Method for recycling ore pillars by middle-deep hole and deep hole united blasting technique

A deep hole and pillar technology, applied in blasting, ground mining, earthwork drilling and mining, etc., can solve the problems of hidden safety hazards, low recovery rate, large loss index, etc., achieve less engineering investment, lower dilution rate, highly operable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

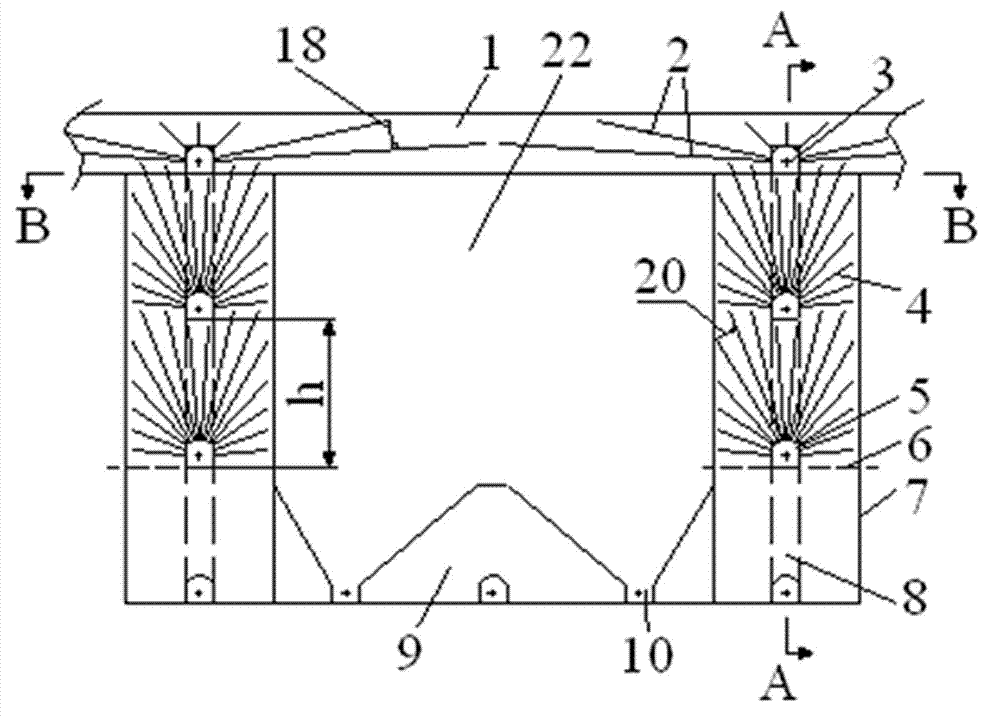

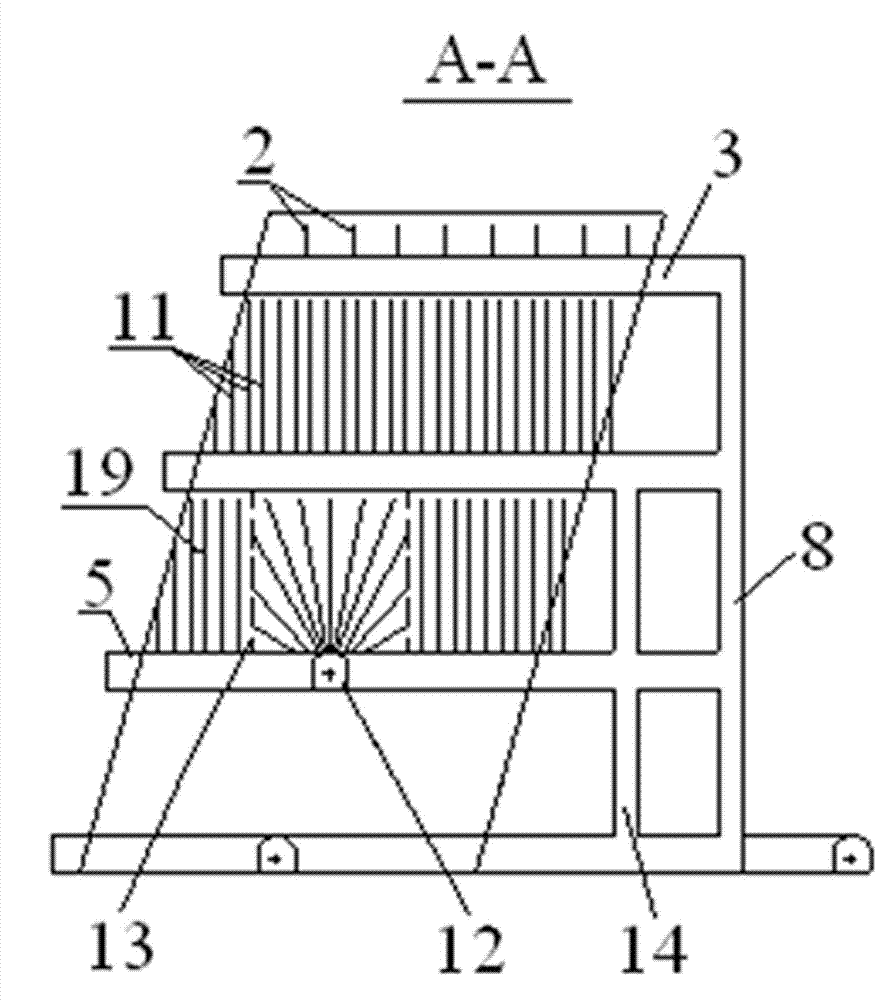

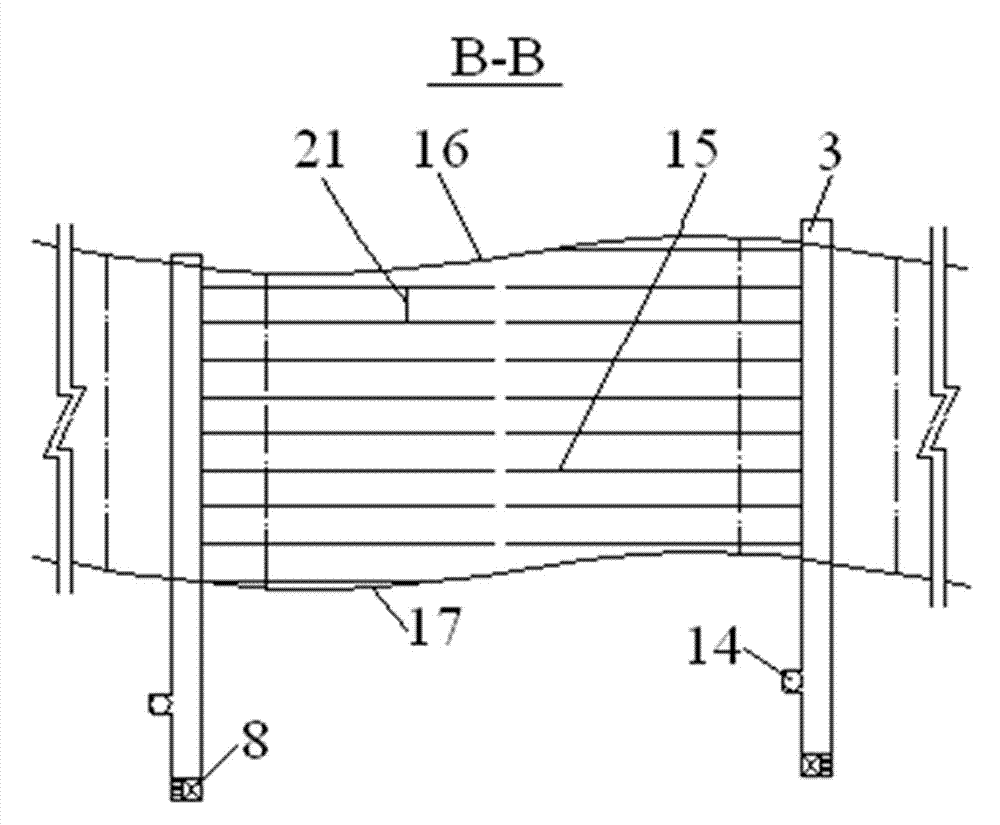

[0064] Through the ventilated pedestrian patio outside the vein, multiple blasting layers are sequentially divided on the inter-column of the mined-out mine room along the height direction of the inter-column, and the distance h between the upper and lower adjacent two blasting sub-layers is 14m; Arrange medium and deep hole rock drilling roadways whose axis is perpendicular to the axis of the ventilation pedestrian patio on each blasting layer, and the medium and deep hole rock drilling roadways are located on the bottom surface of the corresponding blasting layer; × 2.8m three-core arch; multiple rows of medium-deep hole blasthole groups are arranged side by side on the wall of the medium-deep hole rock drilling roadway, and the distance between two adjacent medium-deep hole blasthole groups is 1.2m; each medium-depth The blasthole group is composed of multiple medium-deep hole blastholes. All the medium-deep hole blastholes in a medium-deep hole blasthole group form a fan wi...

Embodiment 2

