Patents

Literature

63results about How to "Strong reference value" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

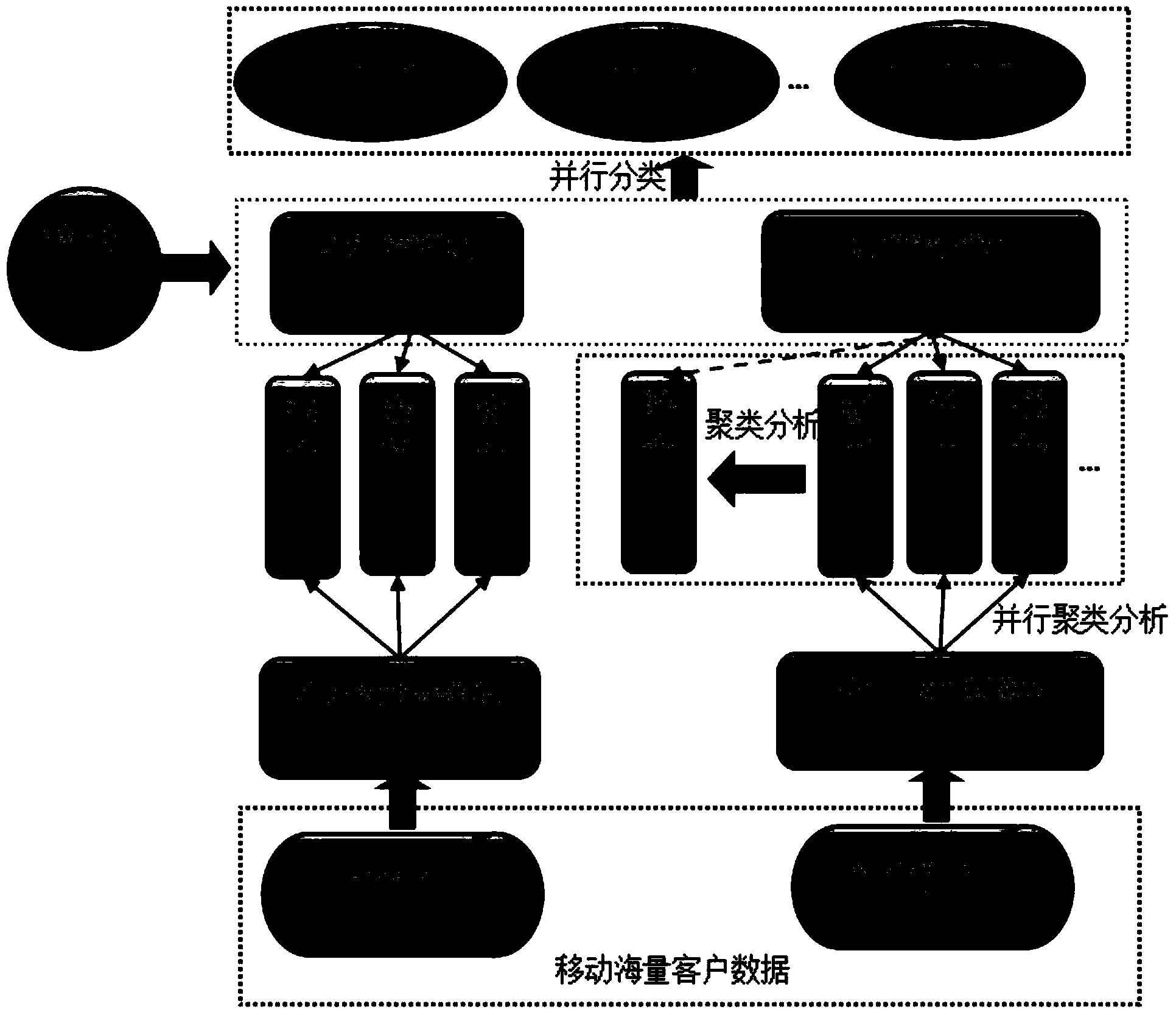

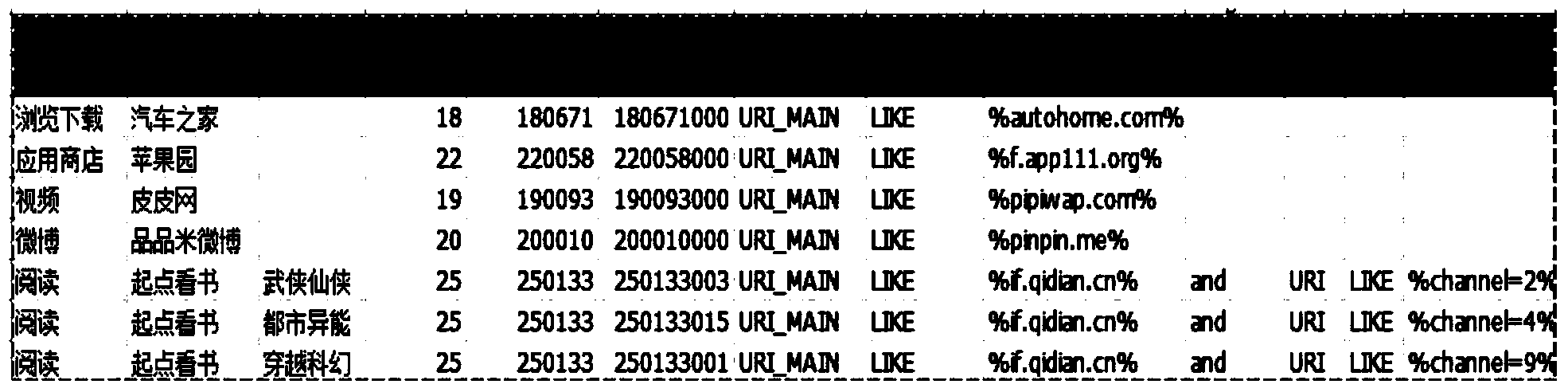

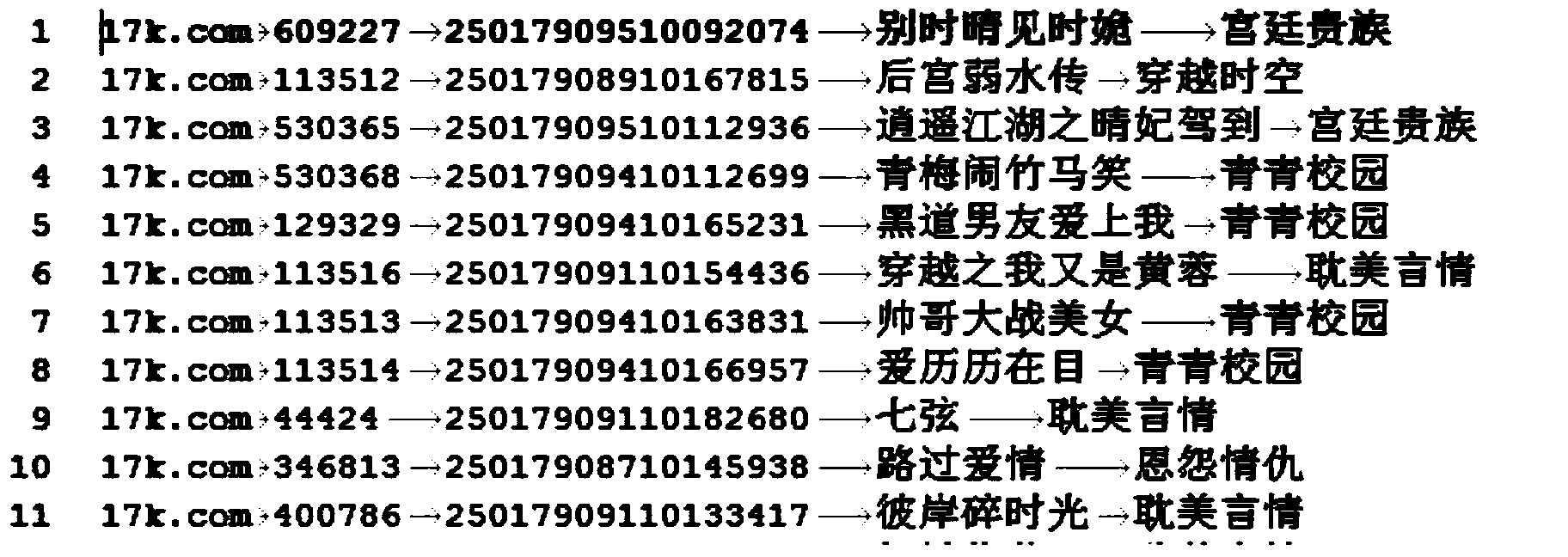

Parallel data mining method for identifying a mass of mobile client bases

ActiveCN103714139AStrong reference valueEfficient data mining analysisMarketingSpecial data processing applicationsThe InternetPurchasing

