High-sublevel subdivision mining method of moderately thick heavy-pitch waste-rock-containing interlayer phosphate orebody along strike

A technology of steep slope and mining method, applied in the field of mine mining, can solve the problems of excessive mining ratio, low production efficiency, and large resource loss, and achieve the effect of small mining ratio, high production efficiency, and small environmental damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

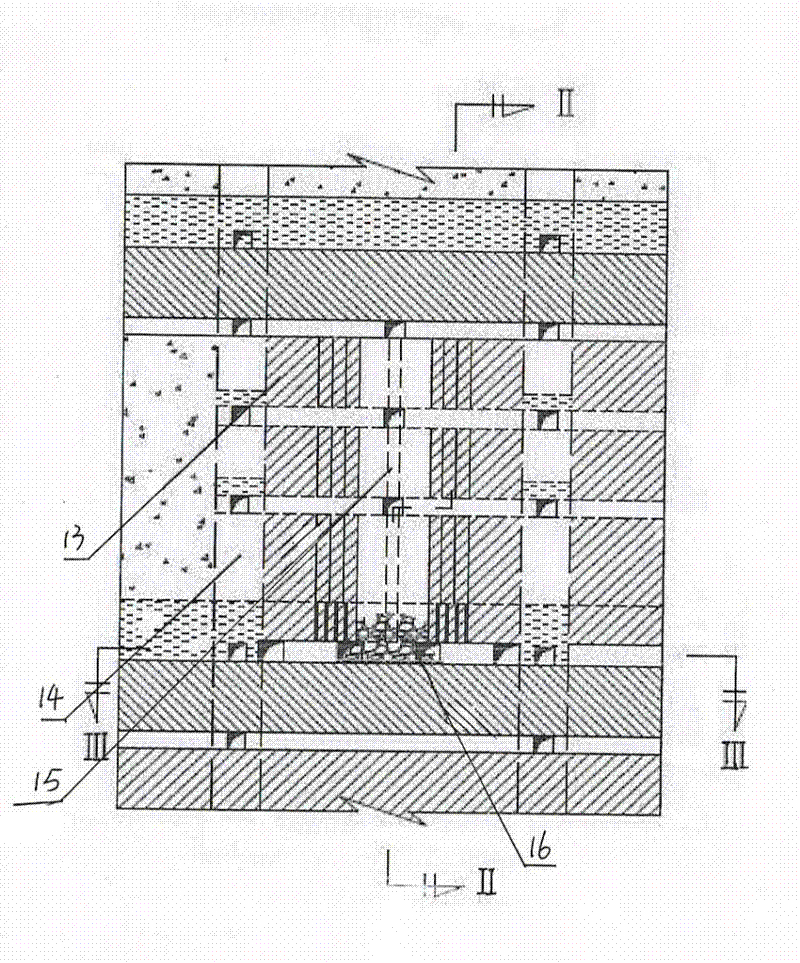

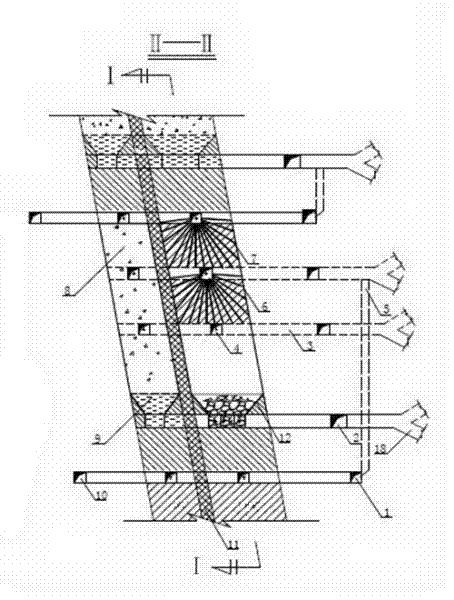

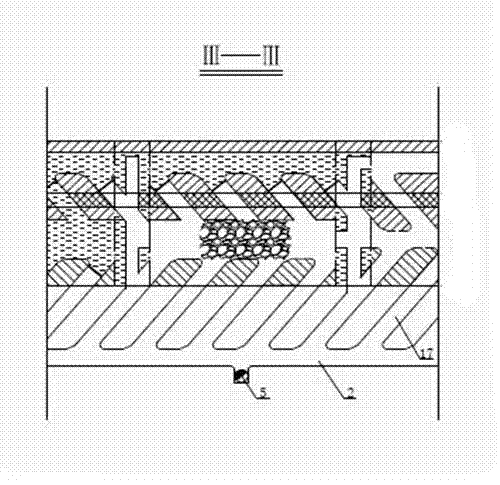

[0022] Example: Datang Mine (line 8+30-6+240) is an example of the mining method of the medium-thick and steeply inclined phosphate ore body containing waste rock interlayer along the strike high segmental mining method.

[0023] The ore body mined by Datang Mine is a marine sedimentary phosphate deposit, and the Datang ore section is a large phosphate rock deposit with flat ore body boundary, simple structure, small structural damage, and small thickness variation. The Datang mine section is located in the middle section of the east wing of the Baiyan anticline, and the occurrence of the ore seam is basically the same as that of the rock formation, which is layered, monocline, and steeply dipped. The ore body strikes at about 27° to the northeast, and the inclination is restricted by the broad and gentle axis of the Baiyan anticline and the sharp steepening of the east wing. The industrial phosphate rock layer in the mining area is divided into two layers, that is, a-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com