Method for exploiting residual crude oil in low-permeability oilfield by using polymer micro/nanoparticle

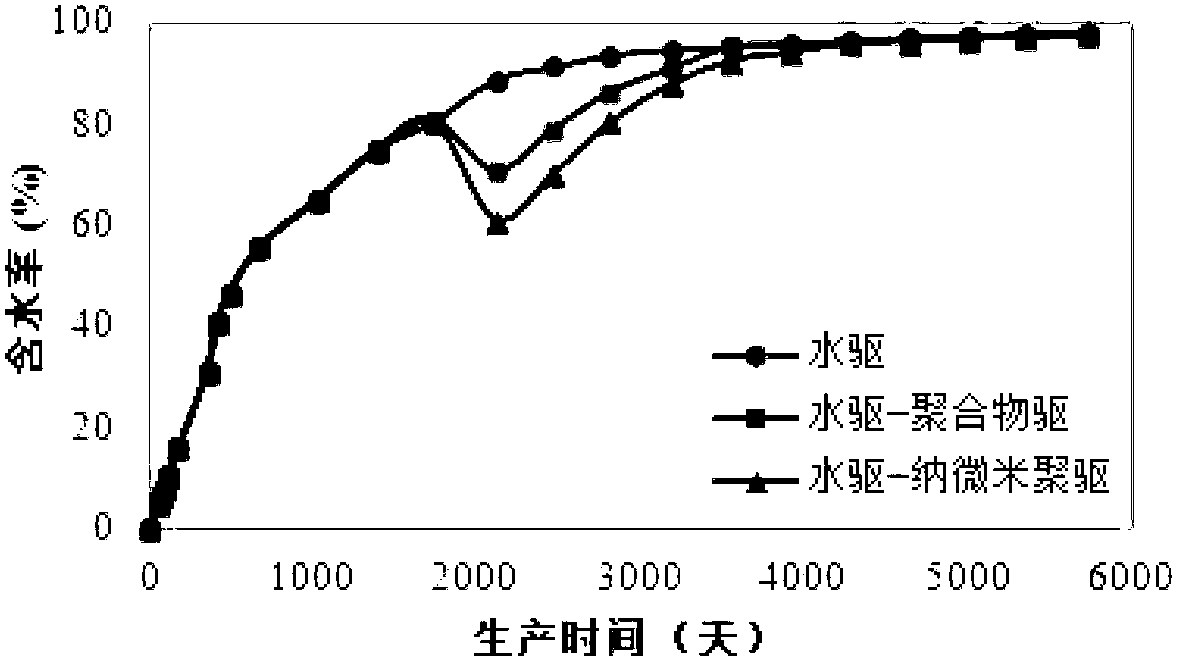

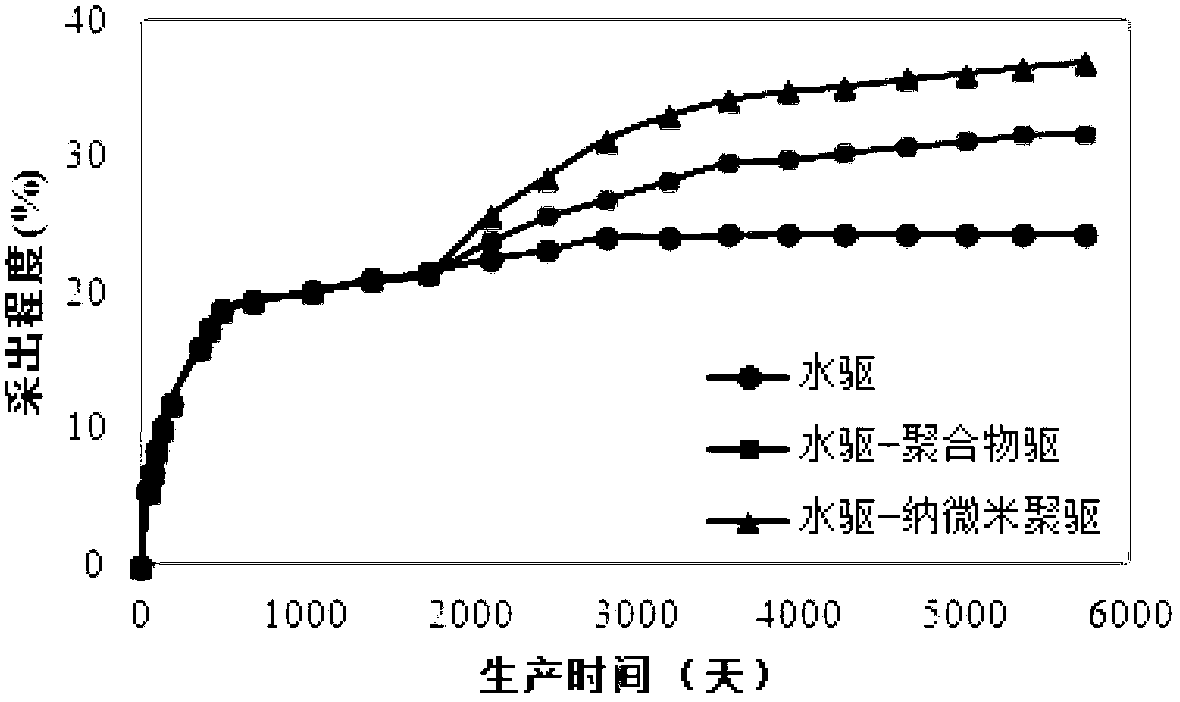

A polymer particle, nano-micron technology, applied in the direction of mining fluids, drilling compositions, chemical instruments and methods, etc., can solve difficult large-scale mining effects, insufficient low-permeability supply capacity, short effective mining time, etc. problems, to achieve the effects of strong oil washing ability, enhanced oil recovery, and strong expansion of the swept volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0035] The South 2nd and 3rd areas of Daqing Oil Production Plant 2 are located at the southern end of the Saertu anticline structure. The dip angle of the strata is 10° on the west side and 3.5° on the east side; It is deposited at the outer front of the delta, and its lithology is mainly composed of fine sandstone, fine siltstone and argillaceous siltstone, containing a small amount of mixed layers of illite and smectite, with low expansibility and high chlorite content. The lithology of the surface and inner layer is mainly fine and siltstone, with an average air permeability of 22.5mD, an average porosity of 27.12%, and an average original oil saturation of 62.37%.

[0036] According to the principles and standards of well selection, the water wells in the Gaotaizi oil layer area in the second and third areas of the South were analyzed. -51, High 167-51, High 169-53, and High 170-53 are composed of 8 water wells. There are 21 oil wells in the well area and 6 central produc...

Embodiment 1

