Shutter type vertical drying machine and material drying system adopting drying machine

A vertical dryer and drying system technology, applied in the direction of drying solid materials, drying, lighting and heating equipment, etc., can solve the problems of reducing material passages, failing to improve drying efficiency, and failing to meet the requirements at one time. To achieve the effect of increasing the exhaust velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

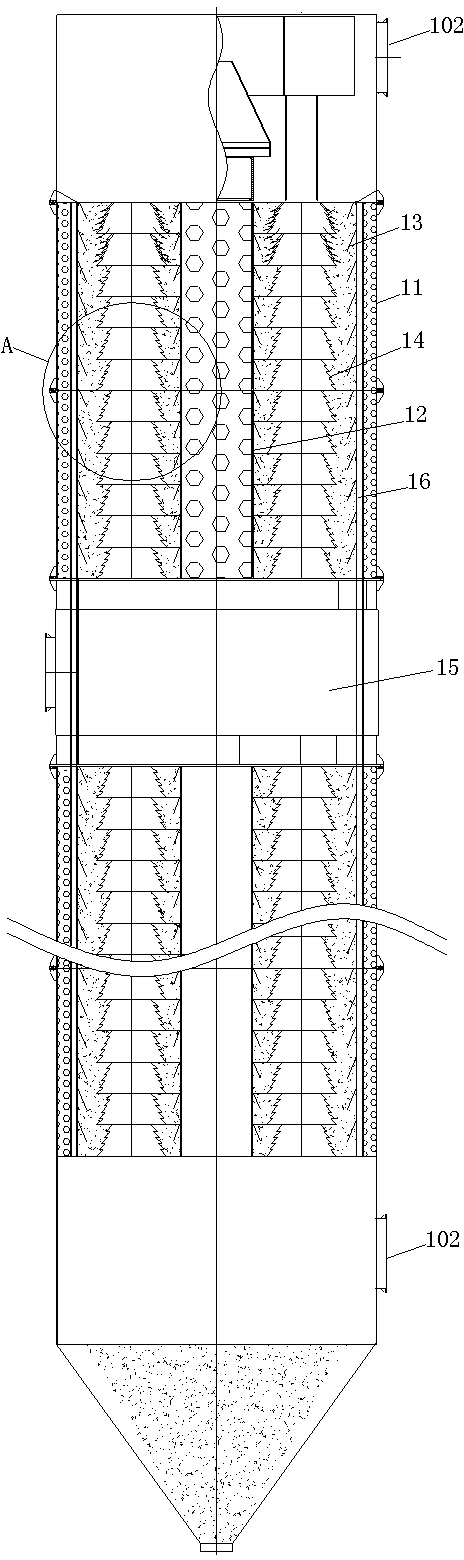

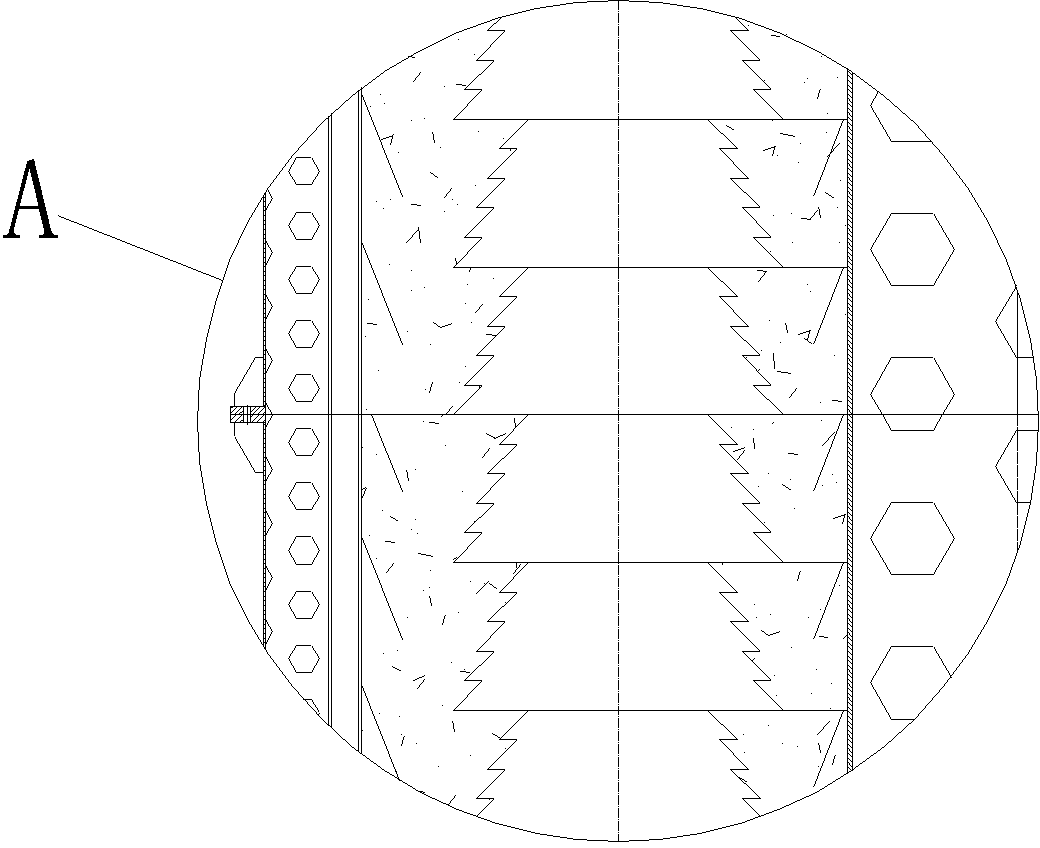

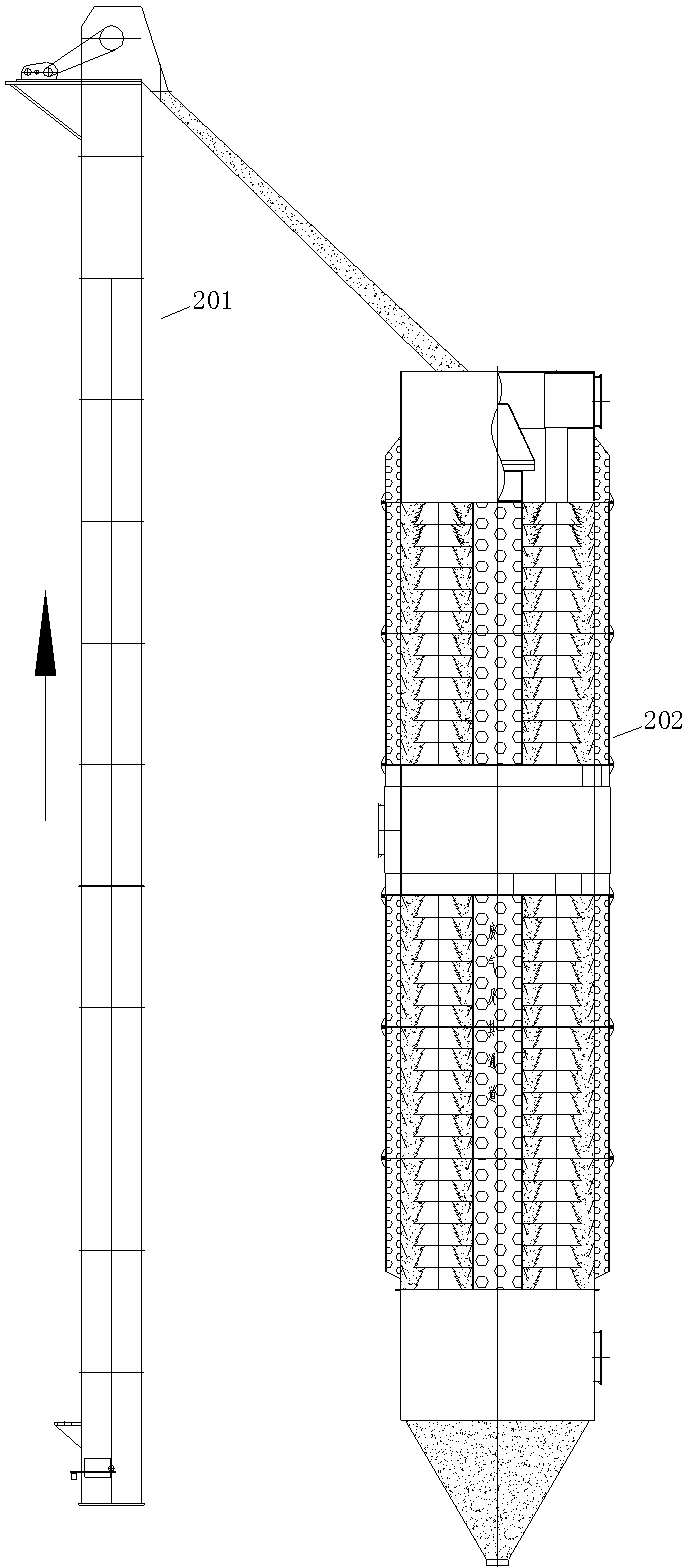

[0024] Examples of louver-type vertical dryers, such as Figure 1-2 As shown, the vertical dryer is a double-cylinder vertical dryer, which includes an outer cylinder 11, an inner cylinder 12, and a lifting plate 13 and a retaining ring 14 arranged between the inner and outer cylinders. Wherein the outer cylinder body 11 is a jacketed structure, and a waste gas channel 101 is arranged in the cylinder wall. In this embodiment, the dryer includes two drying sections, an upper and a lower one, and a waste gas discharge pipe 15 arranged between the two drying sections. In addition, each drying section is provided with a hot air inlet 102; the material retaining ring 14 is composed of a plurality of annular material retaining blades, in this embodiment, each material retaining ring 14 has five material retaining blades, which are connected by Ribs (not shown in the figure) are fixedly connected together and form a louver structure. Fixing the corresponding retaining blades through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com