Mining method for recycling long-thick ore body hanging wall ore and transforming strip mine to underground mine

A technology of open-pit mining and mining methods, which is applied in open-pit mining, underground mining, surface mining, etc., can solve problems such as production capacity imbalance, safety accidents, and complex time-space relationships, and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

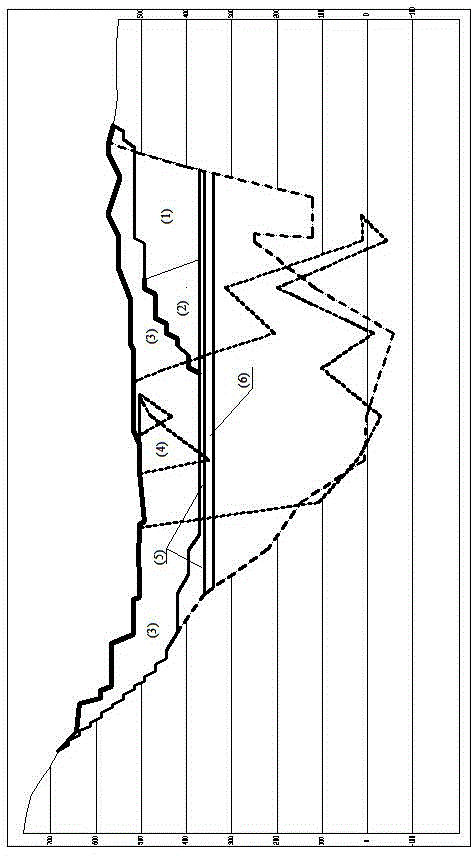

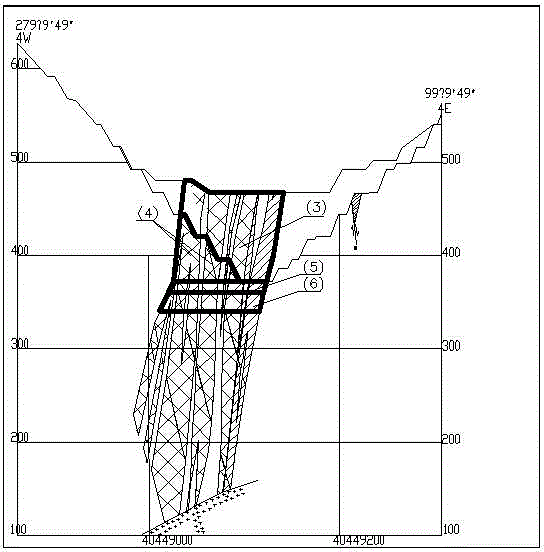

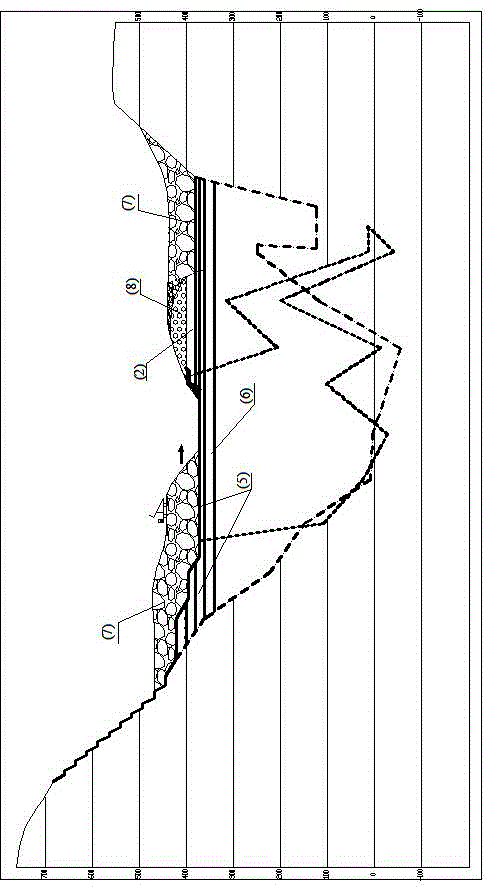

[0032] Below in conjunction with the accompanying drawings, the mining method of side ore recovery of Changhou ore body and the conversion of open-pit mine to underground will be further described.

[0033] attached Figures 1 to 4 Middle: Transitional underground mining area 1, isolated ore pillar between the transitional open-pit mining area and underground mining area 2, transitional open-pit mining area 3, hanging wall mine 4, the first mining section of the deep ore body 5, The second segment of the deep ore body 6, the waste rock covering layer 7, the covering layer 8 during mining of the isolated ore pillar, the goaf 9 mined by the open field method of the upper wall hanging side ore, and the auxiliary ramp 10.

[0034] According to the ore body occurrence conditions, the ore body mining area in the transitional period is divided into transitional open-pit mining area 3, transitional underground mining area 1, isolated ore pillars between open-pit mining and under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com