The invention discloses a parallel data mining method for identifying a mass of mobile client bases. The parallel data mining method includes the steps of building a client value model and a client behavior model, classifying clients according to the client value model and the client behavior model, popularizing assigned preference services to the clients with the high purchasing power and the high potential purchasing inclination, and then achieving accurate marketing. According to the parallel data mining method, the mass of mobile client bases can be identified, the aspects such as Internet surfing time preferences, Internet surfing place preferences and browsed website preferences of the clients can be identified, and the social group classes of the clients can be accurately judged. Clustering and classifying can be rapidly carried out through the adopted parallel clustering algorithm and the adopted parallel classifying algorithm. By means of the parallel data mining method, different strategies can be formulated for the different client bases by an enterprise, and the important guiding function for profit maximization of the enterprise is achieved.

Owner:SOUTH CHINA UNIV OF TECH

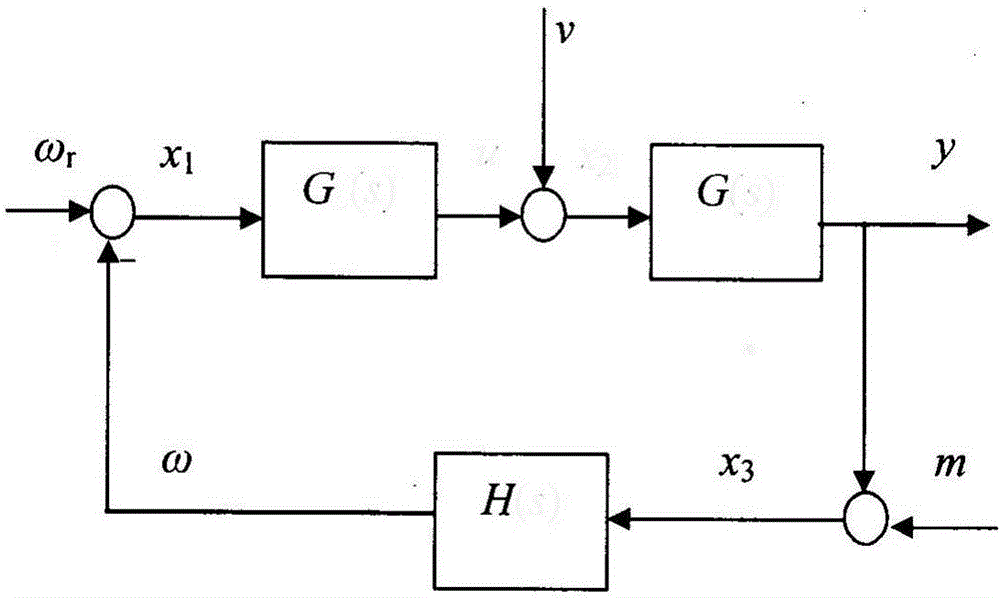

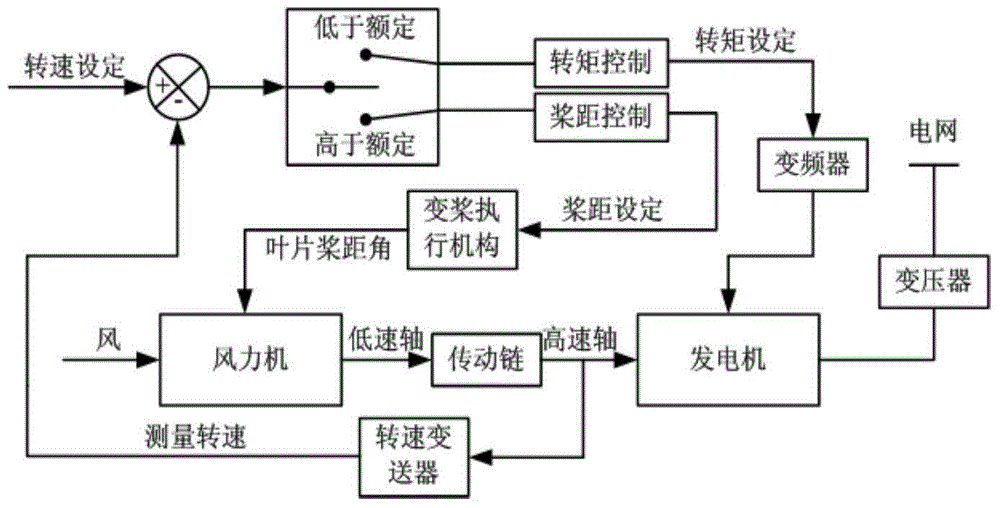

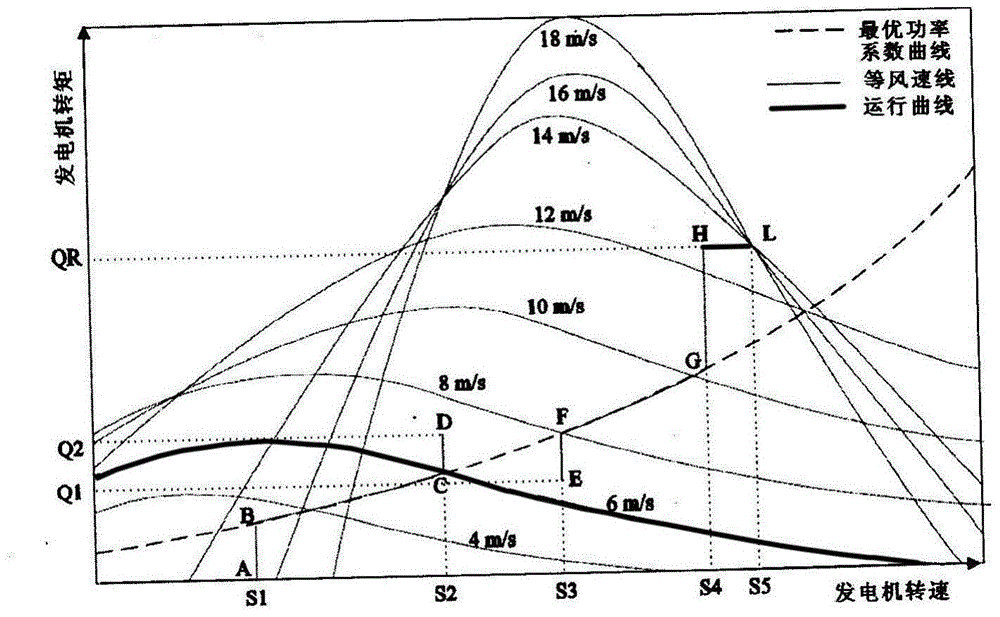

Method for identifying and setting parameters of wind generating set controller

InactiveCN104533714APracticalStrong reference valueWind motor controlEngine fuctionsEngineeringBlade pitch

The invention discloses a method for identifying and setting parameters of a wind generating set controller, and belongs to the technical field of control over a wind generating set. The method comprises the steps that a Bladed software model is utilized for being linearly combined with a model order reduction algorithm to build a unit linear model suitable for setting the parameters; and then, according to the wind speed distribution probability of a wind field, optimal setting and comprehensive calculation of PI parameters of the controller are carried out, and on the basis of a parameter identifying result of Bladed software, an optimum rotary speed-torque control gain coefficient and a gain factor in self-adaptation variable pitch control are calculated. Identifying of related parameters such as a largest wind energy utilization coefficient, an optimum tip-speed ratio and an optimal propeller pitch angle is carried out according to a Bladed simulation model built according to unit equipment parameters, and the important prerequisite condition is provided for control over maximal wind energy capture of the unit is provided; the self-adaptation variable pitch control is achieved, and the robustness of a common PI variable pitch controller is improved; and the guidance is provided for design and optimization of the controller, and the method has the higher practical and reference value.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

