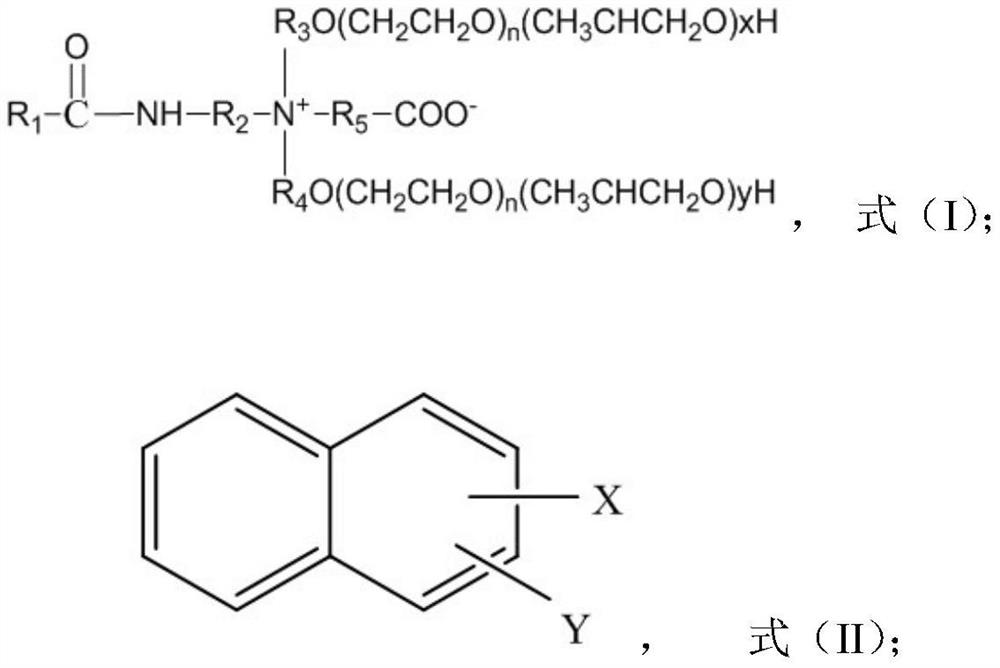

Polyether carboxylate-containing non-alkali viscoelastic surfactant composition, preparation method and use

A technology of surfactant and polyether carboxylate, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of low oil displacement efficiency and achieve high interface activity, simple system and good technical effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