[0070] Through the ventilated pedestrian patio outside the vein, multiple blasting layers are sequentially divided along the height direction of the spacer column with a width of more than 15m in the mined mine house, and the distance between two adjacent blasting layers 12m, on each blasting layer, arrange two medium-deep hole rock drilling roadways whose axes are perpendicular to the axis of the ventilation pedestrian patio, and the two medium-deep hole rock drilling roadways are located on the bottom surface of the corresponding blasting layer; The two middle and deep hole rock drilling roadways in the blasting layer divide the spacer column into three parts equally. Multiple rows of medium-deep hole blasthole groups are arranged side by side on the top, and the distance between two adjacent medium-deep hole blasthole groups is 1.2m; each medium-deep hole blasthole group All the medium-deep hole blastholes in the blasthole group form a fan with the center of the vault cente...

Embodiment 3

[0075] Through the ventilated pedestrian patio outside the vein, multiple blasting layers are sequentially divided on the inter-column of the mined-out mine room along the height direction of the inter-column, and the distance between the upper and lower adjacent two blasting sub-layers is 15m; A medium-deep hole drilling roadway whose axis is perpendicular to the axis of the ventilation pedestrian patio is arranged on each blasting layer, and the medium-deep hole drilling roadway is located on the bottom surface of the corresponding blasting layer; the section of the medium-deep hole rock drilling roadway is 2.8m× 2.8m three-core arch; multiple rows of medium-deep hole blasthole groups are arranged side by side on the wall of the medium-deep hole rock drilling roadway, and the distance between two adjacent medium-deep hole blasthole groups is 1.1m; each medium-deep hole The blasthole group is composed of multiple medium-deep hole blastholes. All the medium-deep hole blastholes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com