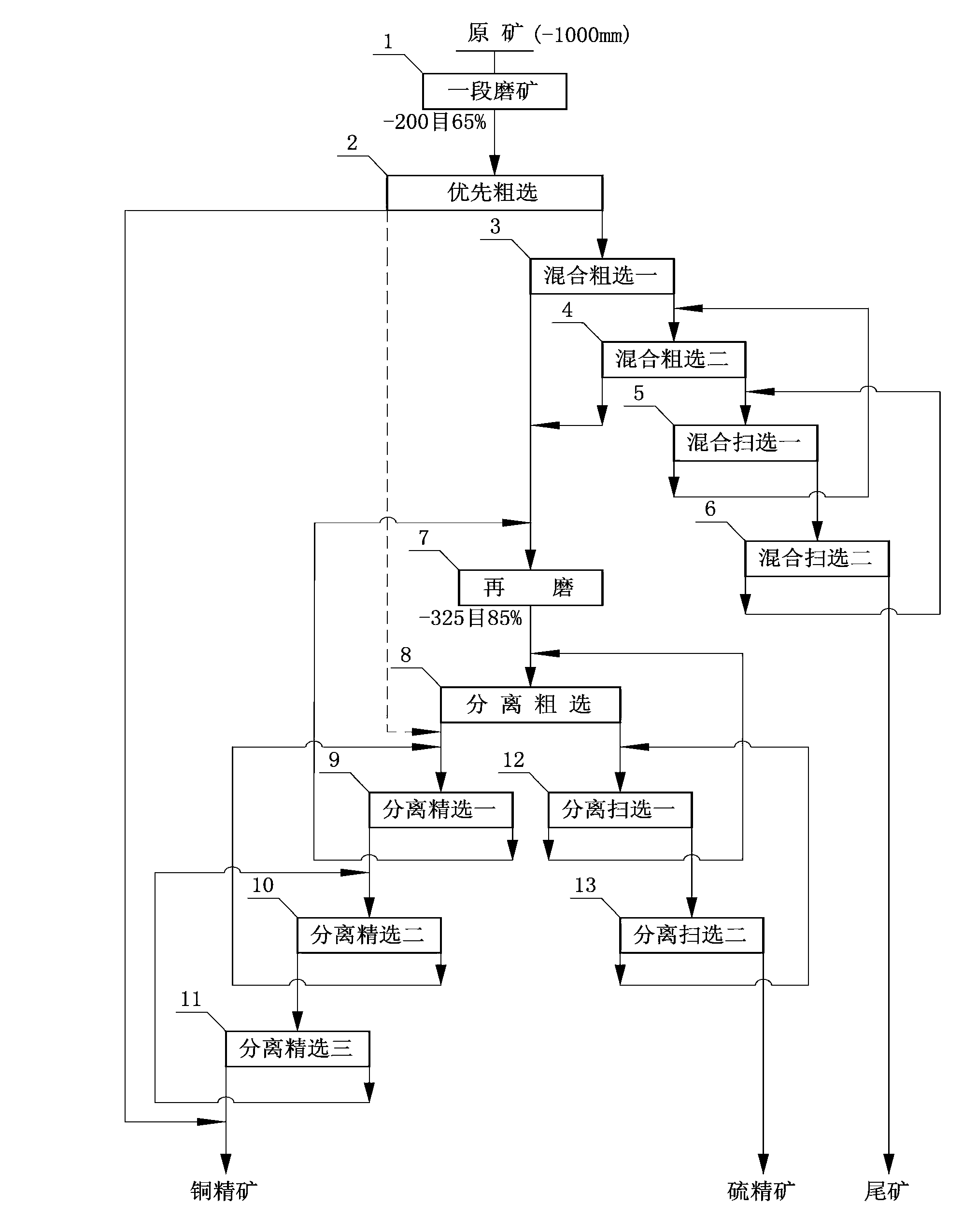

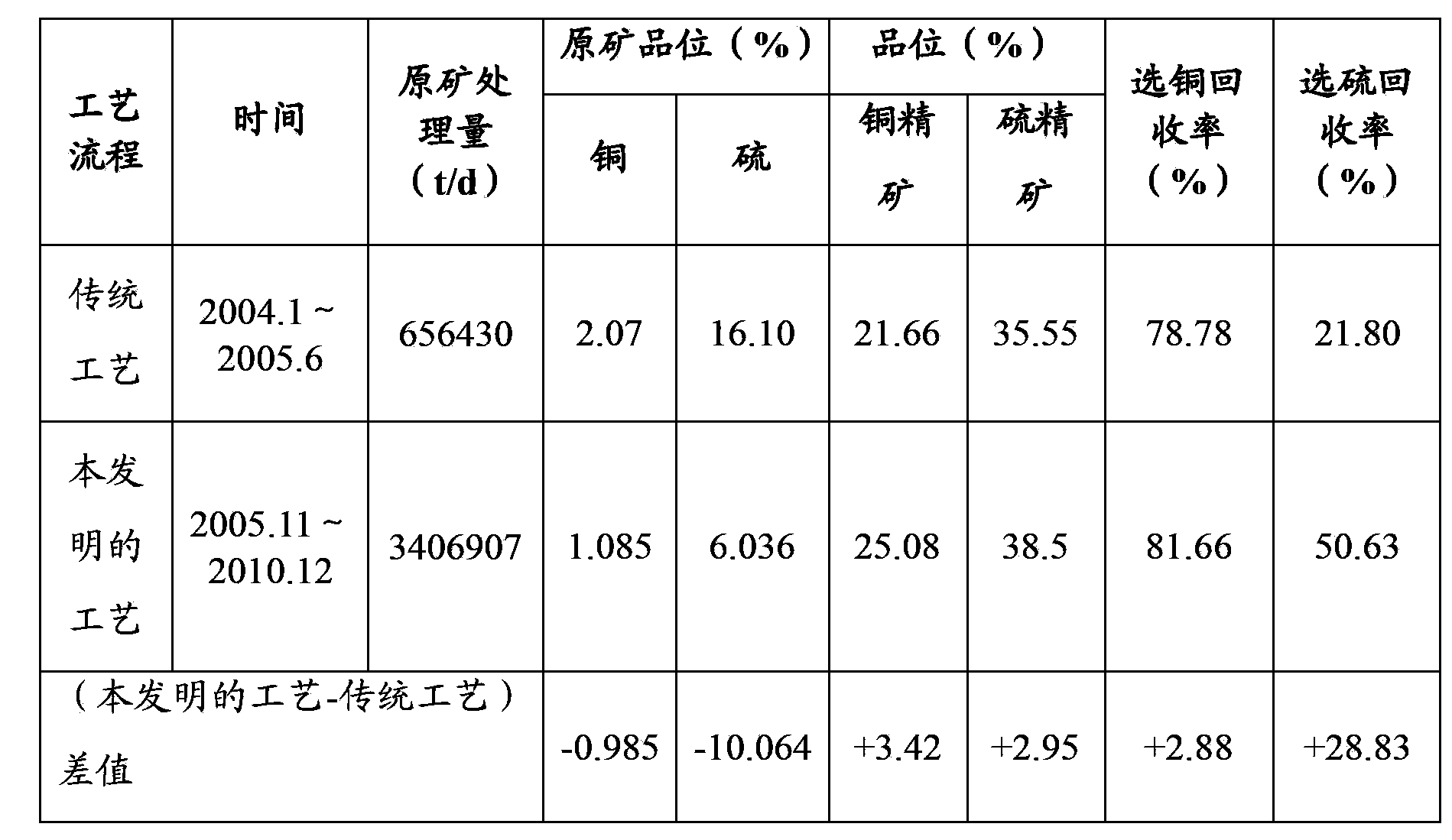

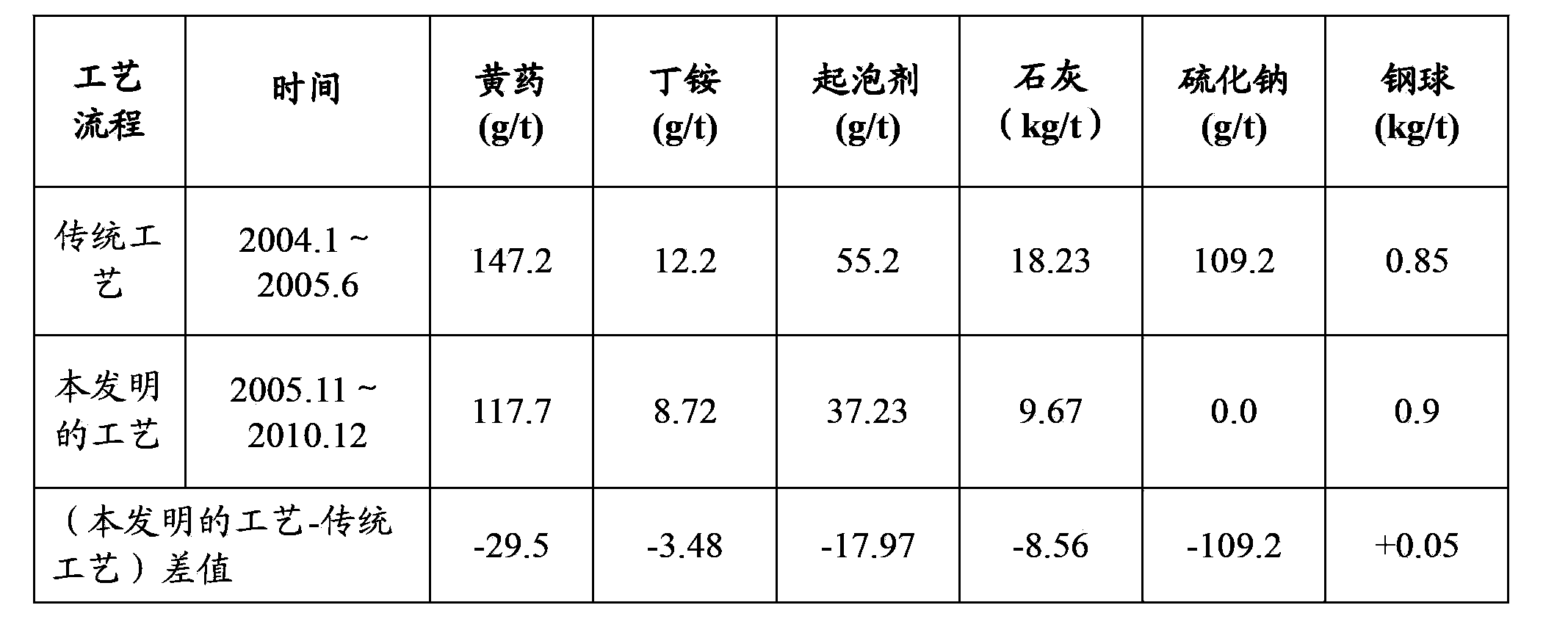

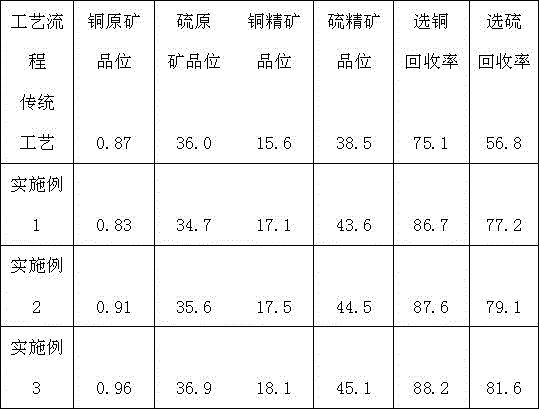

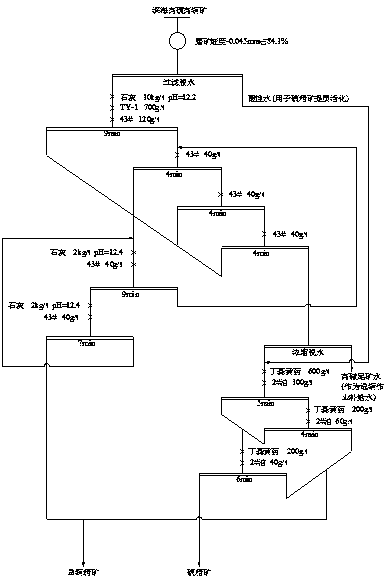

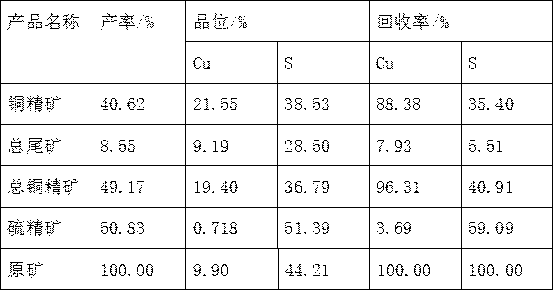

Flotation method for copper sulphide ore

The invention relates to a flotation method for copper sulphide ore. The method comprises the following steps of (1) performing primary grinding on the copper sulphide ore so as to obtain a primary grinding product; (2) performing first flotation on the primary grinding product by utilizing a first trapping agent so as to obtain a monomer copper mineral and secondary copper-rich mineral intergrowth-contained first flotation product and first flotation residues; (3) performing second flotation on the first flotation residues by utilizing a second trapping agent so as to obtain copper-poor intergrowth, complex copper mineral and free sulfur-contained a second flotation product and second flotation tailings; (4) performing secondary grinding on the second flotation product so as to obtain a secondary grinding product; and (5) performing copper-sulfur separation on the secondary grinding product in a strong caustic environment so as to obtain copper concentrate and sulfur concentrate. By utilizing the flotation method for the copper sulphide ore provided by the invention, copper-sulfur flotation can be effectively performed on the complex and refractory copper sulphide ore.

