Coating device

A coating device and plating solution technology, which is applied to the surface coating liquid device, sputter plating, ion implantation plating, etc., can solve the problems of low space utilization, many processes, inconvenient operation, etc., and improve the quality , prevent mutual interference, and increase the effect of coating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

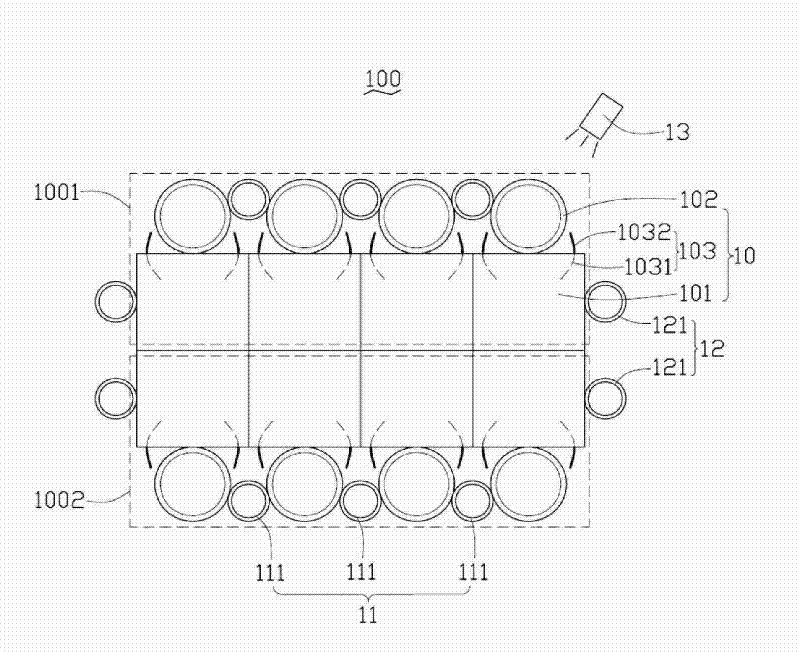

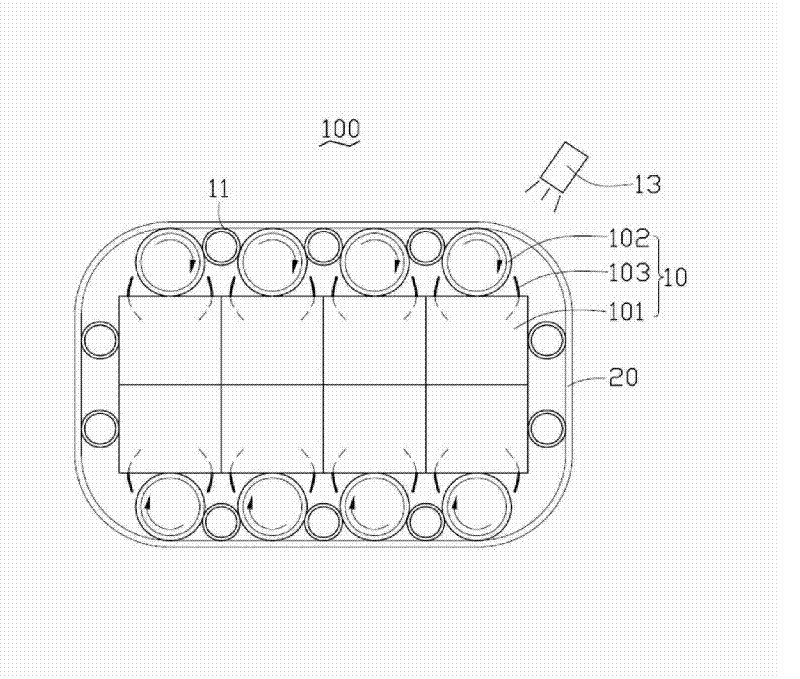

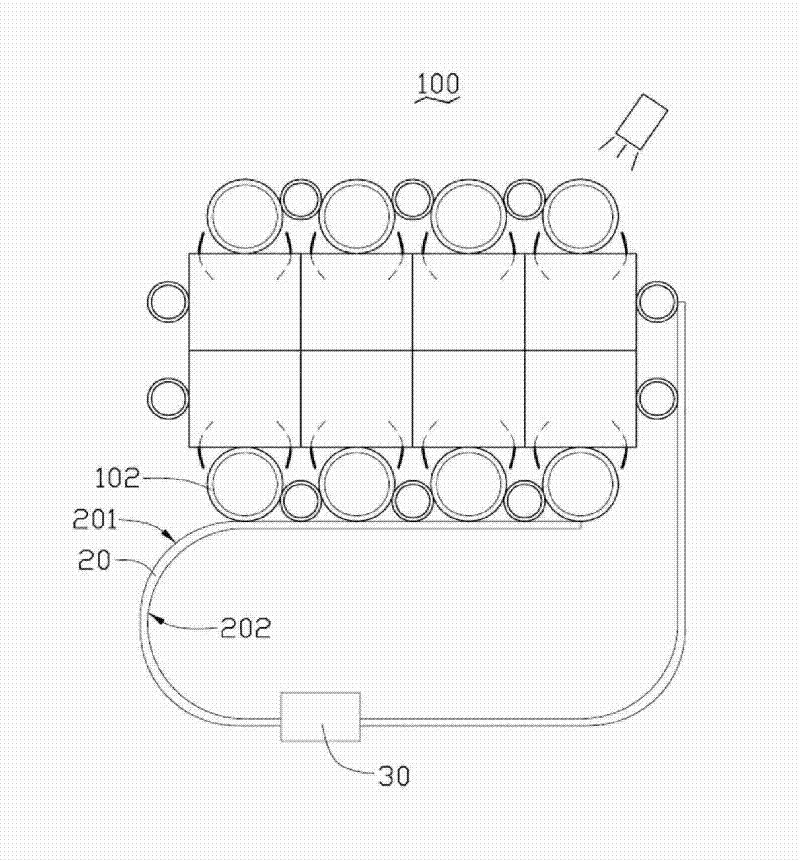

[0013] See figure 1 , the coating device 100 provided by the first embodiment of the present invention includes a plurality of coating solution units 10 and a heating module 11 .

[0014] Each plating solution unit 10 includes a plating solution tank 101 for accommodating the plating solution, a first plating solution drum 102 adjacent to the plating solution tank 101 and a plurality of first spraying liquid modules 103 .

[0015] Each first liquid spray module 103 has a liquid suction end 1031 and a liquid spray end 1032, the liquid suction end 1031 is immersed in the plating solution tank 101, and the liquid spray end 1032 is opposite to the first plating solution cylinder 102. Spray the solution to be plated on it. Preferably, the material of the first plating solution cylinder 102 is alumina, ceramics or stainless steel. Certainly, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com