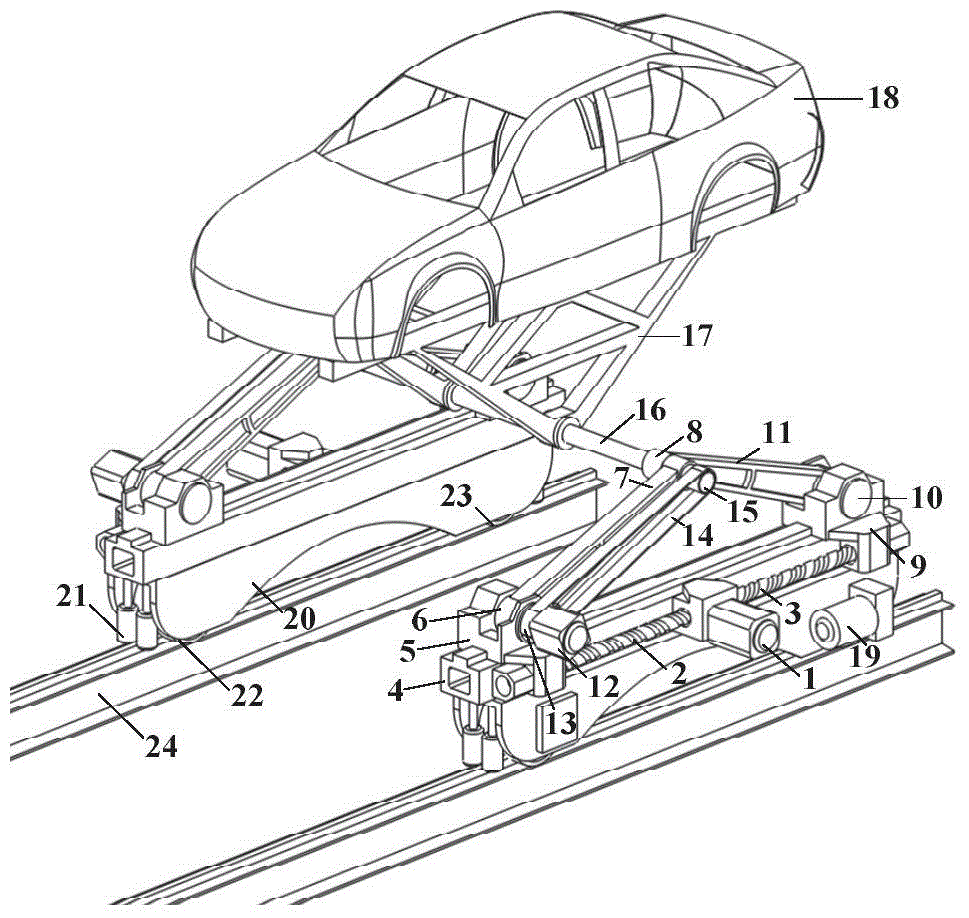

Synchronous coordinated control method of series-parallel automobile electrophoretic painting conveying mechanism

A conveying mechanism and electrophoretic coating technology, applied in electrolytic coating, electrophoretic plating, coating, etc., can solve problems such as difficult to obtain accurate dynamic parameters, difficult to control effects, and irreversible synchronization errors of connecting rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

