Electronic tag packaging equipment

A technology for electronic labels and packaging equipment, which is applied in the direction of circuits, electrical components, and record carriers used by machines. It can solve the problems of high friction of guide rail sliders, affecting the accuracy of chip loading, and high cost, so as to reduce the distance of movement and increase the cost. The effect of operating speed and increasing the rigidity of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below with reference to the accompanying drawings, and the features and specific embodiments of the present invention will be clarified.

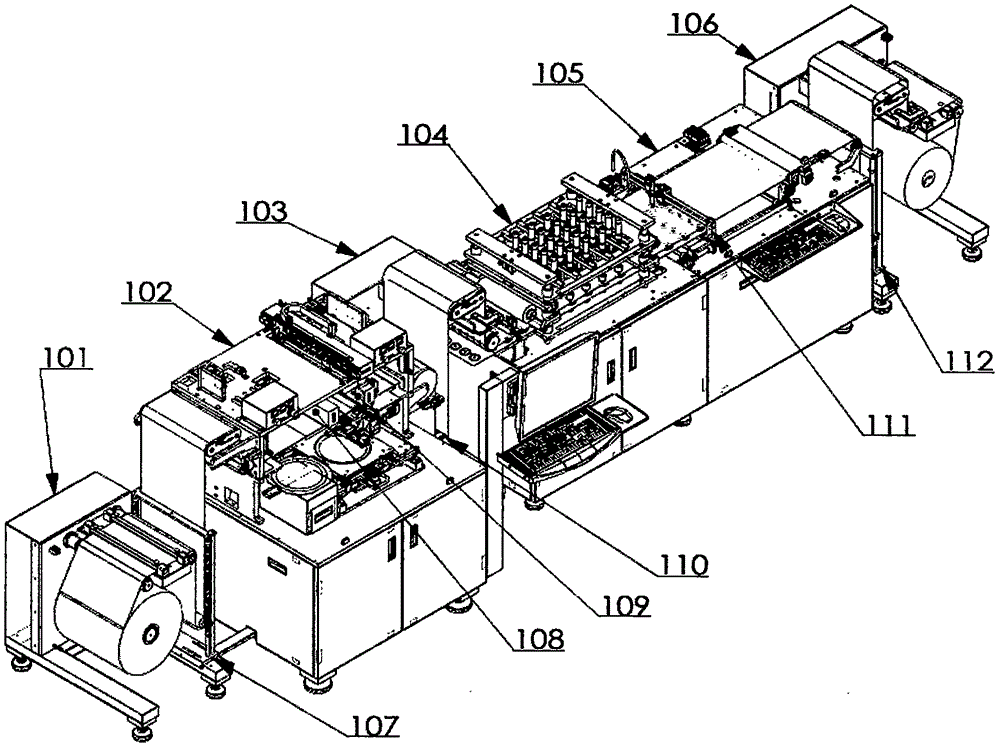

[0036] figure 1 It is a schematic diagram of the overall structure of the present invention, depicting the positions of various parts on the complete machine equipment.

[0037] The wire film to be produced is output from the feeding part 101 and reaches the flip chip part 102, where the dispensing arm 108 and the bonding arm 109 are respectively responsible for the work of dispensing and bonding. The antenna film with the chip installed is then transported to the heat pressing part 104 through the intermediate tension and deviation correction part 103, and the intermediate tension mechanism 110 is responsible for providing tension and controlling the redundant antenna. The chip and antenna go through a hot pressing process for a few seconds to solidify the glue, fix the chip, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com