A high-efficiency, safe and environmentally-friendly mining method for irregular strip-shaped distribution of poor and shallow buried seams

A safe, environmentally friendly, mining method technology, applied in open-pit mining, safety devices, mining equipment, etc., can solve the problems of waste dumps occupying valuable land, waste dumps polluting the environment, and backward mining planning, etc., to achieve comprehensive mining costs The effect of reducing, shortening the transportation distance and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention adopts open-pit mining mode, and concrete steps are as follows:

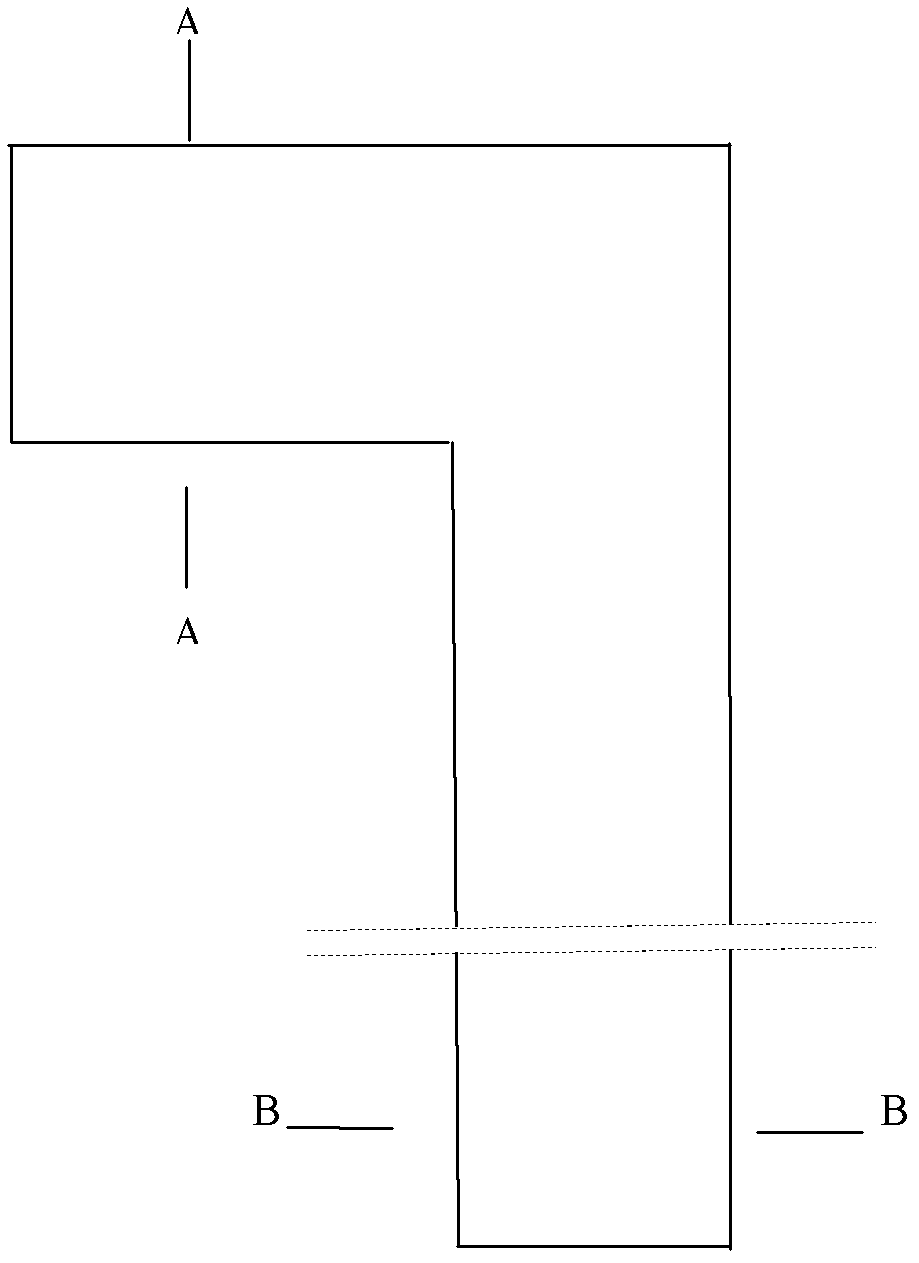

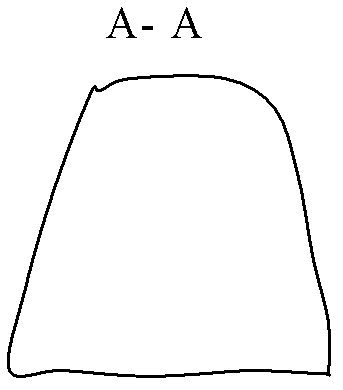

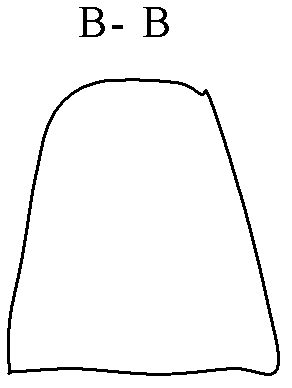

[0036] 1) For irregular strip-shaped thin and shallow buried ore seams, open-pit pits are arranged along the strike of the ore seam, and operations are carried out sequentially along the strike direction, see Picture 1-1 , Figure 1-2 , Figure 1-3 with figure 2 ;

[0037] 2) The mining operation platform is arranged in steps, and the transportation roads, mine roads and temporary drainage facilities are arranged;

[0038] 3) The method of stripping and mining by open-air step deep hole blasting is adopted. Specifically, the method of avalanche blasting is used to break rocks, and buffer blasting technology is used to excavate the slope. To the dump site, the ore is transported out of the mine for disposal; the stripped waste rock is backfilled into the goaf of the first mining section.

[0039] The waste rock stripped by the mining is backfilled to the goaf of the first mining...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com