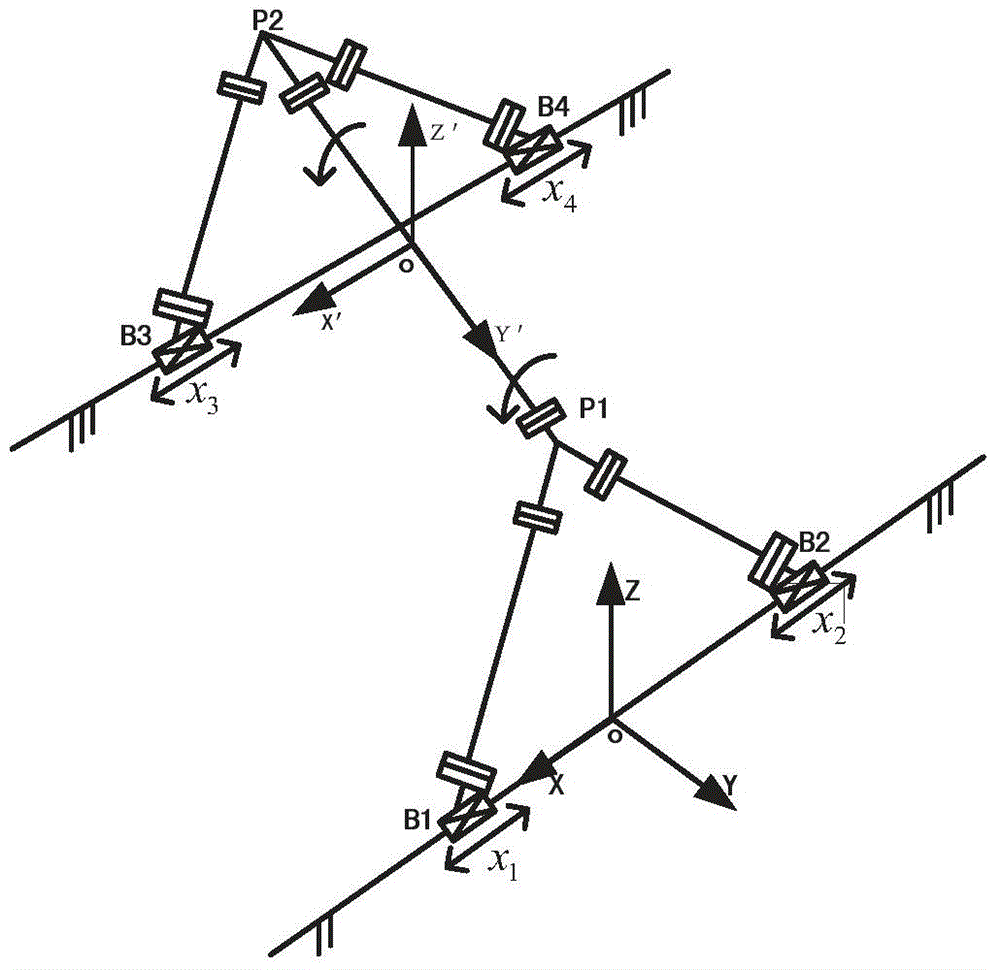

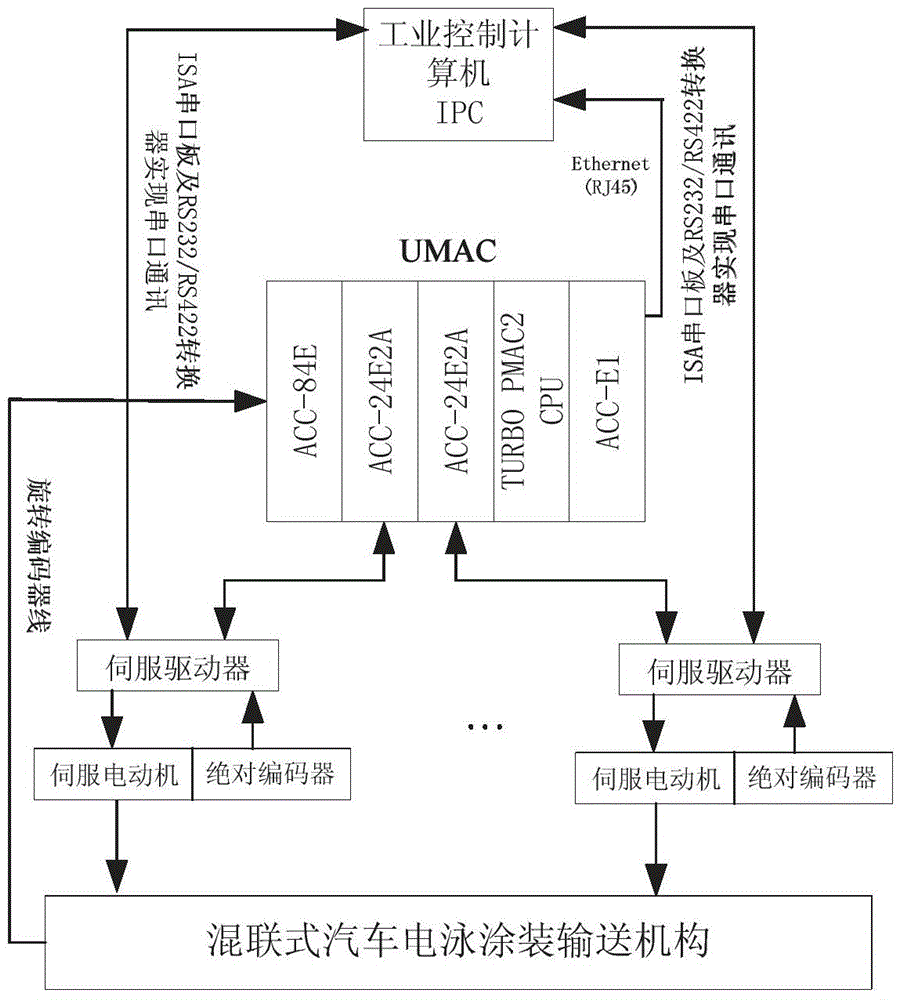

[0111] The Fangming control method mainly focuses on solving the synchronous coordination control problem of the hybrid automobile electrophoretic coating conveying mechanism with a synchronous coordination control technology, and realizes high-performance control of the mechanism. The specific implementation of this control method is as follows:

[0112] 1. Solve the Jacobian matrix

[0113] exist figure 2 In this method, the rod length constraint equation is used, and the kinematics inverse solution equation of the mechanism can be obtained according to the structure of the lifting and turning mechanism:

[0114] x 1 2 + z 1 2 = L 1 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com