Open-pit refined mining method for gently dipping-thin ore body

A mining method and thin ore body technology, applied in the field of open-pit mining, can solve problems such as reducing the loss rate, and achieve the effects of increasing production costs, improving economic benefits, and improving mining efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1: A gentle dip-thin ore body is found in a mine in the south, and the mining steps are as follows:

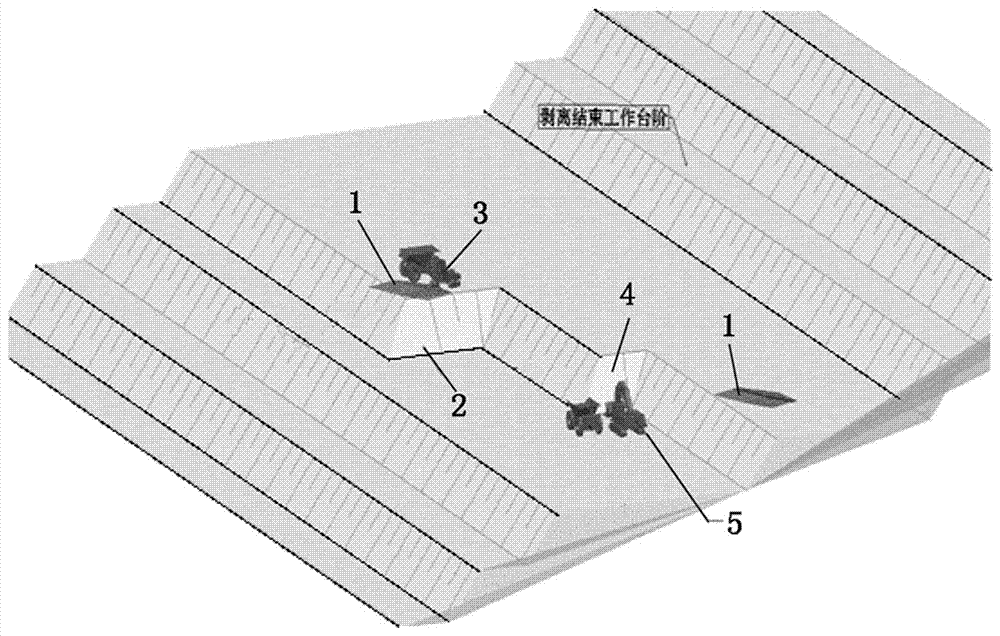

[0044] (1) Exploration to determine the distribution range of the gently inclined-thin ore body (1);

[0045] (2) Make a plan for mining and stripping, determine the scope of mining, and start mining;

