Double-acting servo pressure cylinder for press machine

A technology for booster cylinders and presses, applied in the directions of fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc. The effect of response speed and operation speed, improving flexibility and control accuracy, and reducing design cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

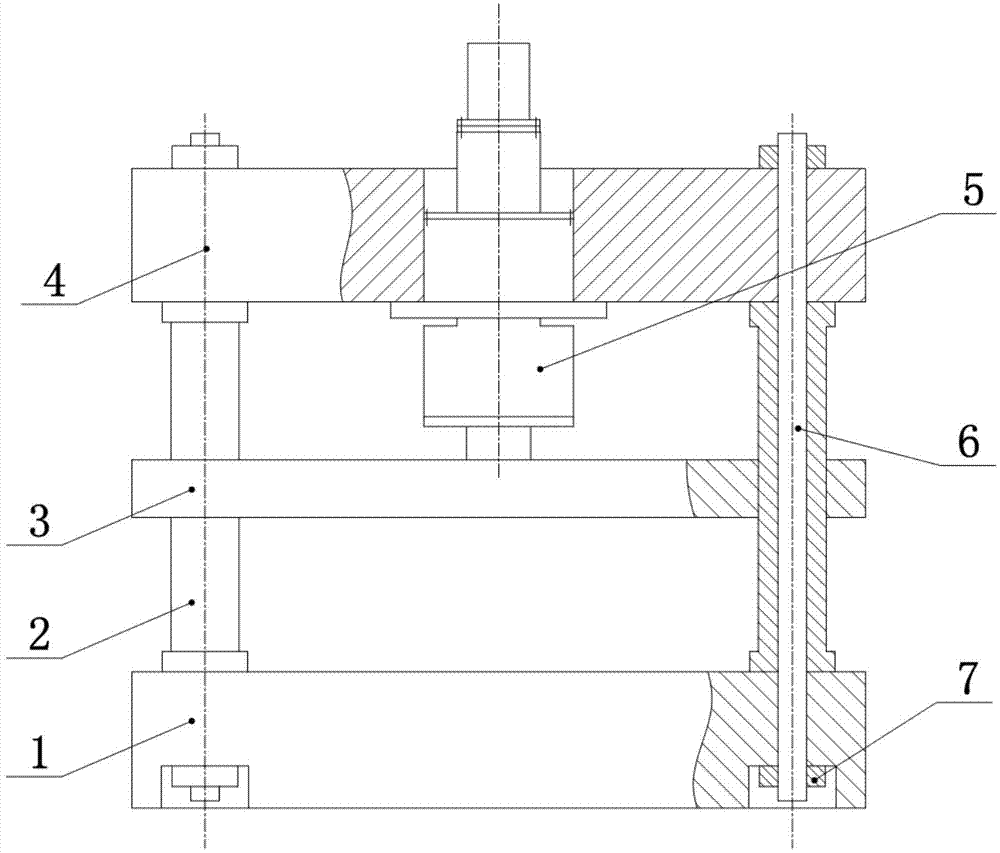

[0020] refer to figure 1 , a double-acting servo pressurized cylinder for a press, the fuselage mechanism is a three-beam four-pillar type, the fuselage mechanism includes a column 2, the column 2 is hollow, the tie rod 6 runs through the column 2, the outer surface of the column 2 is smooth, and the slider 3 is on the column 2 slides up and down, and the lock nuts 7 at both ends of the tie rod 6 fix the four uprights 2 between the beam 4 and the base 1, the double-action servo booster cylinder 5 is fixed on the beam 4 by bolts, and the double-action servo booster cylinder 5 The piston rod is connected with the slider 3.

