Novel technique of slight-pitch ore body overall mining method

A kind of gently inclined, mining method technology, applied in the direction of surface mining, underground mining, special mining, etc., can solve the problem of affecting the mining capacity, etc., to reduce the reserved natural ore pillars, reduce the loss rate and dilution rate, improve the recovery rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Taking a 425-meter middle section 9# gold mine stope as the stope object of this embodiment, the specific mining operation steps are as follows:

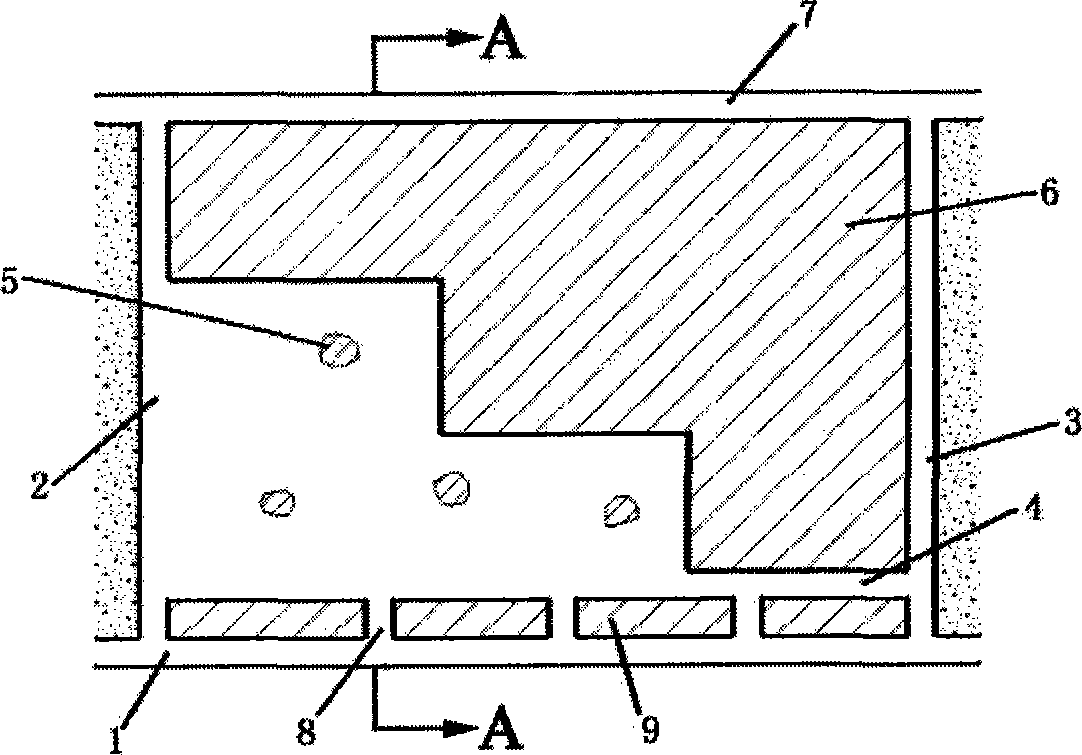

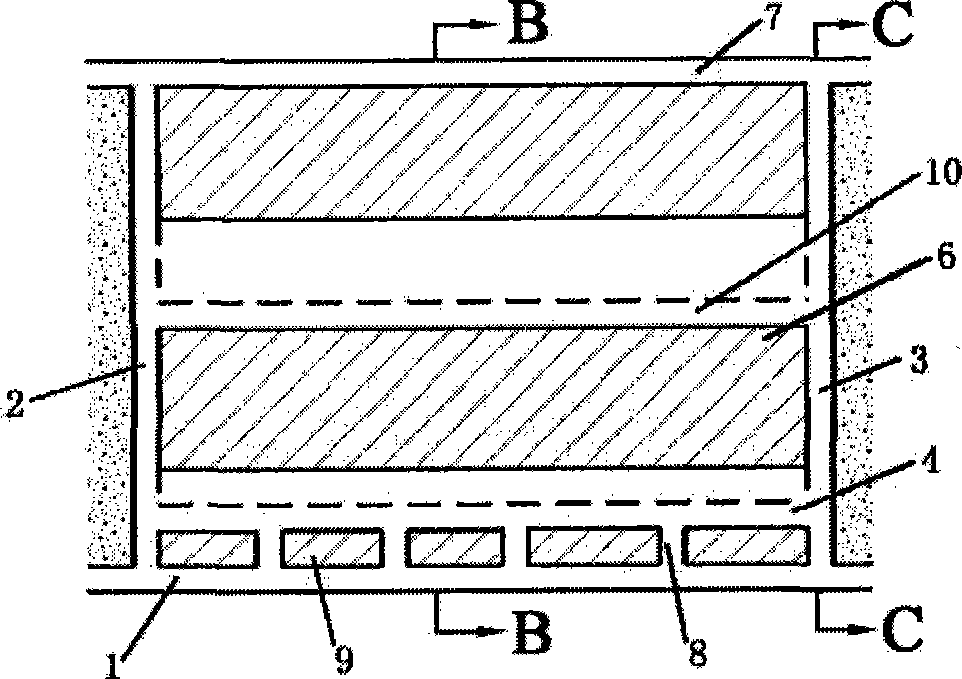

[0018] (1) Nugget layout and constituent elements

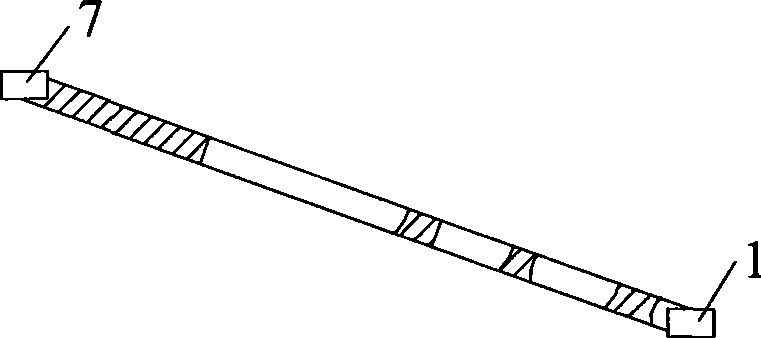

[0019] like image 3 As shown, the 425m lower middle section 1 along the vein roadway exposes the ore body 6 with a strike length of 39m, the average thickness of the ore body 6 is 2.80m, the average inclination angle α of the ore body 6 is 28°, the 425m lower middle section 1 and the 450m 450m upper middle section 7 The inclined length of the stage is 53 meters, the bottom pillar is 9 meters thick and 3 meters thick. The reserved natural ore pillars are flexibly reserved according to the grade of the ore body and the firmness of the roof.

[0020] (2) Adopt quasi-cutting work

[0021] In the ore body 6 exposed by the level road in the first stage of the lower and middle section of 425 meters, the tunnel 3 is connected with the pedestrians 2 and the upper and middle sectio...

Embodiment 2

[0028] Taking a 450-meter middle section 3# gold mine stope as the stope object of this embodiment, the specific mining operation steps are as follows:

[0029] (1) Nugget layout and constituent elements