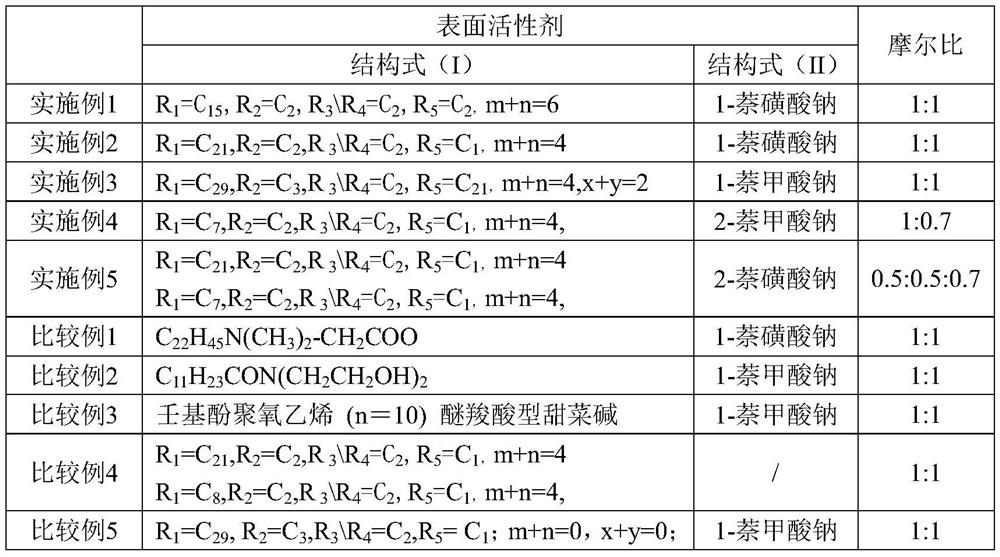

Embodiment 1

[0025] 1. Surfactant Preparation

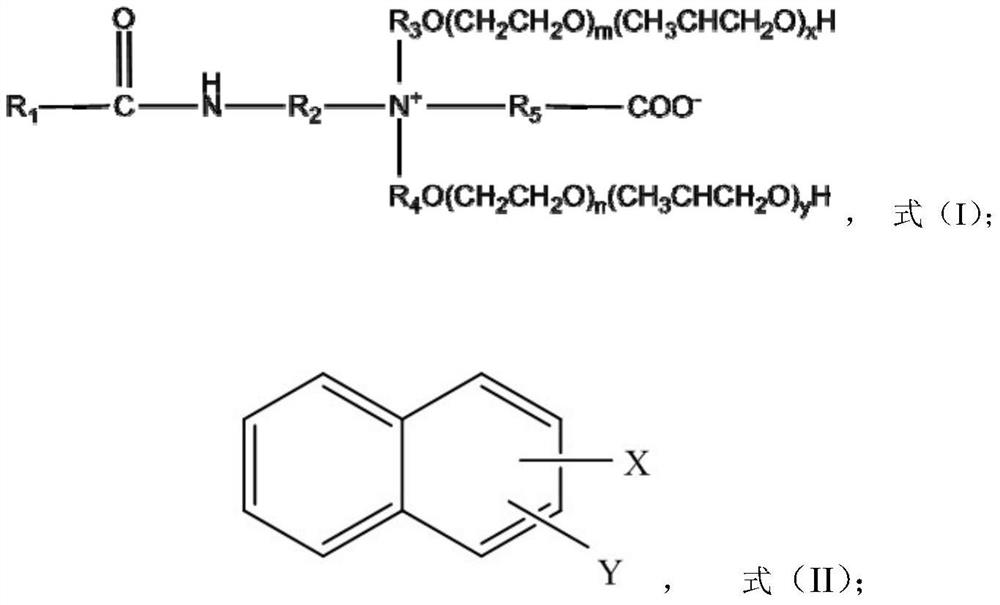

[0026] (1) palmitic acid amide carboxy betaine amphoteric surfactant (R 1 =C 15 , R 2 =C 2 , R 3 \R 4 =C 2 , R 5 =C 2 ) preparation

[0027] a) Add long carbon chain hexadecanoic acid methyl ester and the required amount of amidation reagent N,N-bis(2-hydroxyethyl)ethylenediamine into the reaction kettle, react at 130°C for 6 hours, turn on the vacuum pump, and pump Remove excess N,N-bis(2-hydroxyethyl)ethylenediamine, and then heat to 150°C while passing nitrogen into the reactor equipped with condensing device and stirring device, add ethylene oxide after heating for 40 minutes alkanes (2 moles), the temperature was maintained at 150°C and the reaction was stirred for 1 hour. Cool down to 80°C, add barium hydroxide as a catalyst, heat to 140°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, and then use nitrogen to blow 4 times to remove the air in the system, and then adjust the reaction temperature of the sys...

Embodiment 2

[0037] 1. Surfactant Preparation

[0038] (1) Erucamide carboxy betaine amphoteric surfactant (R 1 =C 21 , R 2 =C 2 , R 3 \R 4 =C 2 , R 5 =C 1 ) preparation

[0039] a) Add methyl erucate and the required amount of amidation reagent N,N-bis(2-hydroxyethyl)ethylenediamine into the reaction kettle, react at 145°C for 7 hours, turn on the vacuum pump, and remove excess N , N-bis(2-hydroxyethyl)ethylenediamine to obtain the erucic acid acyl tertiary amide product, and then heat to 150°C while passing nitrogen into the reactor equipped with a condensation device and a stirring device, after heating for 40 minutes Ethylene oxide (2 moles) was added, and the temperature was maintained at 150° C. and the reaction was stirred for 1 hour. Cool down to 80°C, add barium hydroxide as a catalyst, heat to 140°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, and then use nitrogen to blow 4 times to remove the air in the system, and then adjust the reaction tempe...

Embodiment 3

[0044] 1. Surfactant Preparation

[0045] (1) triacic acid amide carboxy betaine surfactant (R 1 =C 29 , R 2 =C 3 , R 3 \R 4 =C 2 , R 5 =C 2 ) preparation

[0046] a) Add the long carbon chain triacic acid methyl ester and the required amount of amidating reagent N,N-bis(2-hydroxyethyl)propylenediamine into the reaction kettle, react at 150°C for 8 hours, turn on the vacuum pump, and pump Remove excess N,N-bis(2-hydroxyethyl)propylenediamine to obtain triacyl acyl tertiary amine product, and then heat to 150°C while blowing nitrogen into a reactor equipped with a condensing device and a stirring device After heating for 40 minutes, ethylene oxide (2 moles) was added, and the temperature was maintained at 150° C. and stirred for 1 hour. Cool down to 80°C, add barium hydroxide as a catalyst, heat to 140°C, turn on the vacuum system, dehydrate under high vacuum for 1 hour, and then use nitrogen to blow 4 times to remove the air in the system, and then adjust the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com