Large-scale horizontal jamb mining method under existence of bottom caving group occurrence

A mining method and ore pillar technology, applied in underground mining, surface mining, special mining, etc., can solve problems such as long mining operation time and large amount of horizontal ore pillar resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation plan

[0018] Below in conjunction with accompanying drawing in conjunction with example the use of the present invention will be further described :

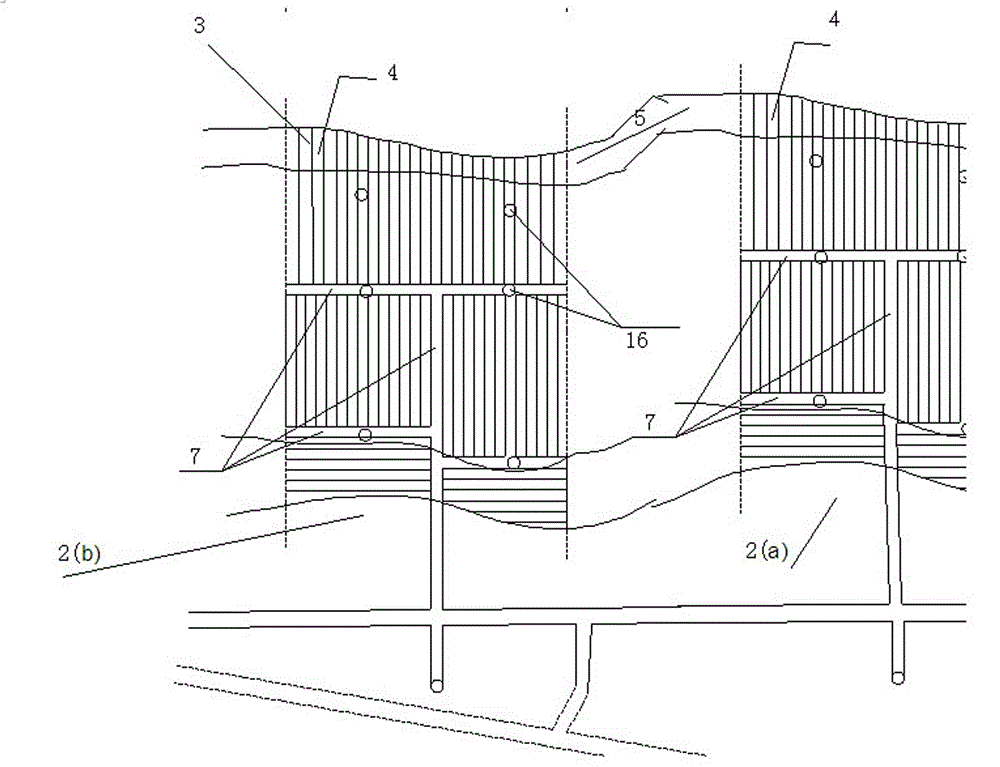

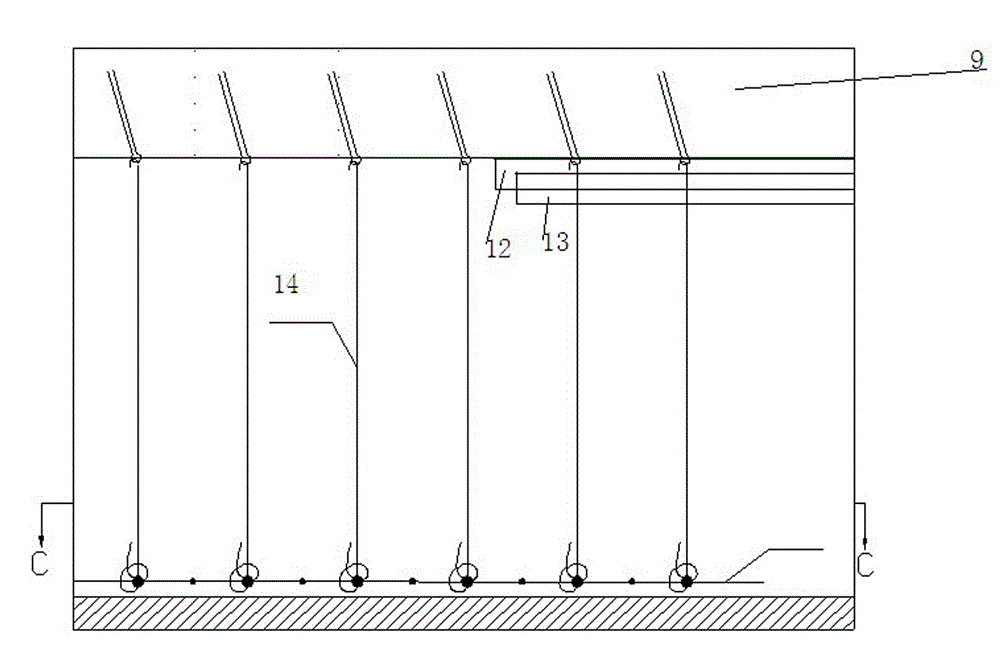

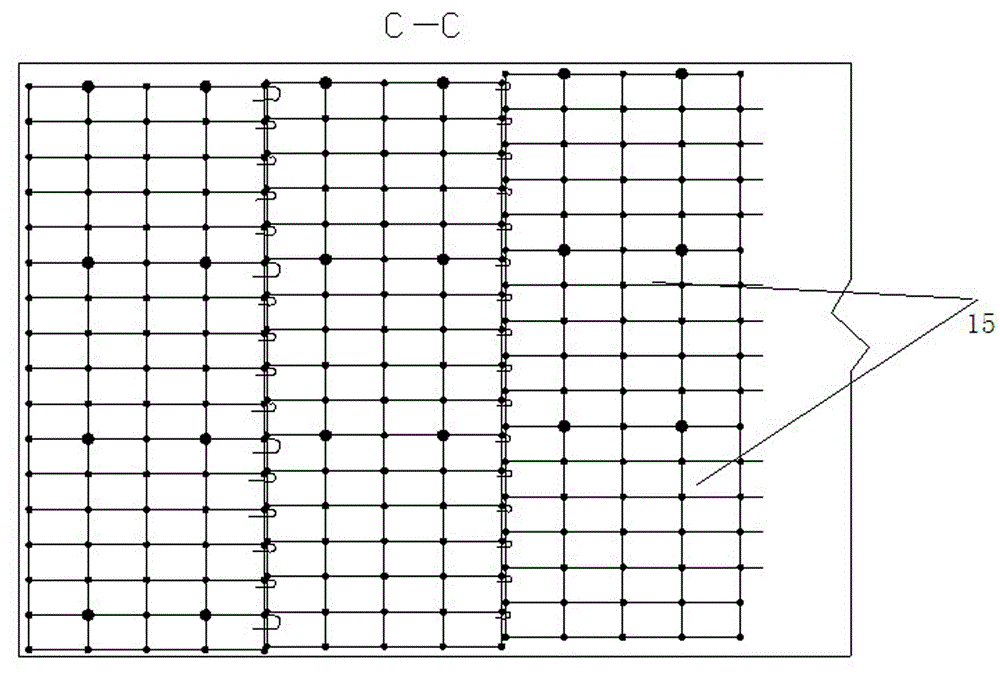

[0019] 1. The mining plan and mining organization adopting step-wise advancement: Assuming that a super-large-scale caving group with a length of about 600 m and an average thickness of about 120 m is planned to be a horizontal pillar 1, the height of 4.8 m can be first Divide into several layers 8, and then divide each layer into several panels according to 100m×100m, mark the odd-numbered panels and double-numbered panels in sequence according to the ore body trend, and divide each panel into 5m wide×4.8m high The first mining route of each panel is called ore room 3, and the later mining route is called ore pillar 4; the mining room 3 of the double-numbered panel is mined first, and the ore pillar 4 of the single-numbered panel is mined later ,vice versa.

[0020] 2. When affected by ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com