Owner:CHINA NERIN ENG

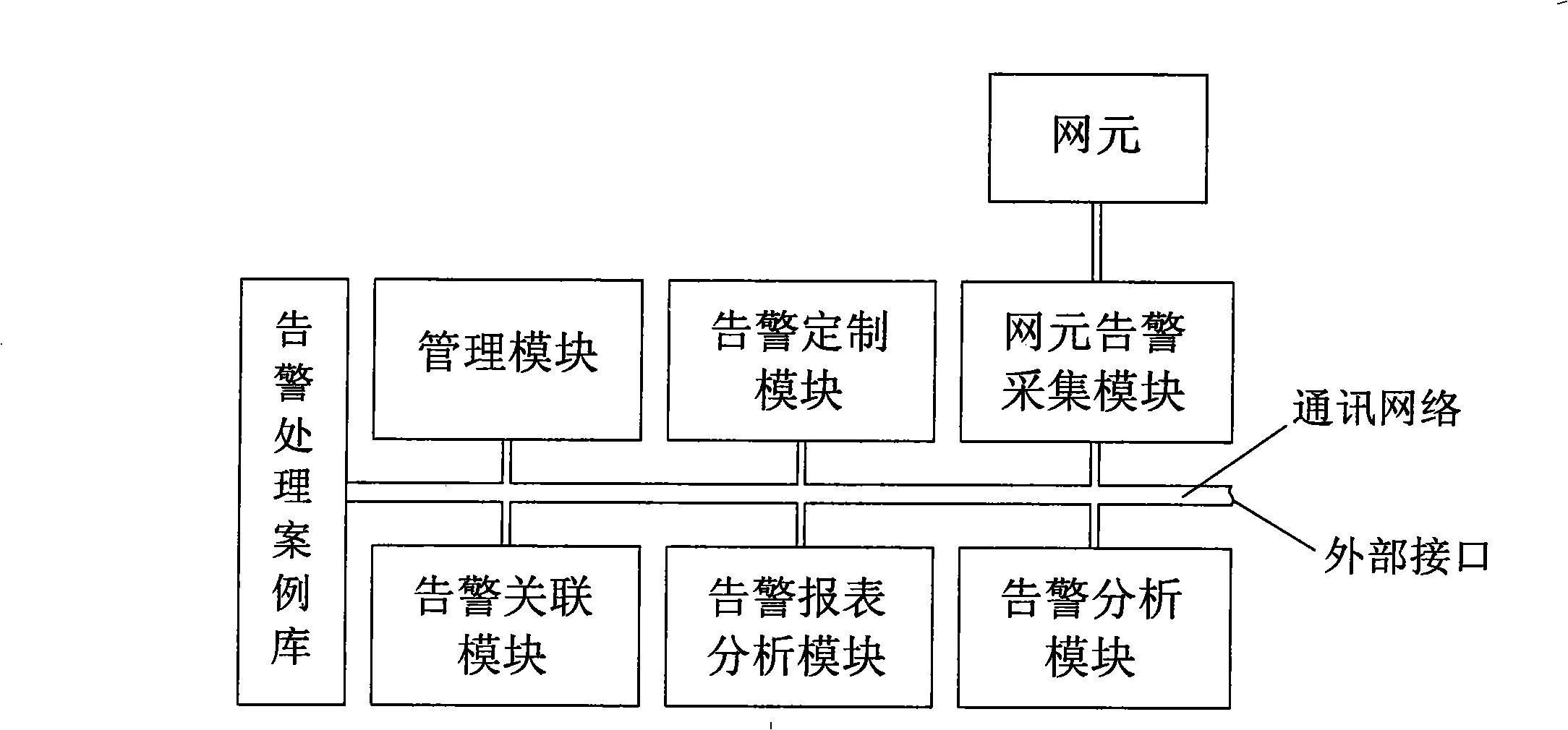

Network element alarming intelligent monitoring system

InactiveCN101345972ARealize centralized monitoringRealize separate collectionSupervisory/monitoring/testing arrangementsRadio/inductive link selection arrangementsMonitoring systemSmart surveillance

The invention relates to a mobile communication technique domain, especially a network element alarm intelligent monitoring system, comprising network element alarm acquisition modules connected by communication network, managing modules and alarm customization modules, wherein the network element alarm acquisition modules are connected with network elements to acquire network element alarms and store the alarm in an alarm bank based on alarm signal and alarm content classification; and the user is subjected to identification authentication by the managing modules and the related authorizations are allocated; the alarm customization modules immediately sends short message to maintenance personnel to pre-warn when the alarm exceeds the threshold based on network element alarm threshold defined by authorized users. The system can perform centralized monitor and alarm to whole network elements to handle the network element alarm in time.

Owner:CHINA MOBILE GRP FUJIAN CO LTD

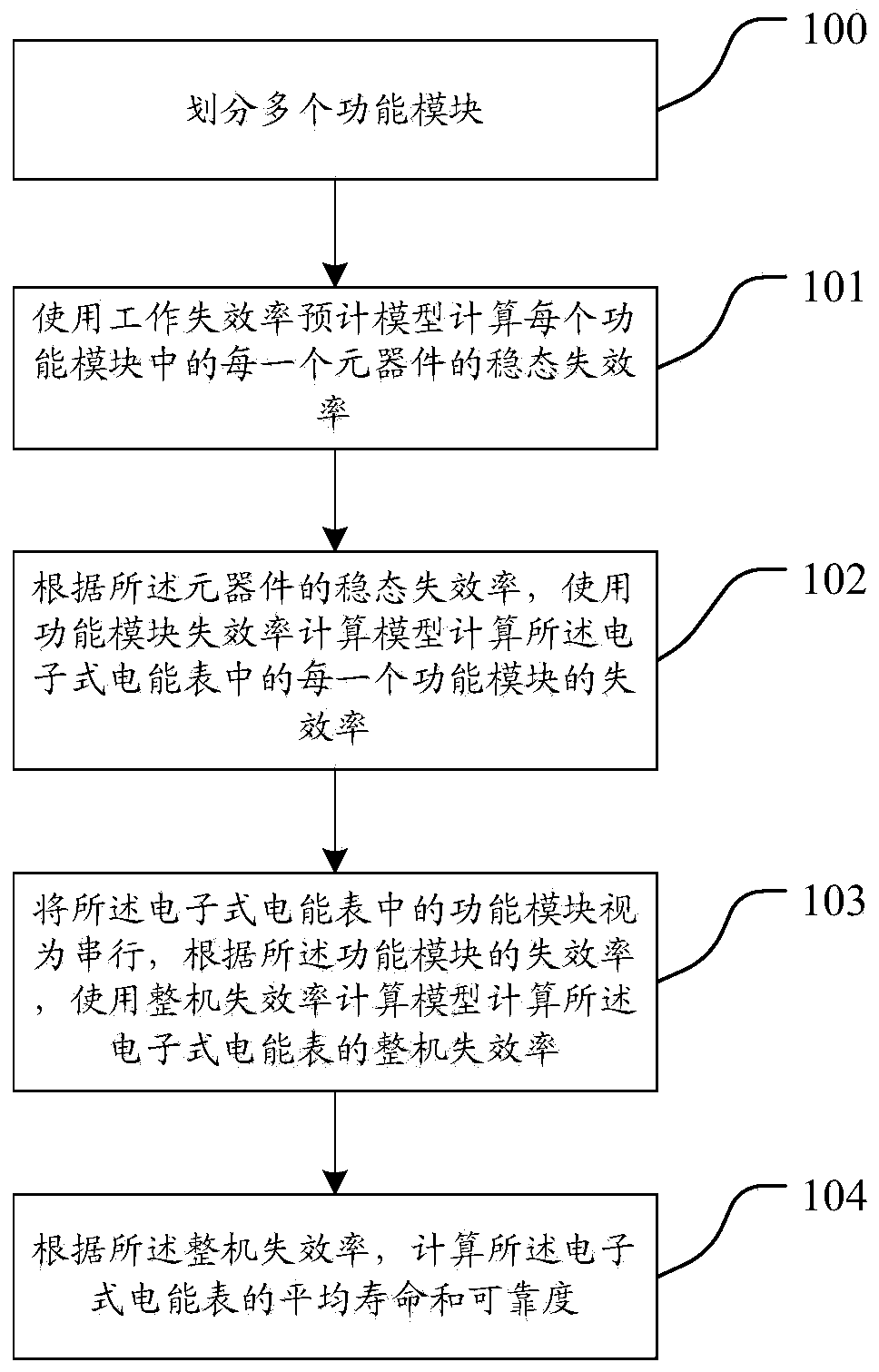

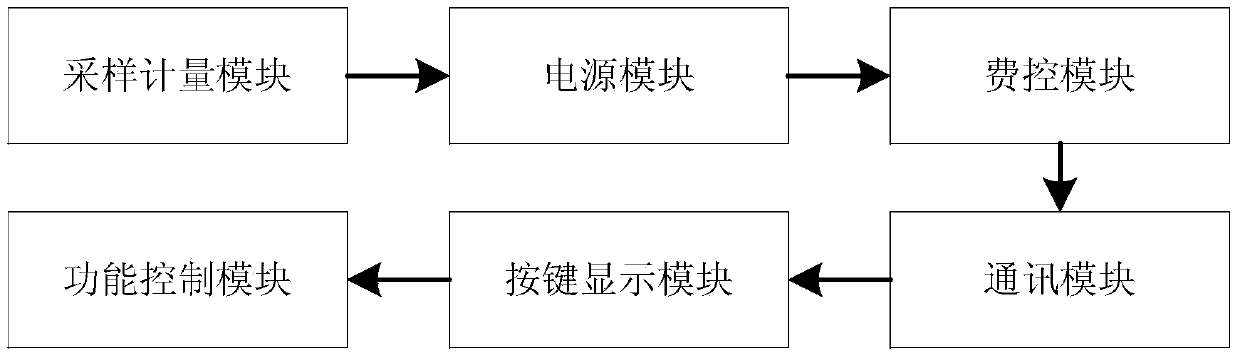

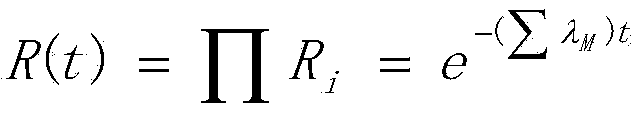

Method for analyzing reliability of electronic watt-hour meter

InactiveCN103745081AStrong reference valueImprove work efficiencySpecial data processing applicationsFailure rateLife time

The invention provides a method for analyzing reliability of an electronic watt-hour meter. The method includes the steps of firstly, dividing the electronic watt-hour meter into a plurality of functional modules according to functions, and setting the significance weights of the functional modules to be the same; secondly, calculating steady-state failure rates of all elements in all the functional modules through a working failure rate forecasting model; thirdly, calculating failure rates of all the functional modules in the electronic watt-hour meter through a functional module failure rate calculating model according to the steady-state failure rates of the elements; fourthly, taking the functional modules in the electronic watt-hour meter as serial, and calculating the overall failure rate of the electronic watt-hour meter through an overall failure rate calculating model according to the failure rates of the functional modules; fifthly, calculating the average service life and the reliability degree of the electronic watt-hour meter according to the overall failure rate. By means of the method for analyzing reliability of the electronic watt-hour meter, credibility of forecasting results on the service life and the reliability degree of the electronic watt-hour meter can be remarkably improved.

