Nondestructive testing robot intelligent testing method based on virtual reality technology

A virtual reality technology and robot intelligence technology, applied in nuclear power generation, computer-executed nuclear control, reduction of greenhouse gases, etc., can solve problems such as low efficiency of non-destructive testing, frequent adjustment of testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

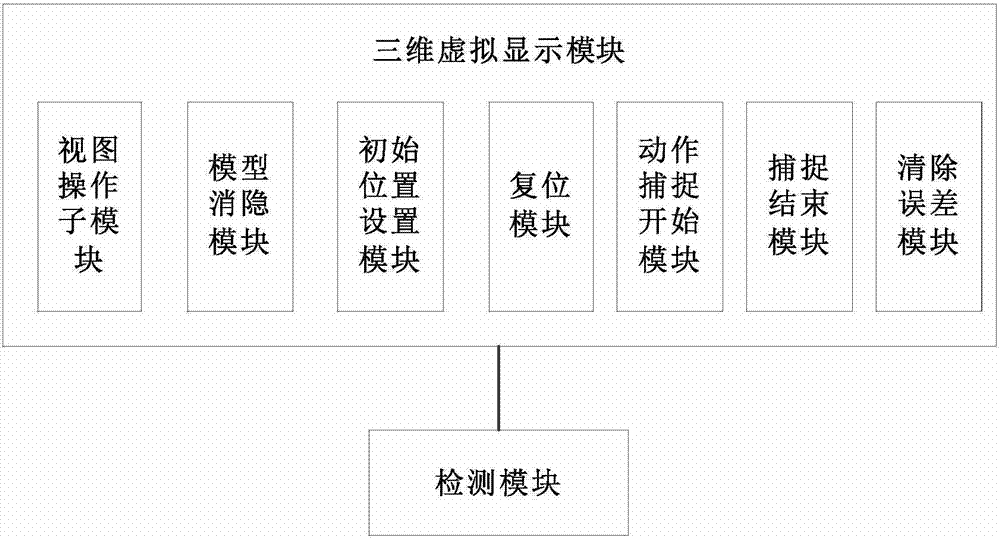

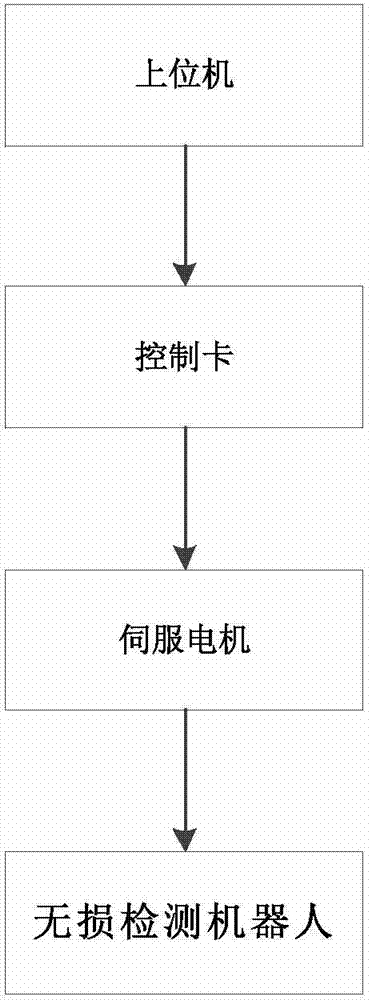

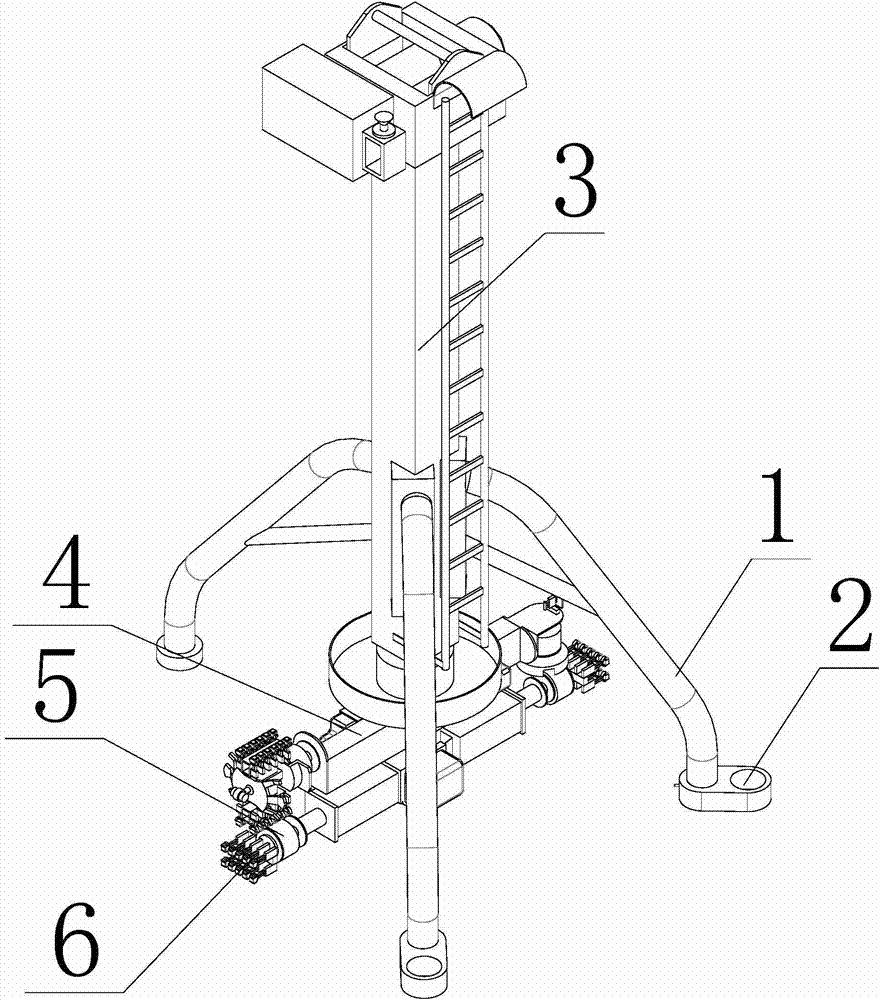

[0082] Such as figure 1 As shown, the non-destructive testing robot intelligent detection system includes the use of virtual reality technology to construct the non-destructive testing robot simulation model and the reactor pressure vessel simulation model, and is used to install the non-destructive testing robot for non-destructive testing into the reactor pressure vessel to be tested The predetermined position of the non-destructive testing robot; after restoring each motion axis of the non-destructive testing robot to the initial state, and calibrate the end position of the motion axis of one degree of freedom, determine the working zero point; and construct the global coordinate system and axis coordinate system with the working zero point as the zero point coordinate; make the non-destructive testing robot A three-dimensional virtual display module that establishes a corresponding relationship between the simulation model of the detection robot and the simulated calibrated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com