Transport method of building longitudinal composite bridge in middle of strip mine stope

A transportation method and technology of combined bridges, which are used in open-pit mining, earthwork drilling, special mining, etc., can solve the problems of large material transportation distance, high mining intensity, and long working line, so as to reduce transportation costs and reduce transportation. distance, the effect of improving economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

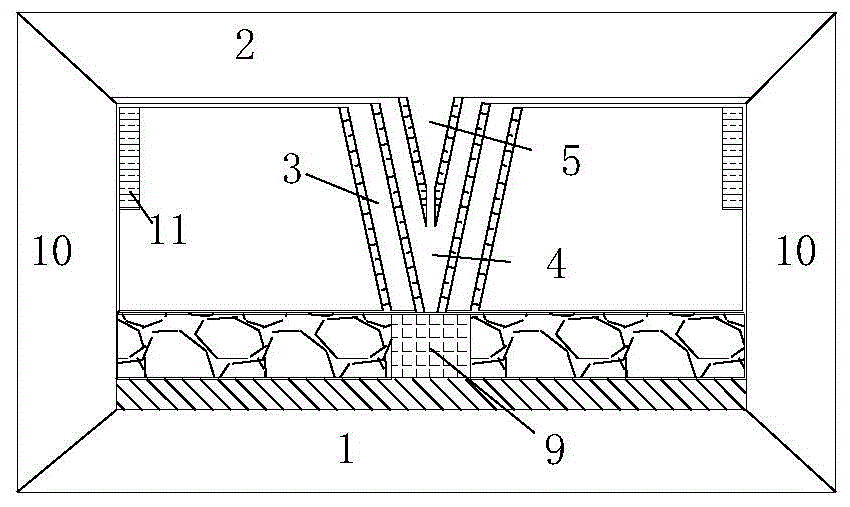

[0019] Example 1, the middle of the lower part of the open-pit mine of the present invention build a vertical composite bridge transport method, including stripping topsoil, until the bottom of the coal seam, forming an open-pit pit, the steps are as follows:

[0020] a. Utilize mining machinery to excavate a 1 / 3-1 / 2 year-long trench 9 in the direction of the coal seam in the middle of the pit bottom, and then backfill the trench 9 with the stripped material and compact it;

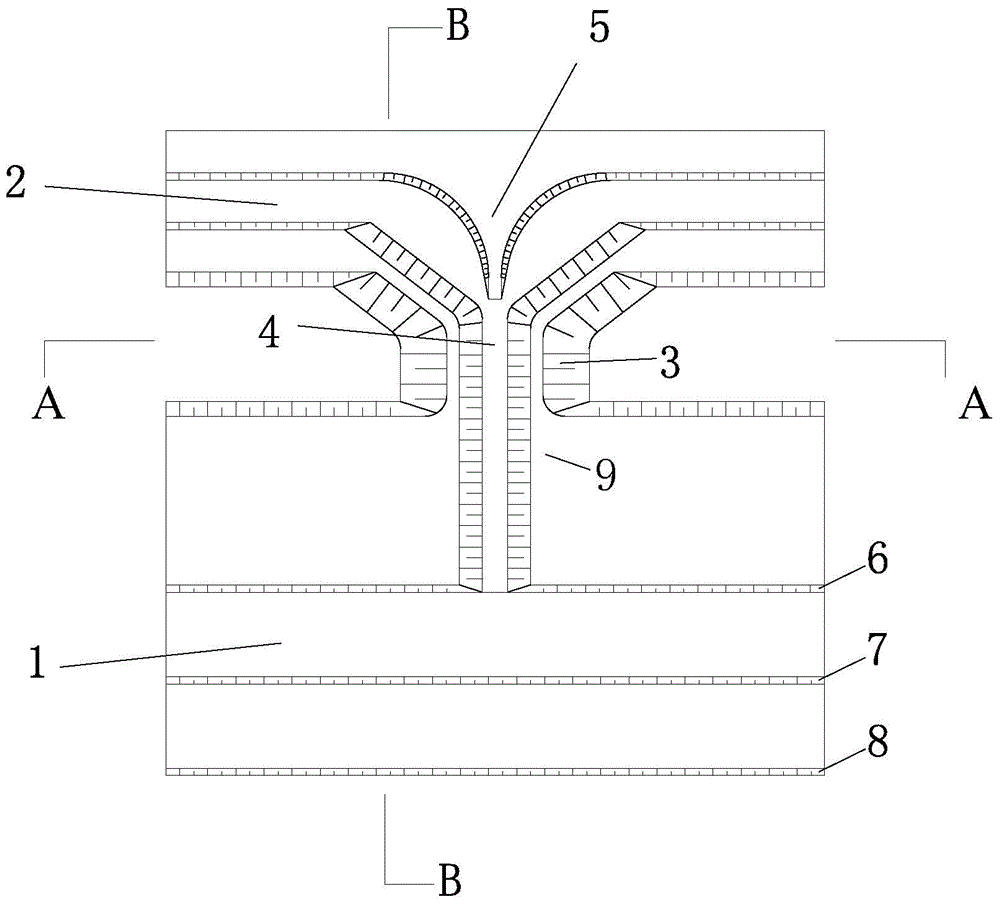

[0021] b. Build a longitudinal composite bridge between the working side 1 and the soil-discharging side 2, first build the foundation bridge 3 with stripped materials from the trench 9 to the side of the soil-discharging side, connect the working side 1 to the side of the soil-discharging side 2, and then build the foundation bridge 3 on the foundation bridge 3, a sub-bridge 4 is built above, and the height of the sub-bridge 4 is the same as that of the on-site stripping step; the stripping material of th...

Embodiment 2

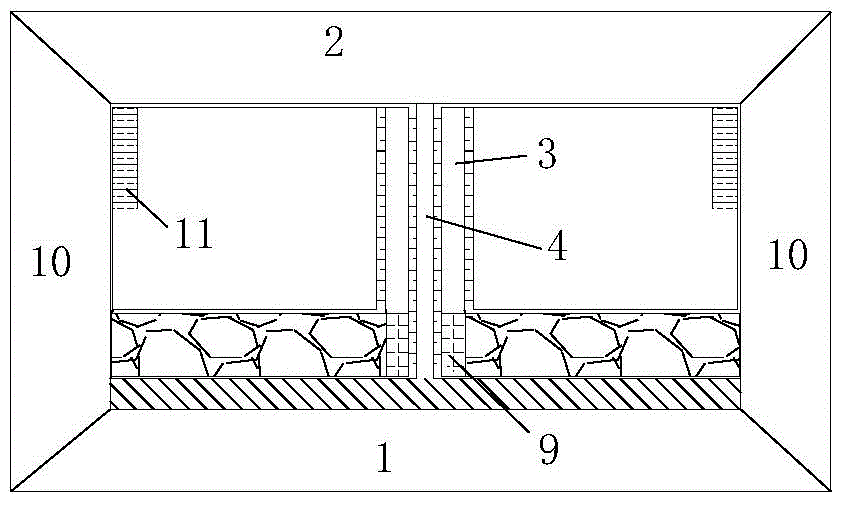

[0025] Embodiment 2 is basically the same as Embodiment 1, and the same points are omitted. The difference lies in that the intermediate longitudinal composite bridge built inside the stope is a linear stacked bridge, and the width of the base bridge passing through the stope remains unchanged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com