Ore rock similar material for model test for transferring open pit mining into underground mining

An open-pit-to-underground technology with similar materials is applied in the field of experimental models that take into account the similar materials of the ore body and the surrounding rock mass and fault simulation materials. Complicated and other issues, to achieve the effect of short maintenance period, simple production process and good gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The ore body in this embodiment and the similar materials of the upper and lower surrounding rock masses are composed of the following components:

[0036]

[0037] The preparation method of similar materials of the ore body and the surrounding rock mass is as follows: 1. Weigh the main aggregate according to the above ratio and mix it fully in the cement mortar mixer; 2. Add cementing materials and additives in sequence, and continue stirring for 3-5 Minutes; 3. Pour the mixed material into the steel mold and compact it into shape; 4. Remove the mold, put the prepared model into the oven, and maintain it at a constant temperature of about 30 degrees for 7 days.

[0038] The ore body obtained in this example and the similar materials of the upper and lower surrounding rock masses can reach a maximum density of 2.84 g / cm 3 , suitable for simulating marble. The uniaxial compressive stress-strain curves of the ore body and the similar materials of the upper and lower s...

Embodiment 2

[0045] The ore body in this embodiment and the similar materials of the upper and lower surrounding rock masses are composed of the following components:

[0046]

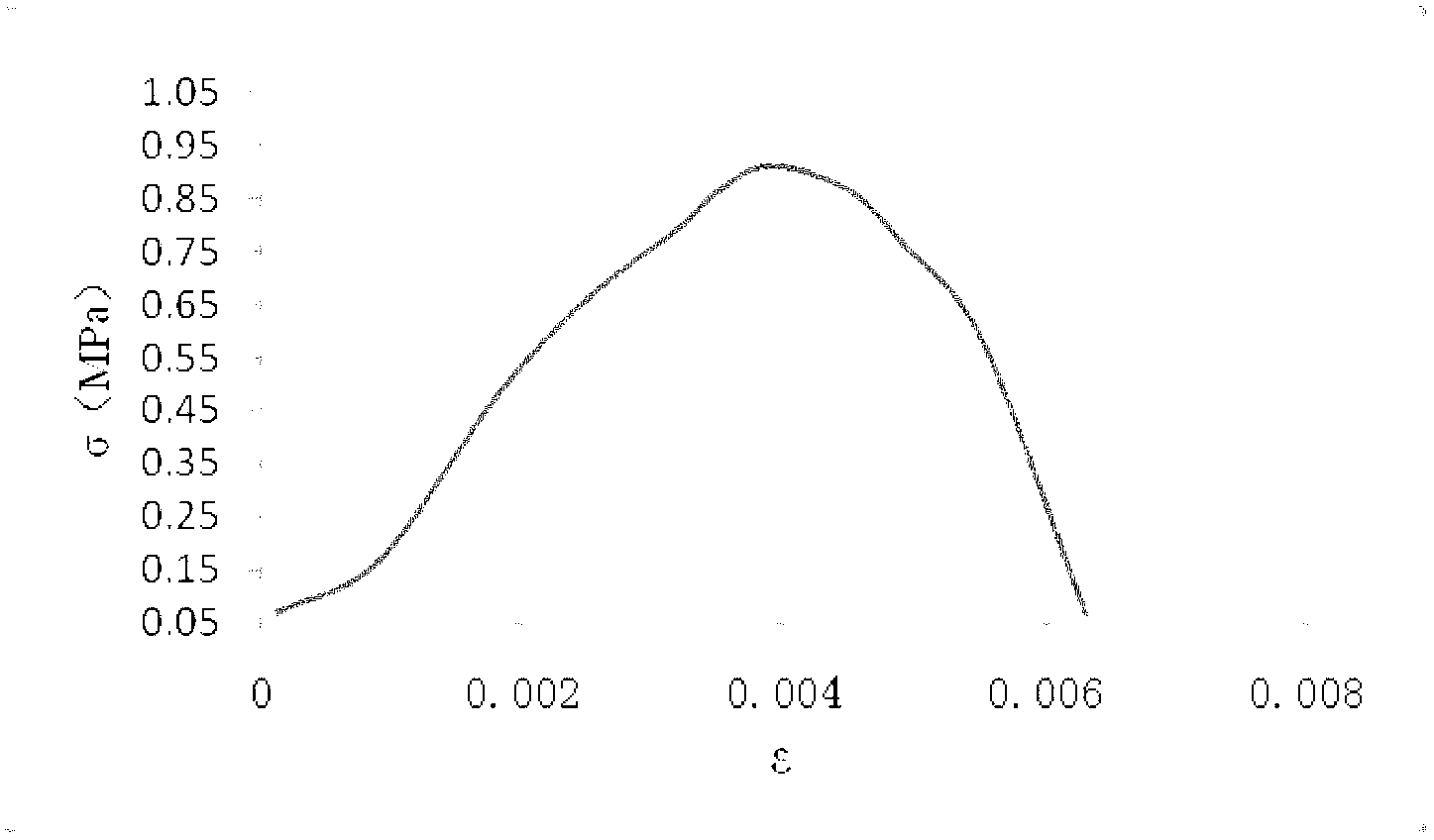

[0047] In this embodiment, the preparation method of similar materials for the ore body and the upper and lower surrounding rock masses is consistent with that in Embodiment 1. The ore body prepared in this embodiment and the similar materials of the upper and lower surrounding rock bodies are suitable for simulating marble. The uniaxial compressive stress-strain curves of the ore body and the similar materials of the upper and lower surrounding rock masses obtained in this embodiment are as follows: figure 2 As shown, its compressive strength and elastic modulus can reach up to 0.91 Mpa and 186Mpa.

