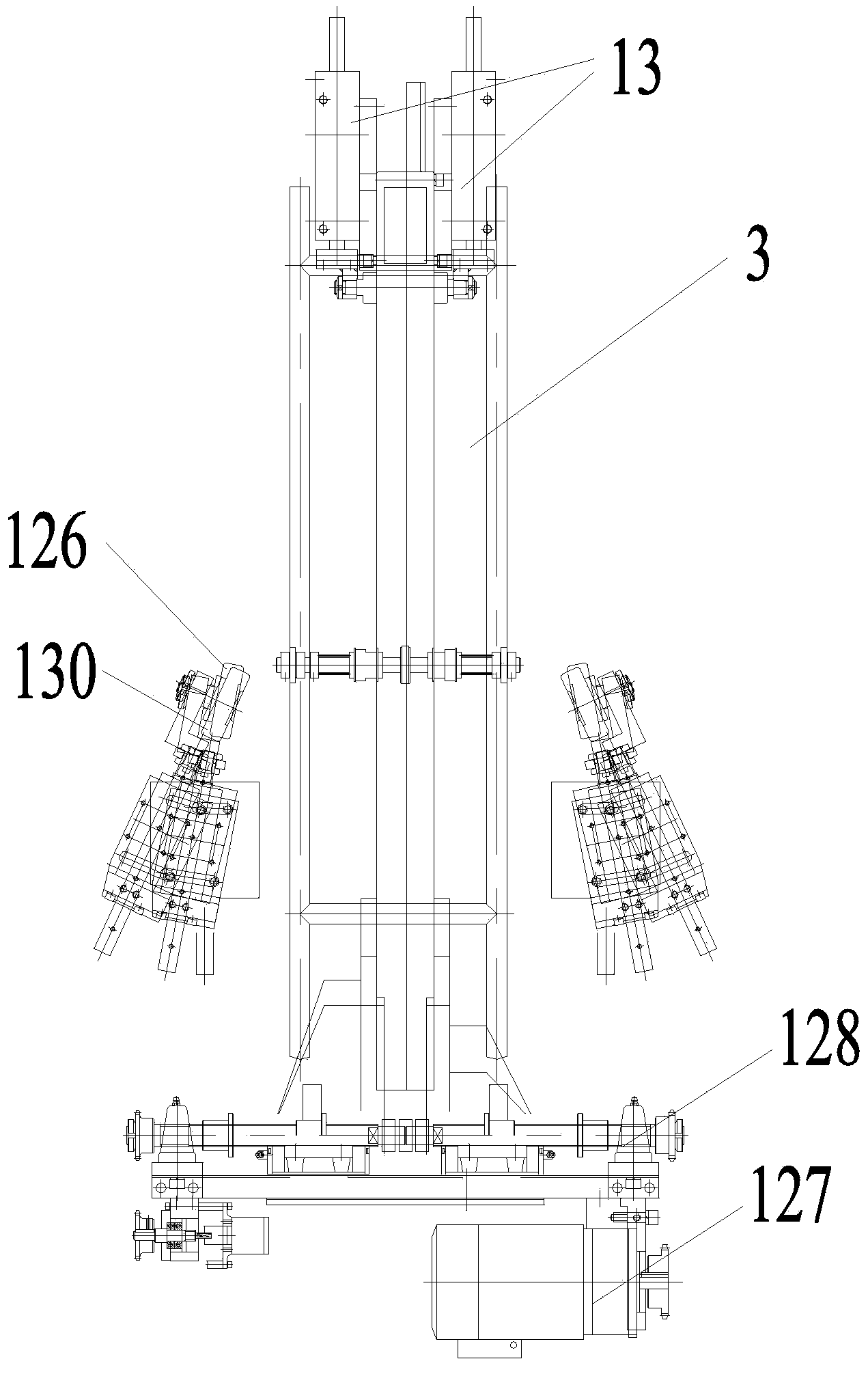

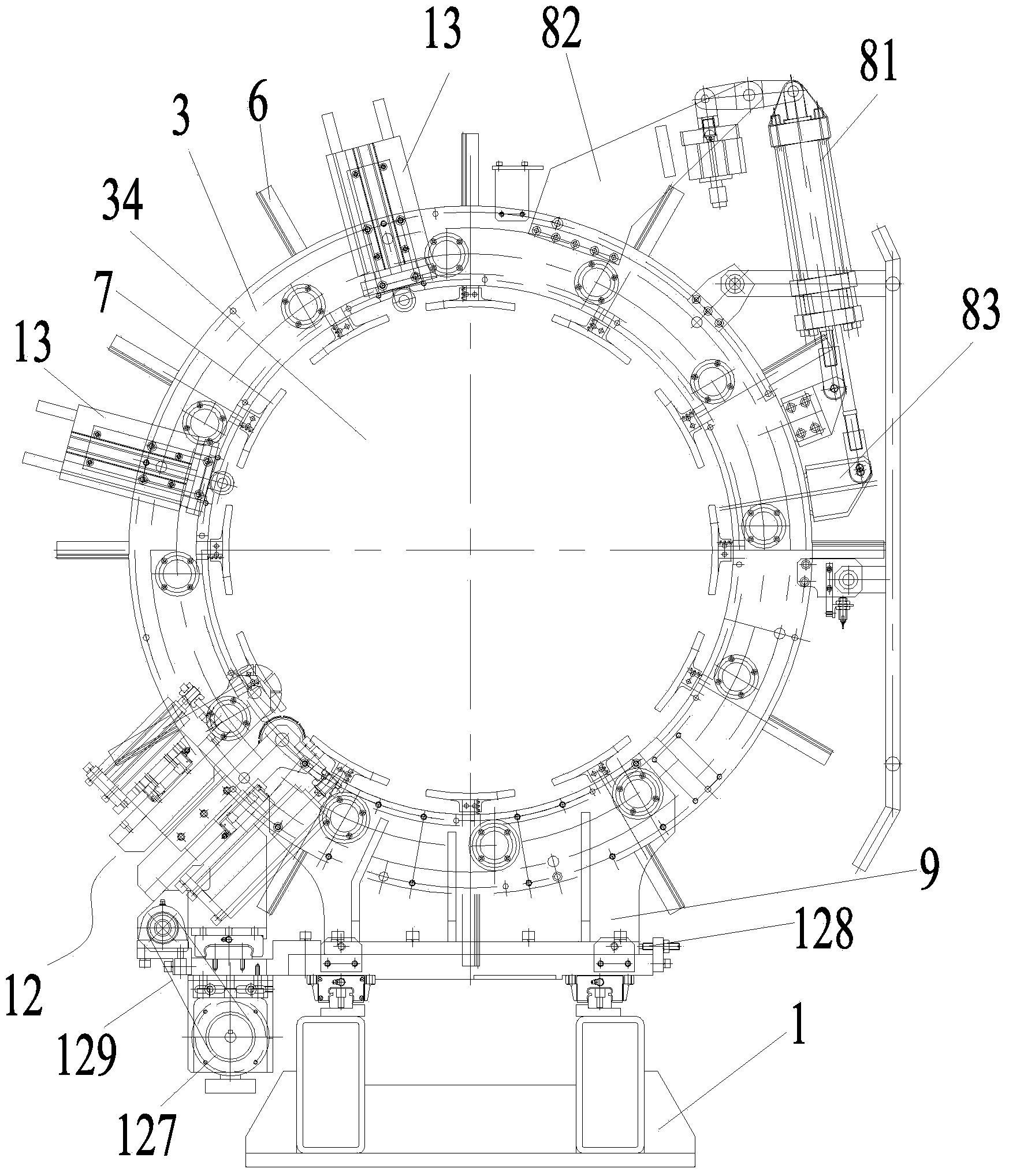

[0037] Such as Figure 1 to Figure 16 As shown, a high-precision passenger tire secondary molding machine includes a one-stage molding machine for making a carcass and a two-stage molding machine for making a tire crown and combining the tire crown and the carcass to form a green tire. The forming machine includes a section of base 14 and a main shaft assembly 15. A section of forming drum 10 is installed on the main shaft assembly 15. The second section of forming machine includes a second section of base 1 and a transfer ring 2 for transporting the crown. The transfer ring 2 includes a second se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com