[0030] like image 3 As shown, the 450-meter lower middle section 3 along the vein roadway exposes the ore body 6 with a strike length of 53 meters, the average thickness of the ore body 6 is 2.90 meters, and the average inclination angle α of the ore body 6 is 27°. The oblique length of the stage is 55 meters, the bottom pillar is 9 meters thick and 3 meters thick. The reserved natural ore pillars are flexibly reserved according to the grade of the ore body and the firmness of the roof.

[0031] (2) Adopt quasi-cutting work

[0032] In the ore body 6 exposed by the level road in the first stage of the 450-meter lower and middle section, the tunnel 3 is connected to the pedestrians 2 and the 475-meter upper and middle section 7 to form a return air and pedestrian safety sy...

Embodiment 3

[0037] Taking the 5# gold mine stope in the middle section of a 575 as the stope object of this embodiment, the specific mining operation steps are as follows:

[0038] (1) Nugget layout and constituent elements

[0039] like image 3 As shown, the 575-meter lower middle section 3 exposes the ore body 6 along the vein roadway with a strike length of 60 meters, the average thickness of the ore body 6 is 2.75 meters, and the average inclination angle α of the ore body 6 is 29°. The sloping length of the stage is 52 meters, the bottom pillar is 9 meters thick and 3 meters thick. The reserved natural ore pillars are flexibly reserved according to the grade of the ore body and the firmness of the roof.

[0040] (2) Adopt quasi-cutting work

[0041]In the ore body 6 exposed in the first stage of the 575-meter lower and middle section, the excavation and cutting uphill 3 connects with the pedestrian uphill 2 and the 600-meter upper middle section 7 to form a return air and pedestri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com