Mechanized mining method through downward or upward cemented filling for steeply-inclined orebody with extremely-crushed ore rock

A technology of cemented filling and mining methods, applied in underground mining, filling, surface mining, etc., can solve the problems of high mining cost, easy collapse, loss, etc., achieve low ore loss and dilution rate, easy to combine exploration and mining, The effect of reducing blast damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

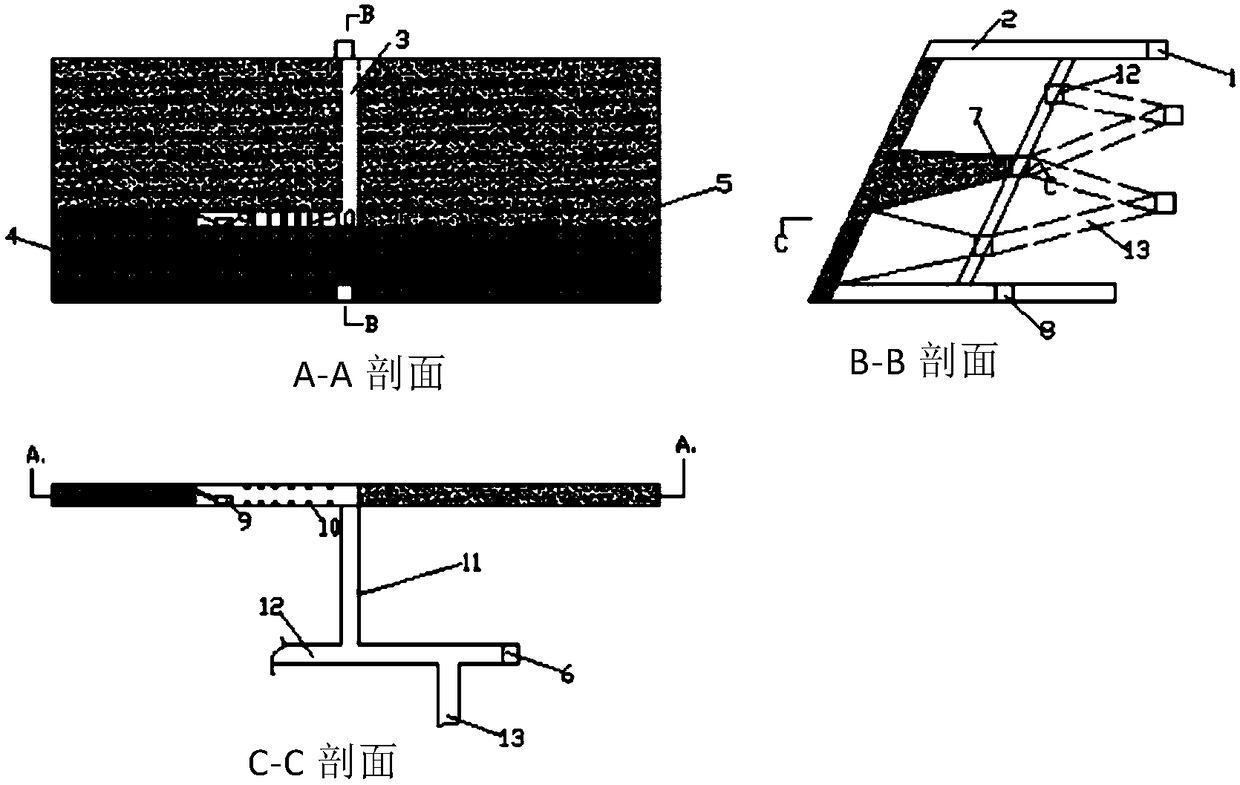

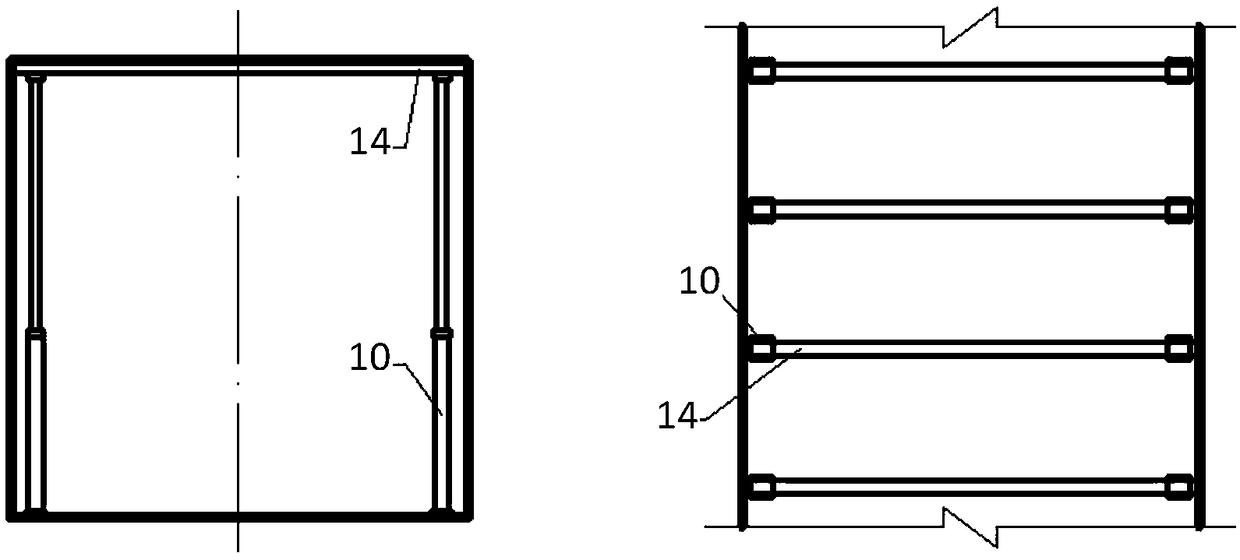

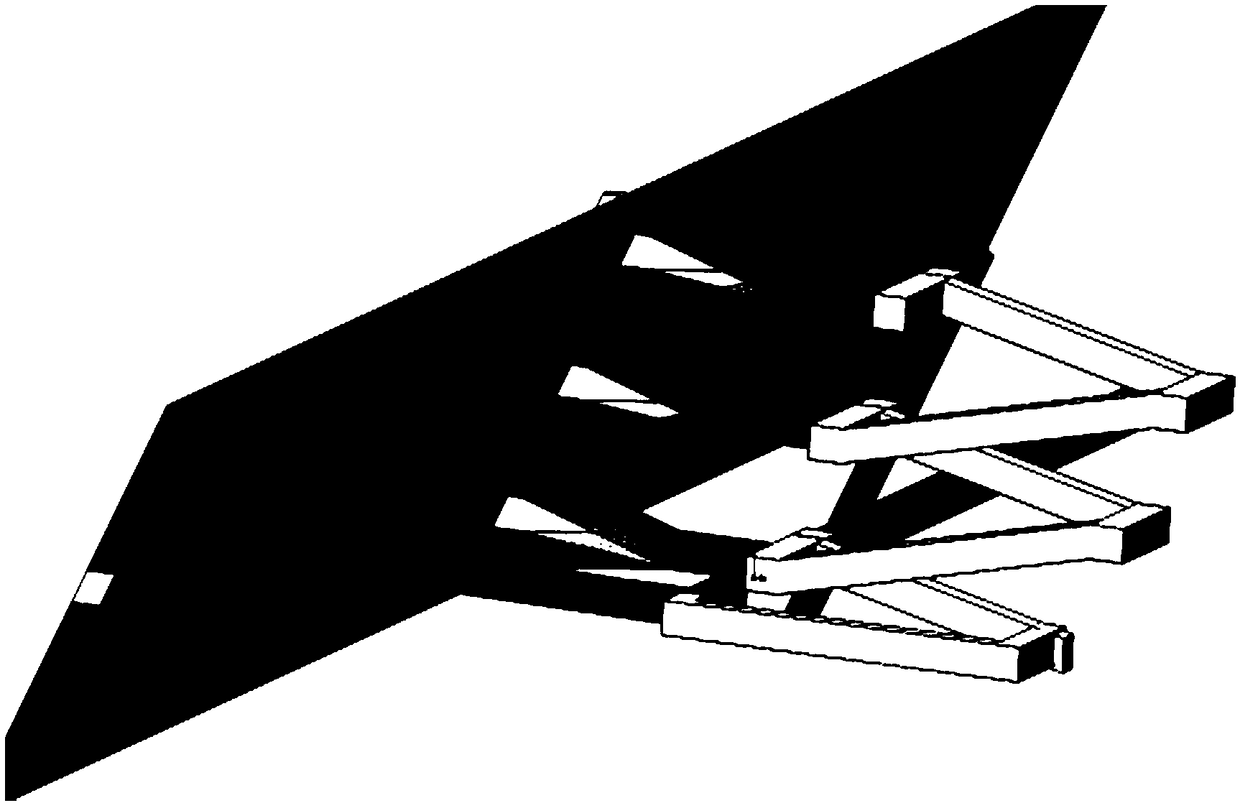

[0022] refer to figure 1 , This mining method is suitable for mining steeply inclined high-grade ore bodies where the ore and surrounding rock are not stable or only the ore is not stable. The method is: mining from the top-down layered approach, or bottom-up layered approach mining; after excavating the layered connecting road, enter the ore body along the layered connecting road, and use the cantilever roadheader instead of blasting In the mine, each layer is arranged along the strike (thin ore body) or vertically (thick and large ore body) at the full height, and the ore is dropped in intervals or in sequence and the forklift is out of the mine. The whole layer is mined in one or two steps. After the filling is completed, transfer to the next layer, and recover downwards under the top plate of the filling body, or recover upwards on the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com