Owner:SHENZHEN POWER SUPPLY BUREAU

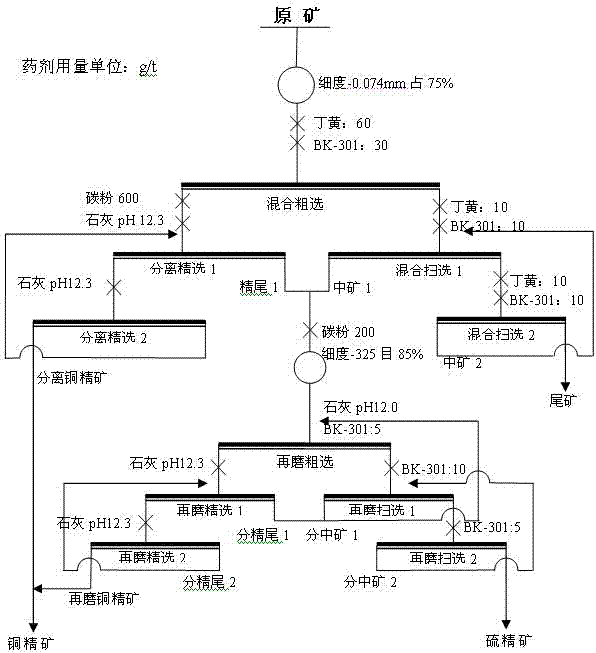

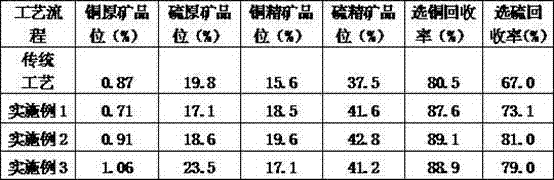

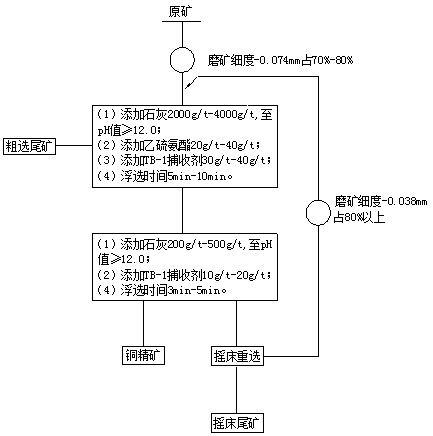

Method for recycling copper minerals from high-sulfur rebellious copper ore step by step

InactiveCN104759353ASolve the problems of low grade and high loss rate of copper in sulfur concentrateSolve the problem of excessive loss rateFlotationSulfurEconomic benefits

The invention discloses a method for recycling copper minerals from high-sulfur rebellious copper ore step by step. The method comprises the following steps: (1) crushing and grinding raw ore; (2) mixing and crude selection; (3) mixing and scavenging I; (4) mixing and scavenging II; (5) separation and fine selection I; (6) separation and fie selection II; (7) grinding of reground middling ore; (8) regrinding and crude selection; (9) regrinding and scavenging I; (10) regrinding and scavenging II; (11) regrinding and fine selection I; (12) regrinding and fine selection II. The beneficial effects are as follows: the method for recycling copper minerals from high-sulfur rebellious copper ore adopts mixing and bulk flotation, regrinding and selection of middling ores and step-by-step recycling; the method solves the problems of lower copper concentrate grade and recycling rate, over-high loss ratio of copper in sulfur concentrate caused by non-uniform copper and sulfur insetting grain size and thin copper ore insetting grain size; the method is important to improve economic benefits of enterprises and societies.

Owner:TONGLING NON FERROUS METAL GROUP CORP

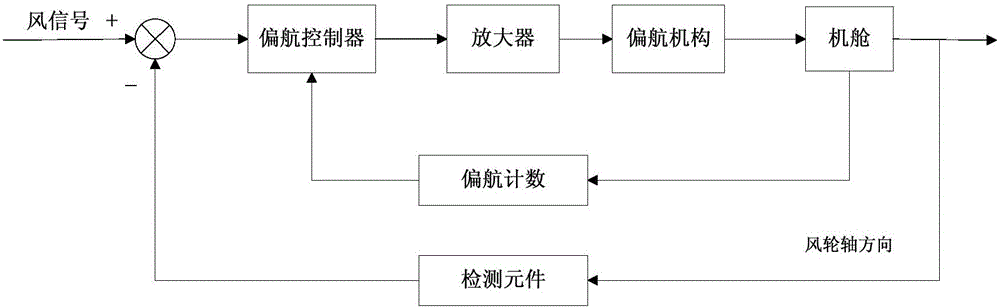

SCADA data-based yaw control parameter optimization method for wind generation set

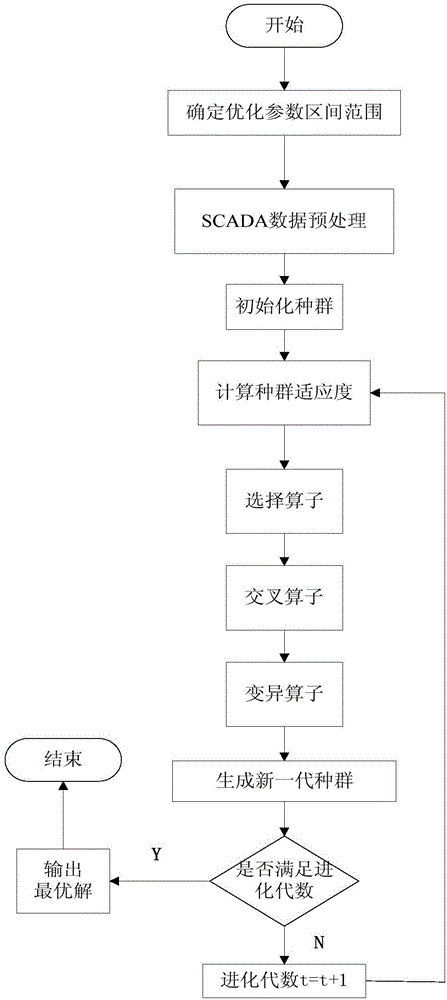

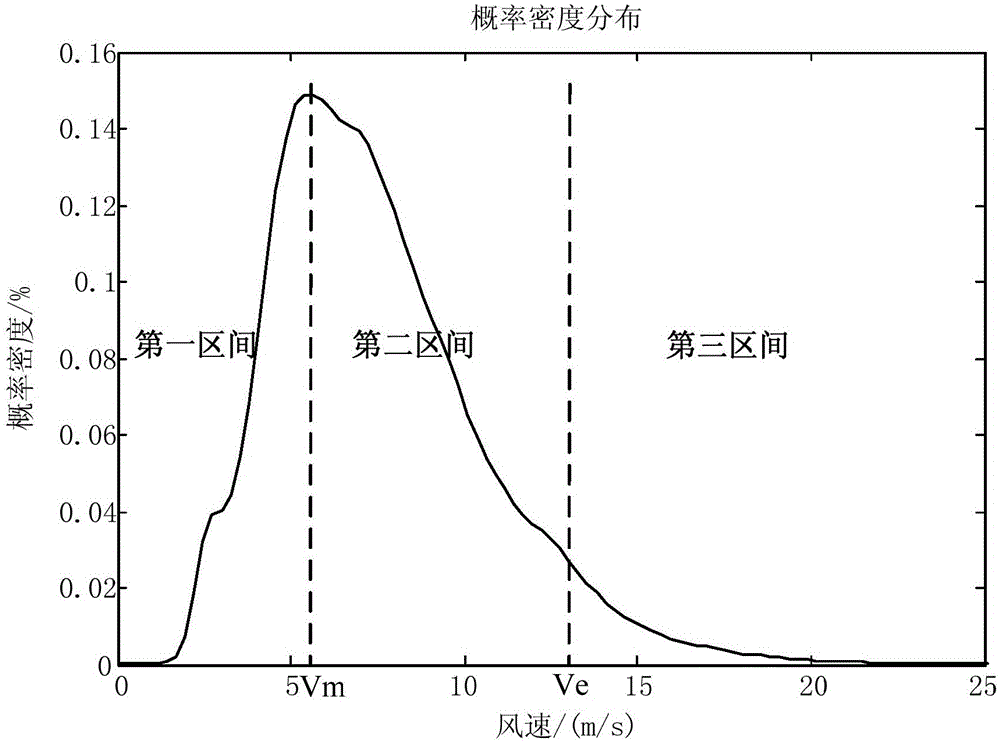

InactiveCN106286130APracticalStrong reference valueOptimise machine performanceWind motor controlElectricityMutation operator