[0048] The fault simulating material is a polypropylene film, and the fault simulating material is prepared according to the same method as in Example 1. In this embodiment, the ratio of water to white latex is ...

Embodiment 3

[0050] The ore body in this embodiment and the similar materials of the upper and lower surrounding rock masses are composed of the following components:

[0051]

[0052]

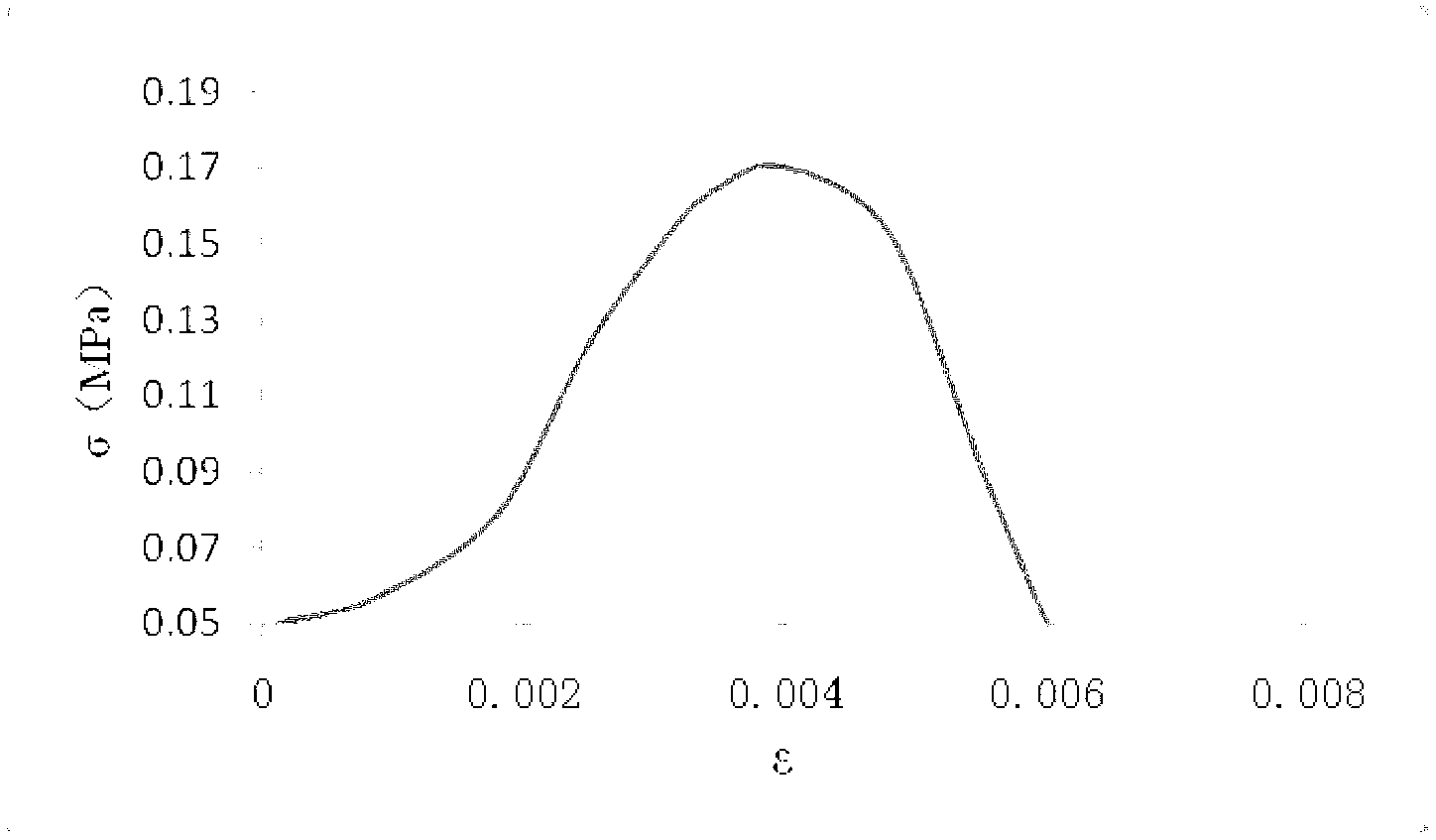

[0053]In this embodiment, the preparation method of similar materials for the ore body and the upper and lower surrounding rock masses is consistent with that in Embodiment 1. The ore body obtained in this example and the similar material density of the upper and lower surrounding rock masses are 2.84 g / cm 3 , suitable for simulating marble. The uniaxial compressive stress-strain curves of the ore body and the similar materials of the upper and lower surrounding rock masses obtained in this embodiment are as follows: image 3 As shown, its compressive strength and elastic modulus can reach up to 0.19 Mpa and 54.1Mpa.

[0054] The fault simulating material is a polypropylene film, and the fault simulating material is prepared according to the same method as in Example 1. In this embodiment, the rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com