Non-mean-value double-light-beam synchronous scanning laser selective melting device and light path synthesis method thereof

A technology of laser selective melting and synchronous scanning, which is applied in the direction of improving process efficiency, improving energy efficiency, and additive manufacturing, and can solve problems such as reducing molding quality and processing failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

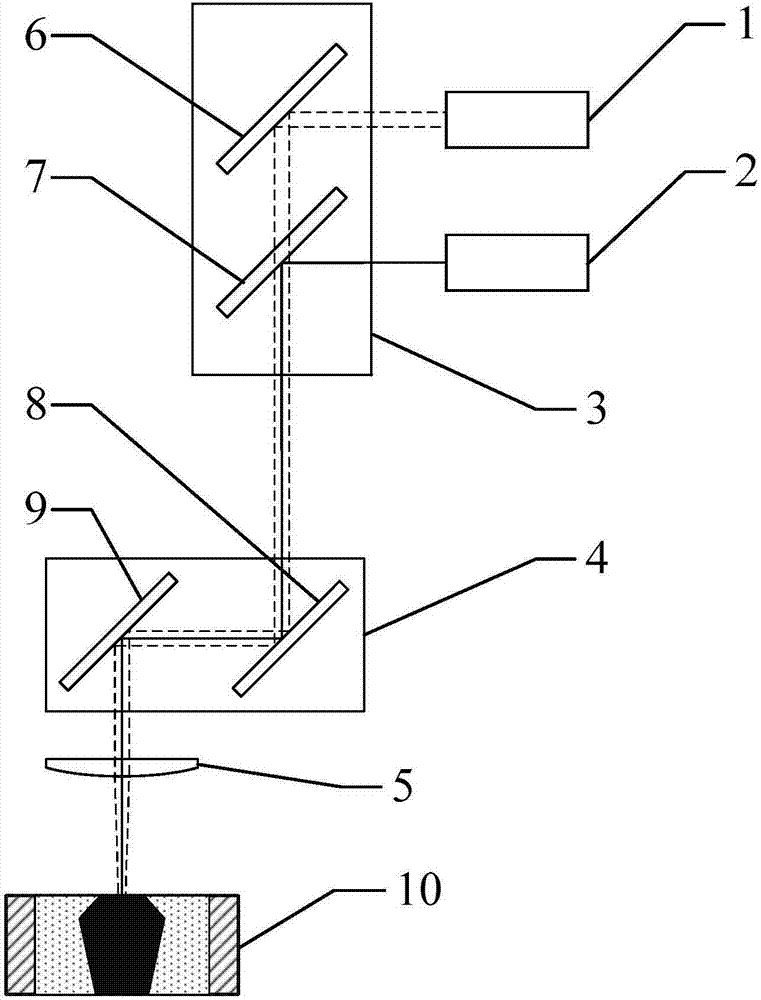

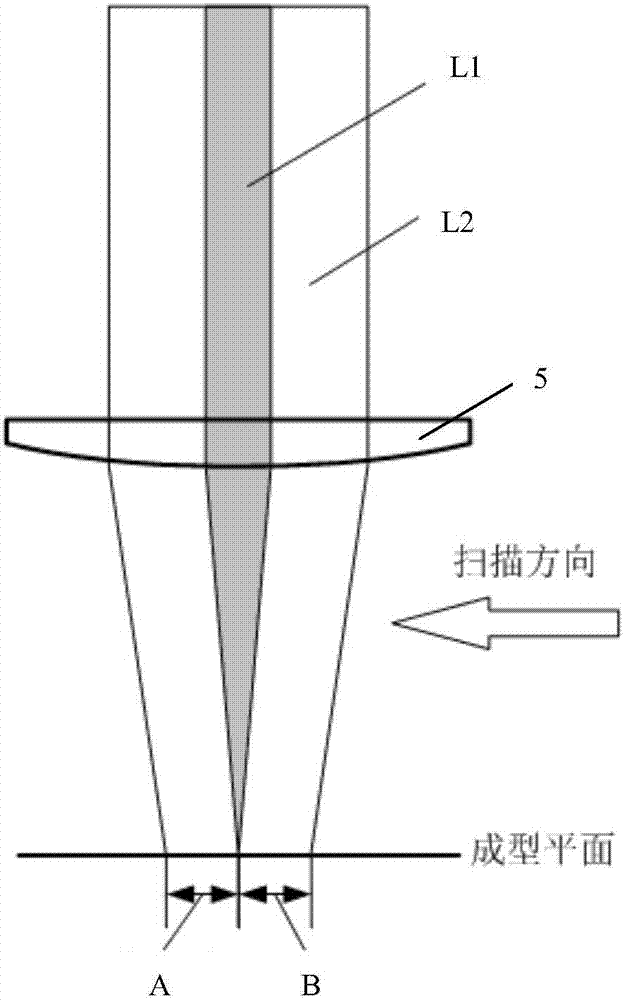

[0030] Such as figure 1 As shown, a double-beam synchronous scanning laser selective melting optical path device related to the present invention includes a large-spot laser beam incident device 1, a small-spot laser beam incident device 2, a laser beam combination assembly 3, an X-Y galvanometer scanning device 4, a field mirror 5, wherein the laser beam combination assembly 3 is composed of a large-spot reflector 6 and a small-spot transmission mirror 7, and the X-Y vibrating mirror scanning device 4 is composed of an X-axis vibrating mirror 8 and a Y-axis vibrating mirror 9.

[0031] Such as figure 1 The shown large-spot laser beam incident device 1 is provided with a large-spot laser incident interface, which is composed of optical components such as a collimator mirror and a beam expander, and its function is to adjust the non-uniform incident light of the large-spot laser into a flat top with uniform energy. Light beam, large spot laser beam incident device 1 can adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com