Alkali-free viscoelastic surfactant as well as preparation method and application thereof

A surfactant and viscoelastic technology, which is applied in the field of preparation of alkali-free viscoelastic surfactants, can solve problems such as injection difficulties and formation blockage, and achieve the effects of reduced repulsion, high interfacial activity, and excellent temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] 1. Surfactant Preparation

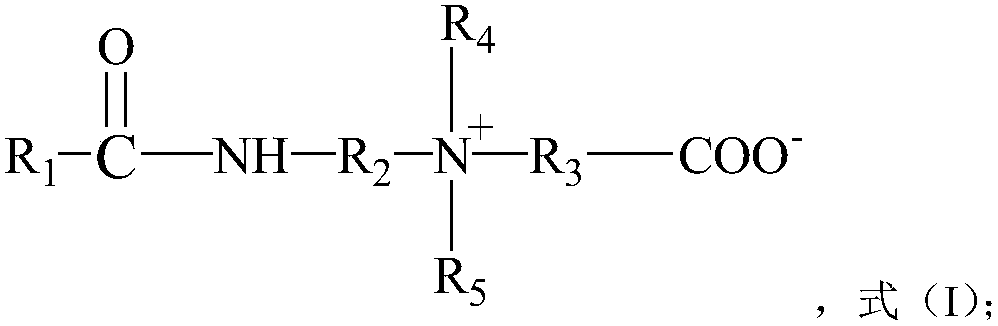

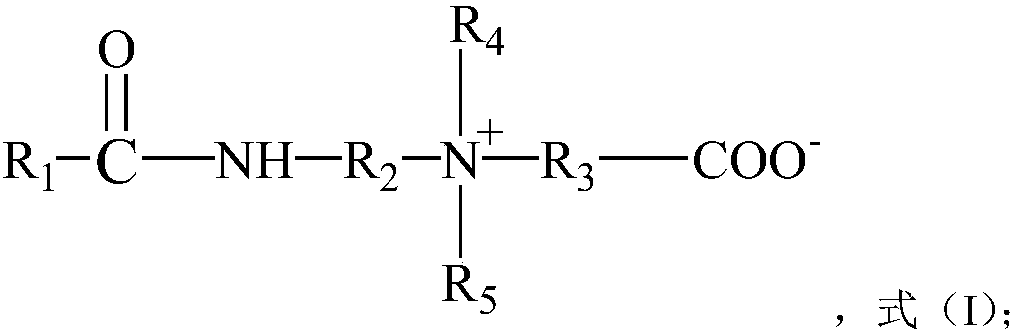

[0033] (1) Erucamide carboxy betaine surfactant (R 1 =C 21 , R 2 =C 3 , R 3 =C 2 , R 4 , R 5 =C 1 ) preparation

[0034] a) Add 0.5 mole of methyl erucate and the required amount of amidating reagent N,N-dimethylpropylenediamine into the reaction kettle, react at 145°C for 7 hours, turn on the vacuum pump, and remove the methanol and Excessive N,N-dimethylpropylenediamine, to obtain erucic acid acyl tertiary amide product, then add the required amount of sodium chloroacetate, react at 75°C for 10 hours, and obtain long carbon chain after recrystallization and purification with absolute ethanol Betaine surfactant; Wherein, methyl erucate: N,N-dimethylpropylenediamine: the mol ratio of sodium chloroacetate is 1:2:1.5.

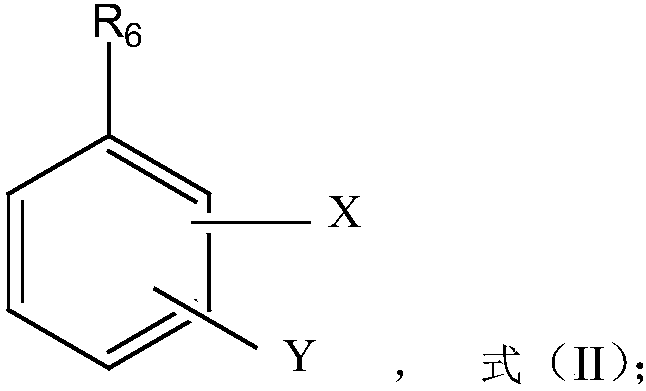

[0035] b) Hydroxyl-substituted benzene carboxylate and the erucamide carboxy betaine surfactant prepared by the present invention were dissolved in water respectively, stirred for 30 minutes, and formulated into an aqu...

Embodiment 2

[0044] 1. Surfactant Preparation

[0045] (1) palmitic acid amide carboxy betaine surfactant (R 1 =C 15 , R 2 =C 2 , R 3 =C 3 , R 4 , R 5 =C 1 ) preparation

[0046] a) Add 0.5 mole of long carbon chain hexadecanoic acid methyl ester and the required amount of amidating reagent N,N-dimethylethylenediamine into the reaction kettle, react at 130°C for 6 hours, turn on the vacuum pump, and pump out the reaction Produced methanol and excess N,N-dimethylethylenediamine to obtain hexadecanoyl tertiary amine product, then add the required amount of β-chloropropionate and react at 70°C for 12 hours, then use absolute ethanol After recrystallization and purification, a long carbon chain betaine surfactant is obtained; wherein, the molar ratio of methyl palmitate:N,N-dimethylethylenediamine:sodium β-chloropropionate is 1:2:1.6.

[0047] b) The hydroxy-substituted benzene carboxylate and the palmitic acid amide carboxy betaine surfactant prepared by the present invention are re...

Embodiment 3

[0051] 1. Surfactant Preparation

[0052] (1) triacic acid amide carboxy betaine surfactant (R 1 =C 29 , R 2 =C 3 , R 3 =C 3 , R 4 , R 5 =C 1 ) preparation

[0053] a) Add 0.5 moles of long-chain triacic acid methyl ester and the required amount of amidating reagent N,N-dimethylpropylenediamine into the reaction kettle, react at 150°C for 8 hours, turn on the vacuum pump, and pump out the reaction Produced methanol and excess N,N-dimethylpropylenediamine to obtain triacyl tertiary amine product, then add the required amount of β-chloropropionate sodium, react at 85°C for 16 hours, and dry Obtain the long carbon chain betaine surfactant after ethanol recrystallization purification; Wherein, triacic acid methyl ester:N,N-dimethylpropylenediamine: the molar ratio of β-sodium chloropropionate is 1:2:1.6 .

[0054] b) Hydroxy-substituted benzene carboxylate and the triacic acid amide carboxy betaine surfactant prepared by the present invention were dissolved in water res...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com