[0053] Take 1 mol of acrylamide and 10 mol of acrylic acid, put them into the single-necked round bottom flask 1 (reaction vessel), add 35.6 mol of acetonitrile solvent into the bottle, mix well, and ultrasonically disperse them, then add 0.1 mol of N-N Methylenebisacrylamide (MBAA), adding 0.02mol of azobisisobutyronitrile (AIBN) is also ultrasonically dispersed; (2) The round bottom flask containing the reaction solution 2 is placed in an oil bath (heating device 6) , tilt downward at a certain angle, such as 30°, and install the condensing return pipe 3, the condensing joint 4 and the receiving container 5; (3) The oil bath starts to heat up, and rises from normal temperature to boiling within 15 minutes. Keep it at about 90°C for 15 minutes; (4) Adjust the temperature of the oil bath to 110°C, increase the distillation intensity, and the solvent in the flask will continuously flow into the receiving container. After about 90 minutes, the solvent in the flask Almost all are...

Embodiment 2

[0055] Take 10 mol of acrylamide and 1 mol of 2-acrylamido-methylpropanesulfonic acid (AMPS), add them into a single-necked round bottom flask, add 173 mol of acetonitrile solvent into the bottle, mix well, disperse it by ultrasonic, and put it into the round bottom flask Add 0.1mol of divinylbenzene to the flask, add 0.05mol of azobisisoheptanonitrile and ultrasonically disperse it; Tilt at a certain angle, such as 30°, and install the condensing return pipe, condensing joint and receiving container; (3) The oil bath starts to heat up, and rises from normal temperature to boiling within 18 minutes. The temperature of the oil bath is kept at about 90°C. 15 minutes in this state; (4) Adjust the temperature of the oil bath to 120°C, increase the distillation intensity, and the solvent in the flask will continuously flow into the receiving container. After about 100 minutes, almost all the solvent in the flask will be distilled out. Under the situation that guarantees this distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Permeability | aaaaa | aaaaa |

| Average permeability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com