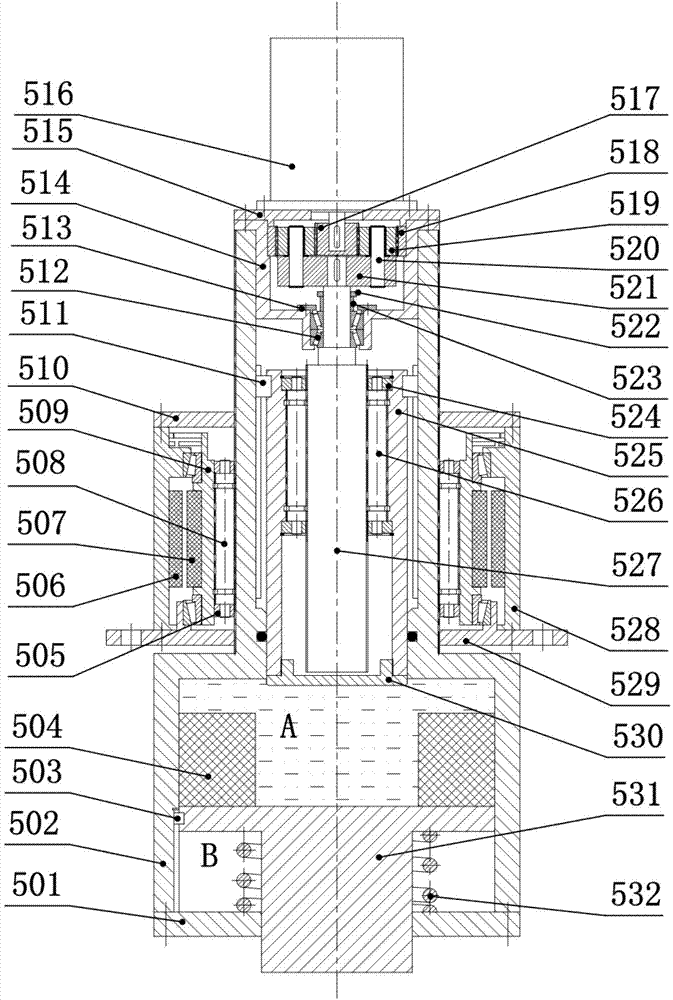

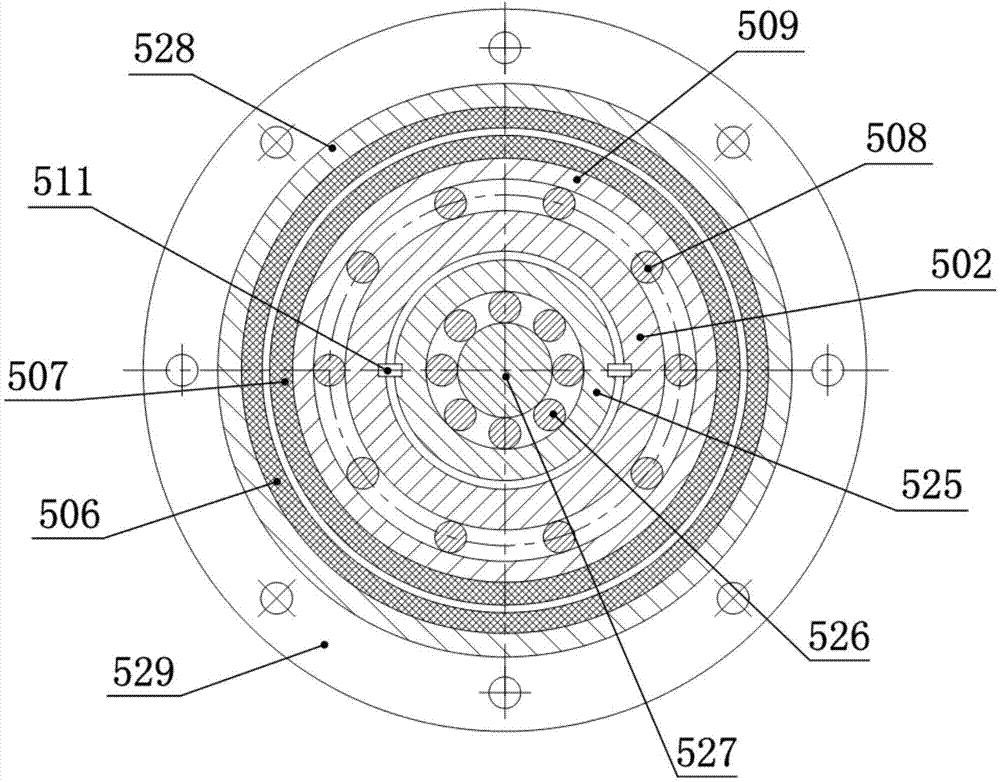

[0021] refer to figure 2 and image 3 , the double-action servo booster cylinder 5, the installation quantity is determined according to the actual nominal pressure, the double-action servo booster cylinder 5 includes an idle stroke device and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com