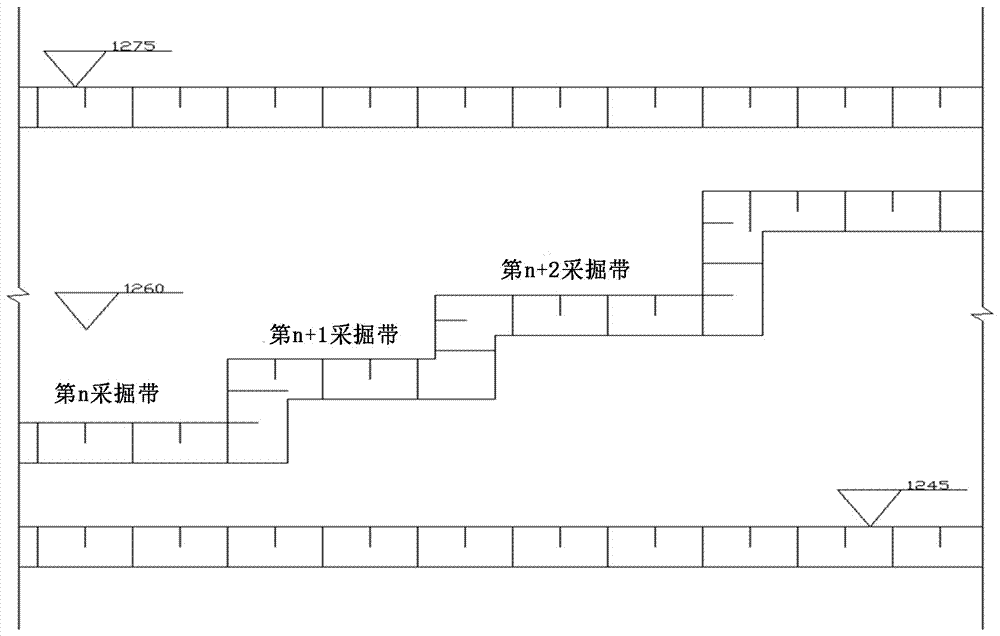

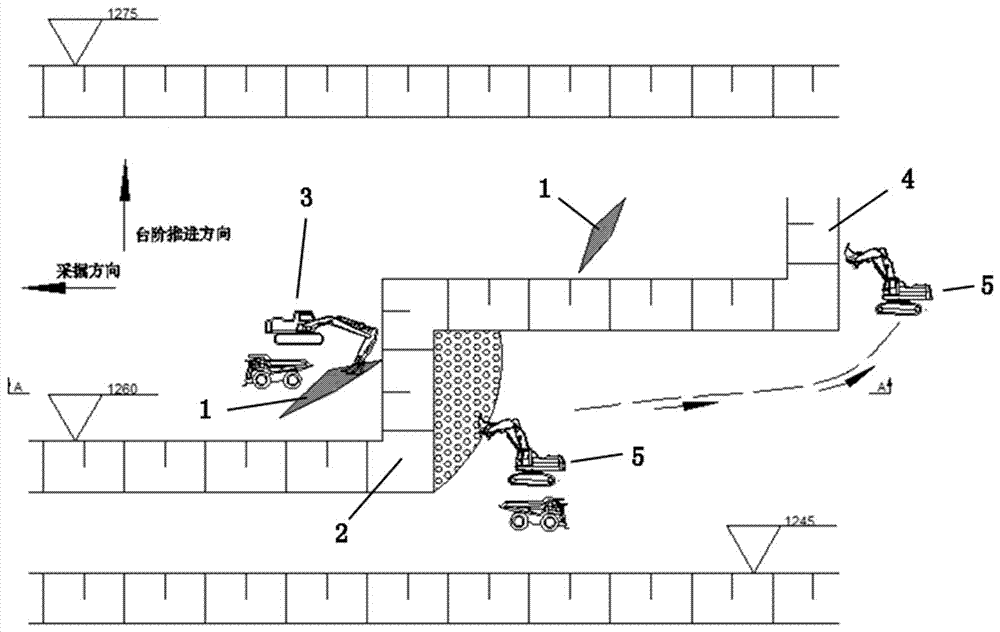

[0046] (3) Use the traditional open-pit mining stripping method to strip the waste soil in the steps without the gently inclined-thin ore body (1), and gradually lower the mining platform. When the mining platform falls to the platform where the gently inclined-thin ore body (1) is located , to calculate the width of the bench entity mining zone A=f(Rwf+Rxm)-c-h / tanα;

[0047] in:

[0048] f=0.85m;

[0049]Rwf=12.2m;

[0050] Rxm=13.7m;

[0051] c=2.5m;

[0052] h=15m;

[0053] α=60°;

[0054] Calculated by the formula, the width of the mining zone is A=11 meters, and the mining area is divided into 6 mining zones;

[0055] (4) Sequentially select two...

Embodiment 2

[0057] Example 2:. A gently inclined-thin ore body was found in a mine in the south. The mining steps are as follows:

[0058] (1) Exploration to determine the distribution range of the gently inclined-thin ore body (1);

[0059] (2) Make a plan for mining and stripping, determine the scope of mining, and start mining;

[0060] (3) Use the traditional open-pit mining stripping method to strip the waste soil in the steps without the gently inclined-thin ore body (1), and gradually lower the mining platform. When the mining platform falls to the platform where the gently inclined-thin ore body (1) is located , to calculate the width of the bench entity mining zone A=f(Rwf+Rxm)-c-h / tanα;

[0061] in:

[0062] f=0.85m;

[0063] Rwf=12.0m;

[0064] Rxm=12.4m;

[0065] c=2.5m;

[0066] h=10m;

[0067] α=60°;

[0068] Calculated by the formula, the width of the mining zone is A=12 meters, and the mining area is divided into 6 mining zones;

[0069] (4) Sequentially select t...

Embodiment 3

[0071] Embodiment 3: A gentle dip-thin ore body is found in a mine in the south, and the mining steps are as follows:

[0072] (1) Exploration to determine the distribution range of the gently inclined-thin ore body (1);

[0073] (2) Make a plan for mining and stripping, determine the scope of mining, and start mining;

[0074] (3) Use the traditional open-pit mining stripping method to strip the waste soil in the steps without the gently inclined-thin ore body (1), and gradually lower the mining platform. When the mining platform falls to the platform where the gently inclined-thin ore body (1) is located , to calculate the width of the bench entity mining zone A=f(Rwf+Rxm)-c-h / tanα;

[0075] in:

[0076] f=0.9m;

[0077] Rwf=13.1m;

[0078] Rxm=13.5m;

[0079] c=2.0m;

[0080] h=10m;

[0081] α=60°;

[0082] Calculated by the formula, the width of the mining zone is A=17 meters, and the mining area is divided into 4 mining zones;

[0083] (4) Sequentially select two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com