Three-segment synchronous drawer sliding rail

A slide rail and drawer technology, which is applied in drawers, home appliances, furniture parts, etc., can solve the problems of complex structure, short slide rail deployment length, and failure to meet user requirements, and achieve reliable transmission and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

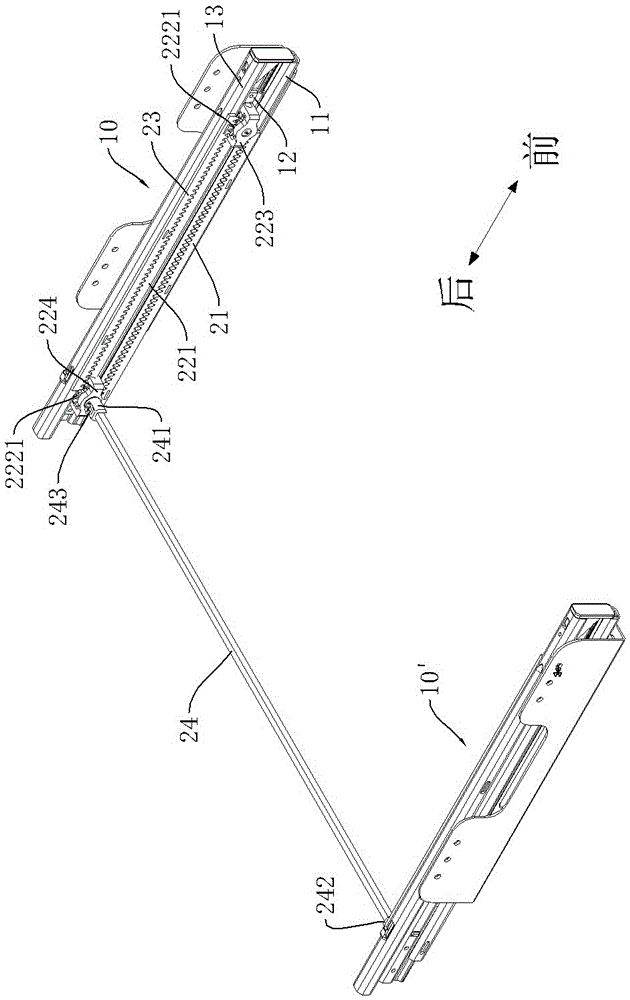

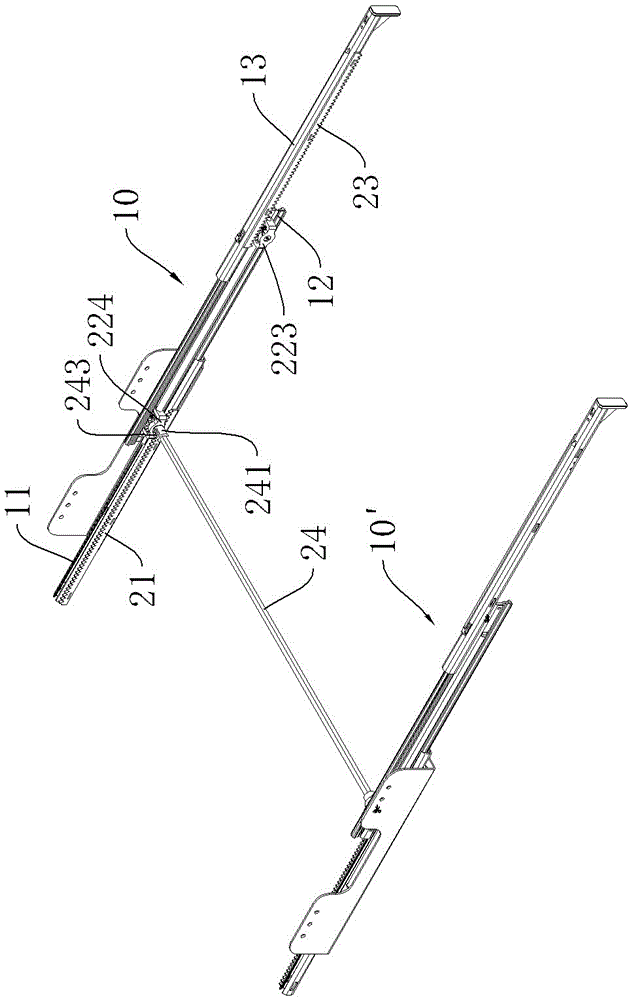

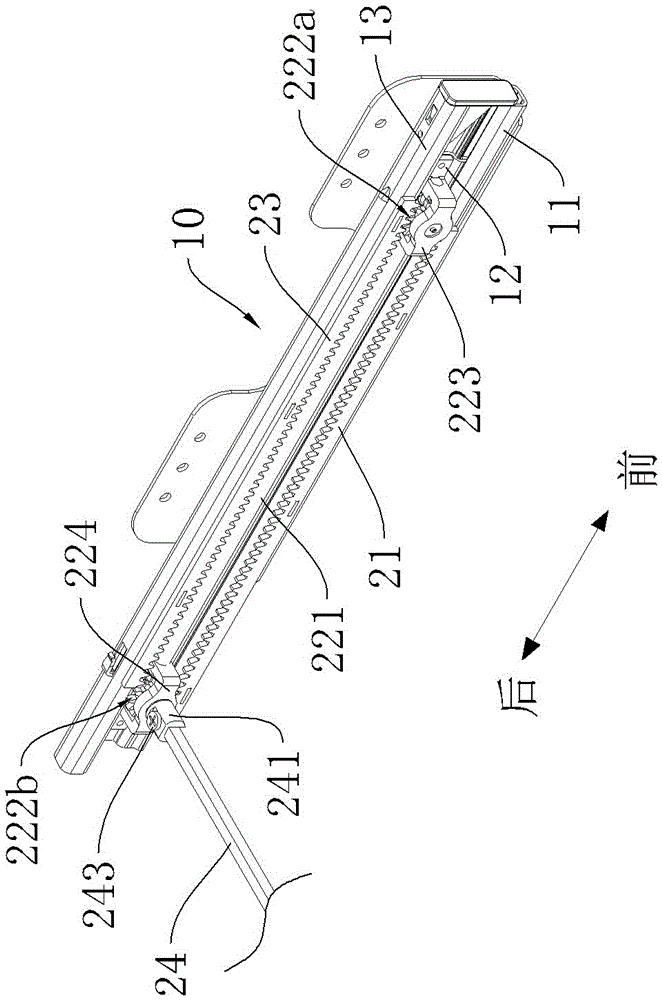

[0033] See Figure 1 to Figure 7 , the three-section synchronous drawer slide rail of the present invention includes two sets of slide rail assemblies 10, 10', the two sets of slide rail assemblies 10, 10' are installed on the left and right sides of the drawer respectively, and the two sets of slide rail assemblies 10, 10' Synchronization components 20 are respectively installed on the top, and the slide rail components 10, 10' all include the fixed rail 11 fixed on the inner wall of the cabinet through the fixed rail bracket 14, the movable rail 13 fixed on the outer wall of the drawer, and the fixed rail 13 respectively connected with the fixed rail bracket 14. Rail 11, movable rail 13 slidingly connected middle rail 12; synchronous assembly includes fixed rail rack 21, transmission mechanism 22 and movable rail rack 23, and fixed rail rack 21, transmission mechanism 22 and movable rail rack 23 are respectively installed on The fixed rail 11, the middle rail 12 and the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com