Pneumatic device with quick exhaust function

A pneumatic device and functional technology, applied in the direction of fluid pressure actuators, servo motors, servo motor components, etc., can solve the problems that cannot be further adjusted, affect the operating speed of pneumatic components, limit the exhaust speed of compressed air, etc., and achieve improved production Effects of efficiency, increased exhaust velocity, improved response speed and operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

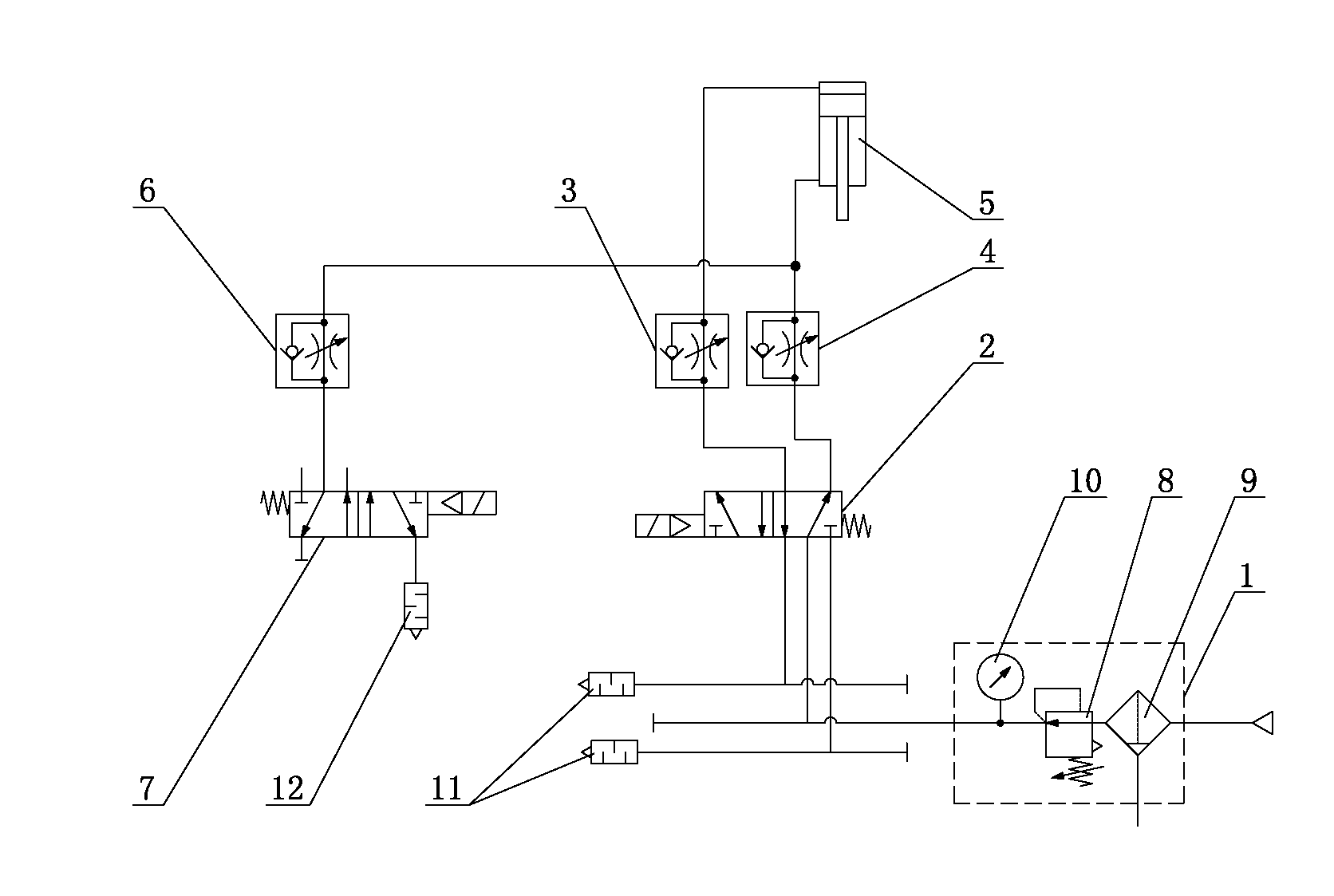

[0014] as attached figure 1 As shown, a pneumatic device with rapid exhaust function includes an air conditioning unit 1, a main circuit solenoid valve 2, a first speed regulating valve 3, a second speed regulating valve 4 and a pneumatic element 5. The air conditioning unit 1 1. Both the first speed regulating valve 3 and the second speed regulating valve 4 are connected with the main circuit solenoid valve 2, and the first speed regulating valve 3 and the second speed regulating valve 4 are connected with the first connecting hole and the second connecting hole of the pneumatic element 5 respectively. The exhaust speed regulating valve 6 is connected between the second connecting hole and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com