Mining method of nearly horizontal mineral deposit of opencast coal field by casting and internally dumping

A mining method and open-pit mining technology, which is applied in the field of open-pit coalfield near-horizontal ore deposits in the mining field of upside-down piles and internal discharges, can solve the problems of occupying cultivated land, increasing the distance of stripped objects, and increasing costs, so as to reduce the distance between internal discharges and save transportation cost, environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

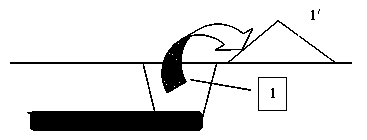

[0023] Example 1 : If the thickness of the overburden of the ore deposit is not large, its thickness is generally less than 50 meters, and the thickness of the ore body is not large, the mining method of direct dumping and internal drainage without transportation can be adopted, that is, the mining and transportation operations are completed by the same equipment.

[0024] Mining equipment can be single bucket excavator, or bulldozer, scraper, front loader, mechanical shovel or dragline. , the stripping material in the second area is discharged in the goaf of the first area, and the mined minerals are transported out of the stope through the transportation channels located on both sides or in the middle of the ditch. Peel off the steps into one step.

[0025] When the thickness of the overburden of the ore deposit is relatively thin, generally between 20m and 50m, use bulldozers, scrapers, front-loading equipment, or single-bucket excavators to open the first ditch by horizo...

Embodiment 2

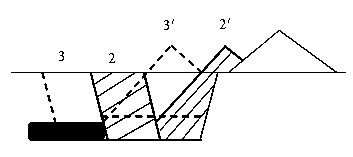

[0027] Example 2 : When the thickness of the overburden layer of the ore deposit is relatively large, the general layer thickness is >50~80m, and the part of the stripped material that exceeds the height of the step height of the non-transportation dumping and internal drainage mining method is set up to set up stripping steps in advance. The specific method is as follows:

[0028] 1) The advanced stripping steps adopt the mining method of transportation, inversion and internal drainage, that is, the mining and transportation operations are completed by different equipment; the height of the steps is determined according to the specifications of the mining equipment used and the thickness of the overburden layer. Generally, it is one step, or it can be multiple Steps, the stripped objects in the first zone of mining still need to be discarded outside the mining boundary. The advanced stripping steps can use single-bucket excavator-automobile mining process system, single-buc...

Embodiment 3

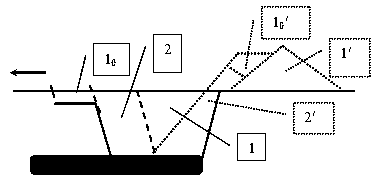

[0030] Example 3: When the thickness of the overburden of the ore deposit is relatively large, the whole mine can also adopt the method of transportation and stacking mining alone, that is, the open-pit mine is divided into several mining steps. According to the equipment used and its specifications, when the bottom stripped After the ore deposit is mined and moved forward to a safe distance, the open-pit mine implements internal dumping from the bottom step, forming the first inner row of steps and reaching the minimum flat width of the dumping step, and establishing the second inner row. Steps, when the second inner row of steps reaches the minimum flat width requirement, the third inner row of steps is established to form the subsequent inner rows of steps until the surface, and the excess stripping materials need to be discharged to the external soil discharge field. When all the inner rows of steps in the stope are formed, the open-pit mine officially enters the stage o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com