The invention belongs to the technical field of wind generation set control, and particularly relates to an SCADA data-based yaw control parameter optimization method for a wind generation set. The method specifically comprises the steps that firstly, parameter optimization intervals are determined; the optimization ranges of optimized yaw control parameters, namely yaw deviation threshold values and delay time; SCADA data is preprocessed; an initial population is generated; fitness function values are calculated; the selection probability Psi of each individual is calculated on the basis of the fitness function values; selection is performed by adopting a roulette wheel method, so that a parent is obtained for breeding a next-generation population; a new population is generated from the initial population by utilizing a crossover operator and a mutation operator; and if the number of iterations is larger than a maximum number of genetic generations, calculation is terminated, and optimum yaw deviation threshold values and delay time are output. By adopting the method, an optimized result has a higher self-adaption level and higher pertinence; and the output performance of the generation set is obviously enhanced, and yaw time cannot be obviously improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

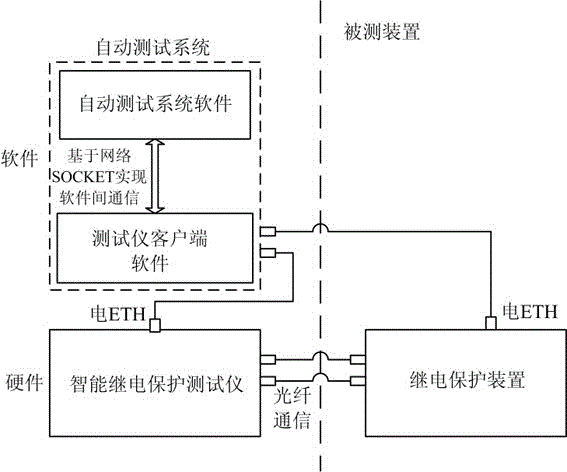

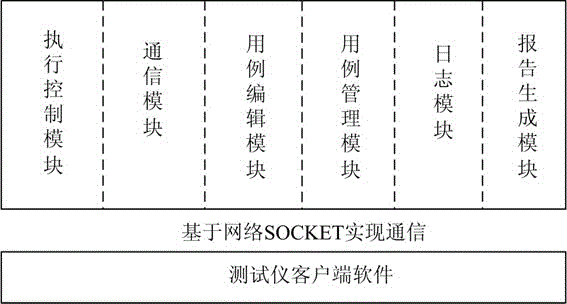

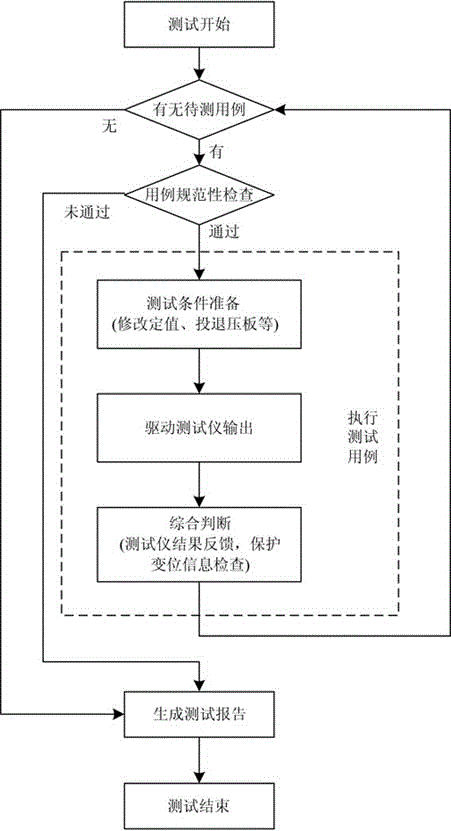

Automatic testing system for relay protection device of intelligent substation

The invention relates to an automatic testing system for a relay protection device of an intelligent substation. The system is composed of automatic testing system software, tester client software, an intelligent relay protection tester and a relay protection device; the automatic testing system software is in interprogram communication with the tester client software through a SOCKET, and the functions of downwards sending a tester control command and feeding back a testing result are achieved; the automatic testing system software is in unicast communication with the relay protection device to be tested on the basis of an IEC61850 standard by adopting an MMS communication protocol, the functions of downwards sending a protection device control command and obtaining information such as device operation reporting, wave recording and remote signaling deflecting are achieved, the automatic testing system software achieves dispatching control over a testing task and result judgment, and therefore full-automatic closed-loop testing is achieved finally. The design idea and implementation method of the system have a high reference value to links such as debugging and acceptance checking of an intelligent substation project, and the system has wide application and popularization prospects.

