Building material conveying device

A technology for conveying devices and building materials, applied in cleaning devices, conveyor objects, transportation and packaging, etc., can solve the problems of increasing the amount of cement overflow and seepage, large impact force, and increasing dust, so as to reduce cement overflow and impact. force, the effect of increasing the exhaust velocity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

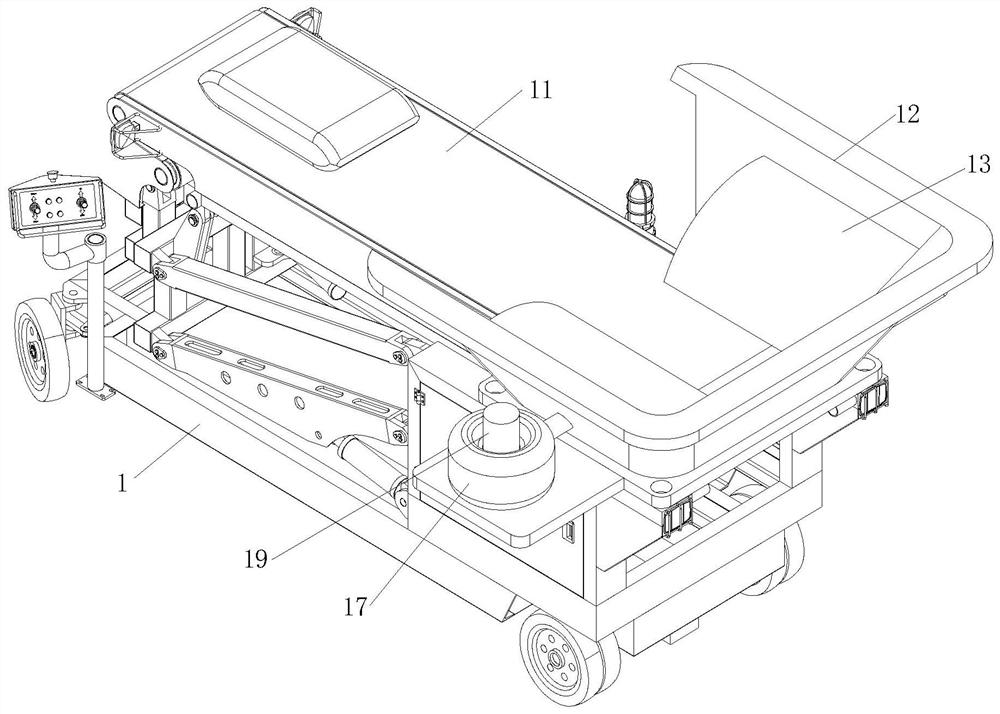

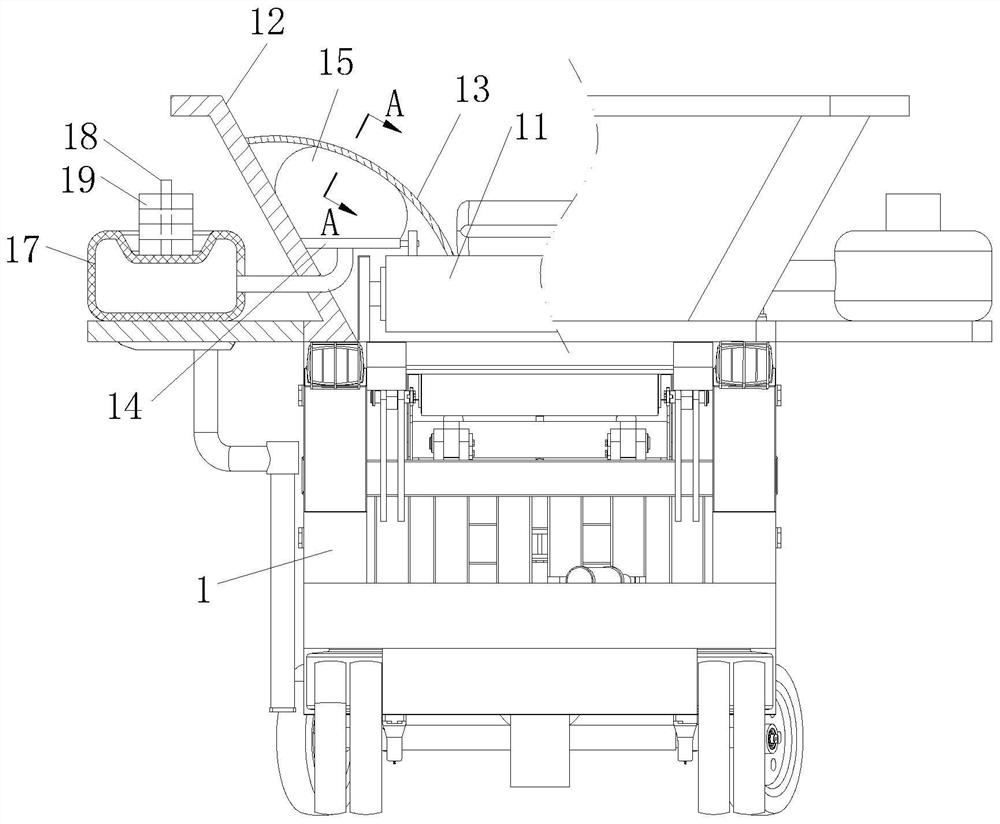

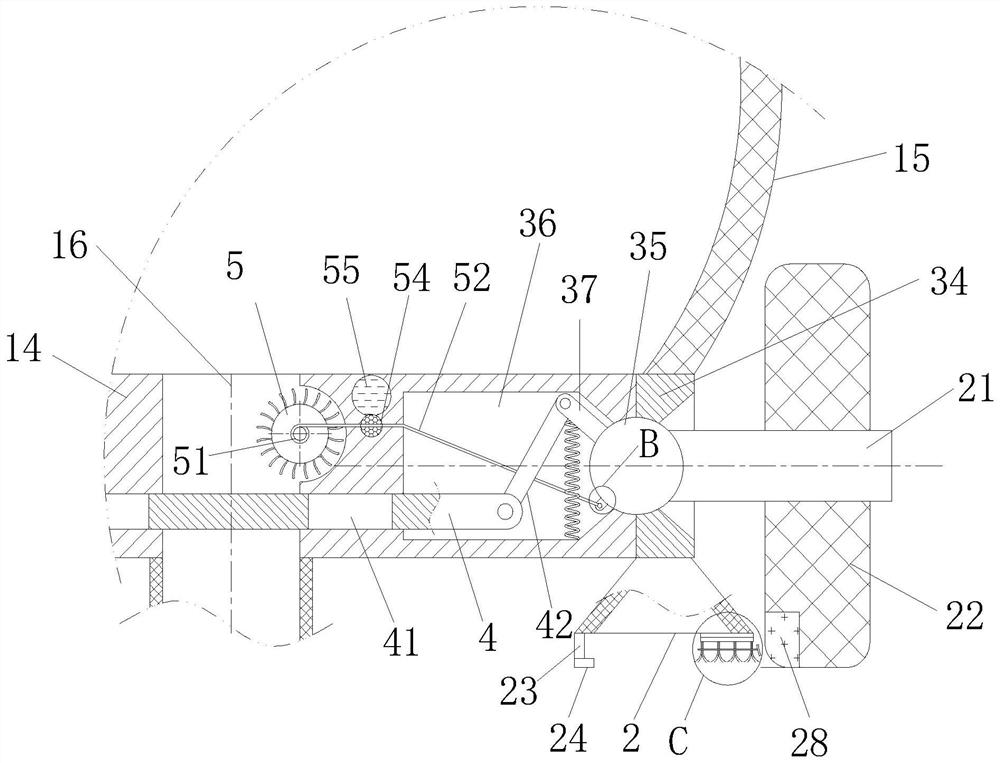

[0030] like Figure 1 to 5 As shown, a conveying device for a building material according to the present invention includes a body 1, a conveyor belt 11, and a feed strip 12; the feed hopper 12 is placed at the end of the conveyor belt 11, and the feed bucket 12 An opening is provided on one side of the conveyor belt 11; the inner wall of the hopper 12 is located on the conveyor belt 11, and there is a pair of buffer curtains 13, the top of the buffer curtain 13 and the side away from the opening 12 Inner wall solid connection; the inner wall of the core strip 12 at the bottom of the buffer curtain 13 is secured by the flexible air bag 15 by the plate plate 14, and the bracket 14 is opened with the valve hole 16 communicating with the air bag 15; when working, existing The packaging bag of the packaging cement is a woven bag. There are many fine gaps on the woven bag. The cement is easily oozing from the bag, causing more cement powder to attach a large cement powder on the packagi...

Embodiment 2

[0040] like Image 6As shown, one end of the rotation shaft 51 is provided with a gas pump, and the rotation shaft 51 is fixed to the input shaft of the air pump; the buffer curtain 13 is closer to one side of the gas bag 15, a set of elastic ribs 6, and the ribs 6 open There is a spray hole 61 in communication with the air pump; one side of the rib 6 is in contact with the air bag 15, and the nozzle 62 communicating with the air hole 61; reducing the pleats of the curtain 13 through the rib 6, increasing the reduced cement bag The wear between the buffer curtains 13, and the air pump is intermittent to the air hole 61, so that the compressed air hole discharge hole 62 is ejected, so that the ribs 6 form an air gap between the ribs 6, further reduce the air bag 15 and the buffer. Wear during the deformation process of the curtain 13, extending the service life of the air bag 15.

[0041] When working, the present invention is supplied with a curtain 13 in the feed strip 12, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com