Owner:孙文兵

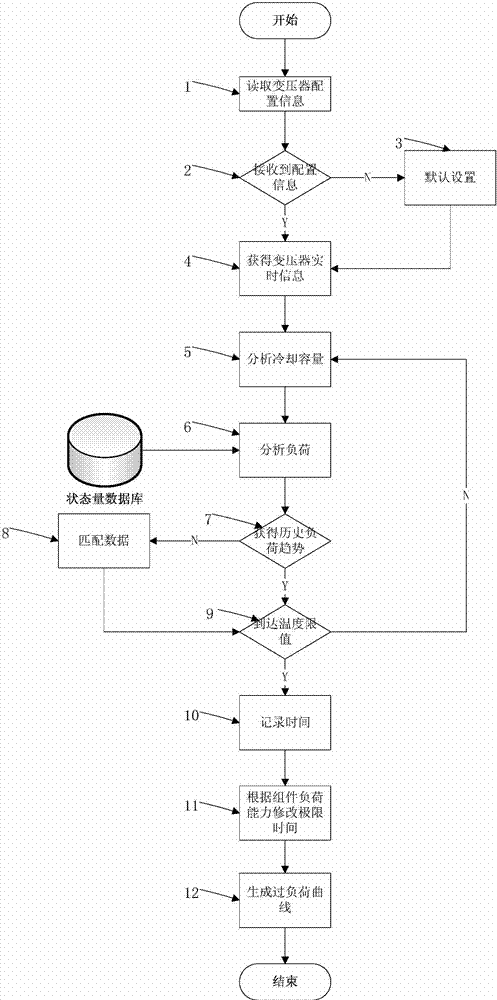

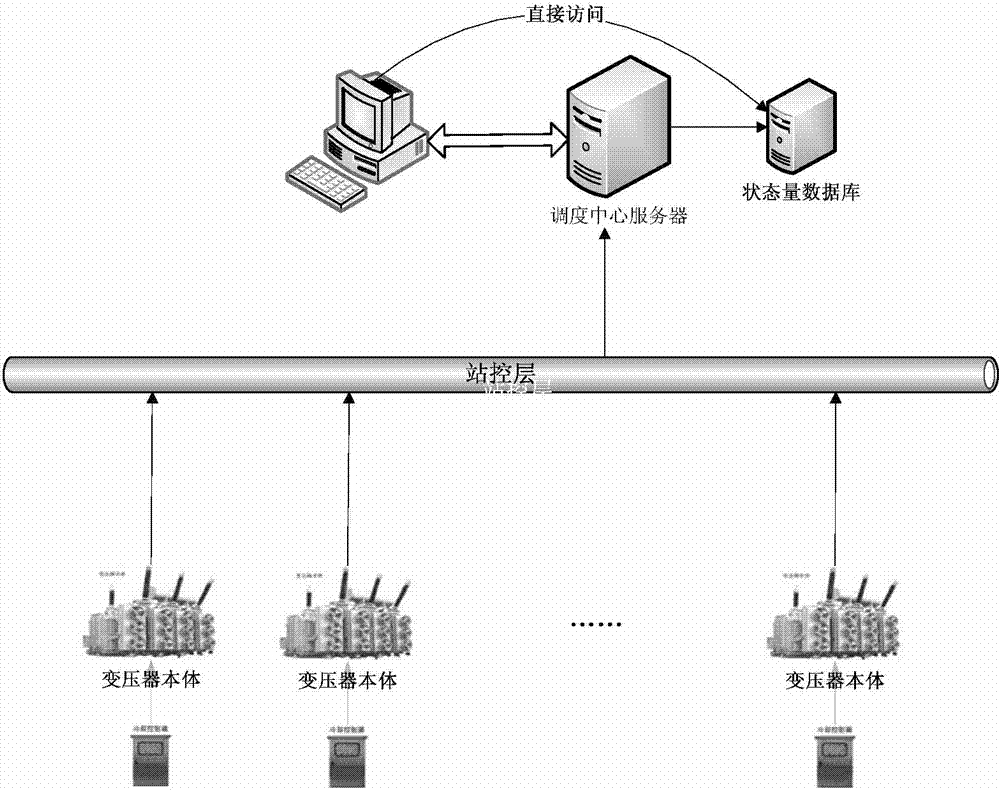

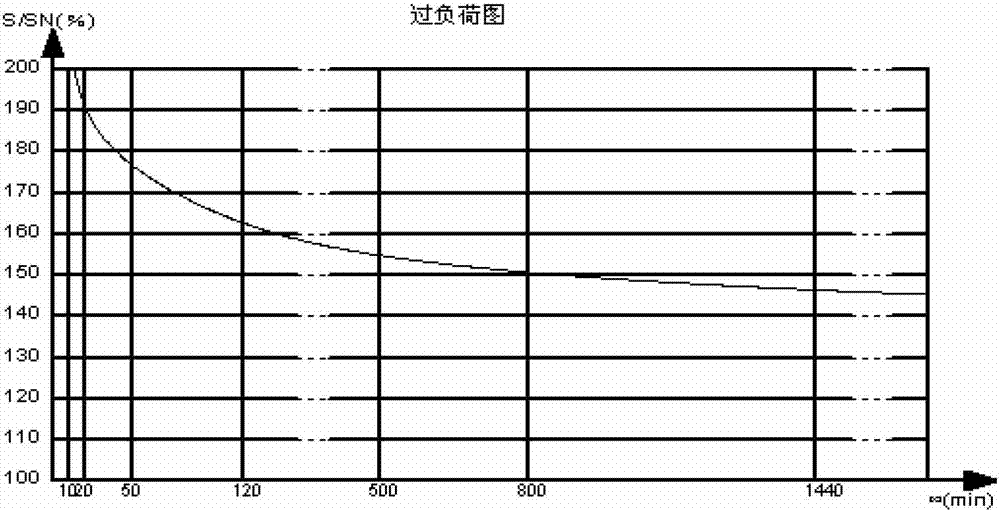

Method for determining dynamic overload curves of transformers based on operating data

ActiveCN103543352AForecasting future loadFully tap the overload capacityElectrical testingReal-time dataTransformer

The invention discloses a method for determining dynamic overload curves of transformers based on operating data. The method includes: A), adapting basic configuration subjected to overload curve calculation according to basic configuration information of the transformers to the transformers different in types and cooling ways; B), reading real-time operating data of the transformers to complete preparation for real-time data of the transformers; C), calculating cooling capacity of the transformers and initiating cooing power of the transformers; D), analyzing historical load trend of the transformers and forecasting future loads of the transformers; E), calculating hot-limit time of the transformers according to the winding hot-spot temperature of the transformers; F), modifying the hot-limit time of the transformers according to overload capacity tables of initialized transformer tables; G), matching the overload curves by adopting a Bezier grid to complete and determine dynamic overload curve graphs of the transformers. Since the dynamical overload curve graphs can be generated by the method, scientific and effective reference can be provided for load control.

Owner:STATE GRID CORP OF CHINA +2

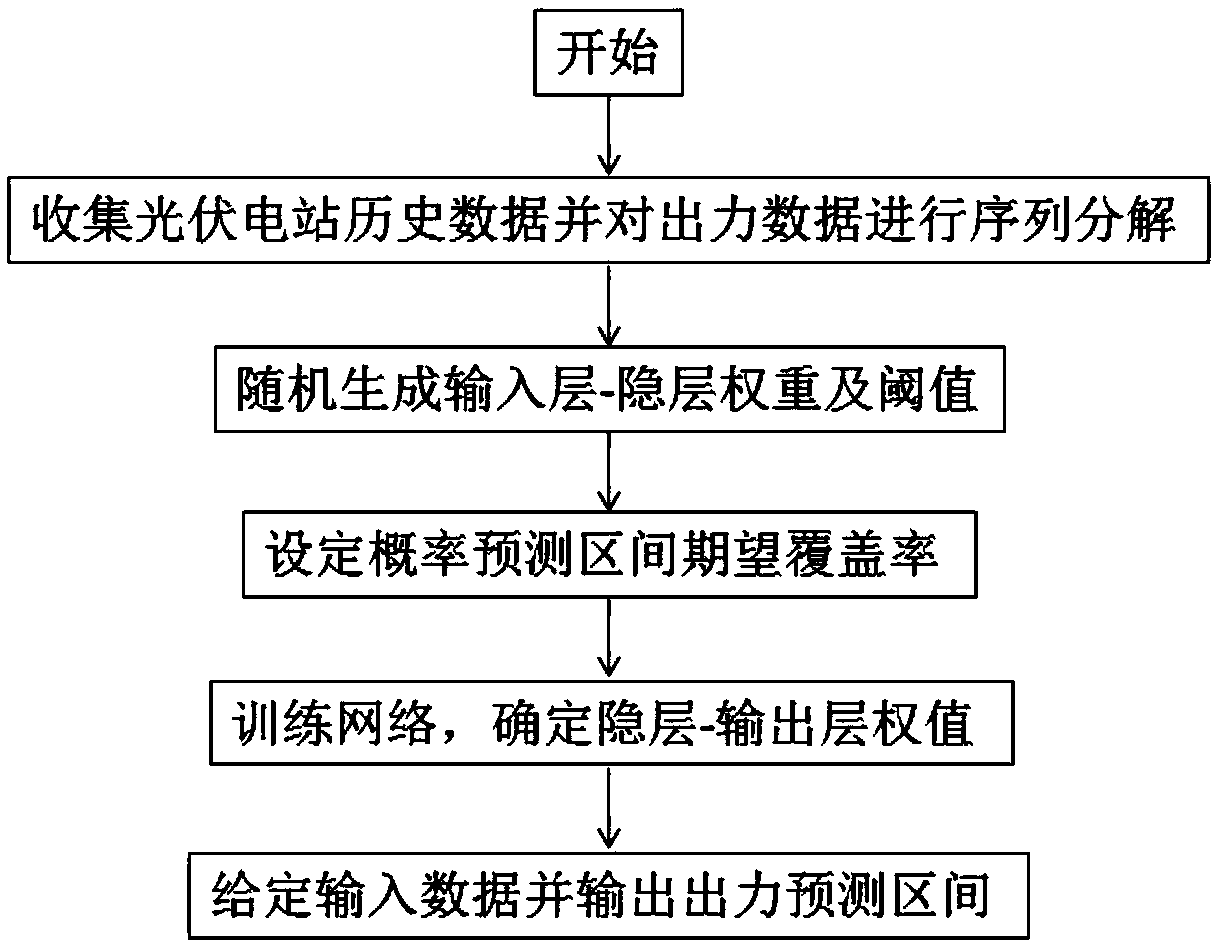

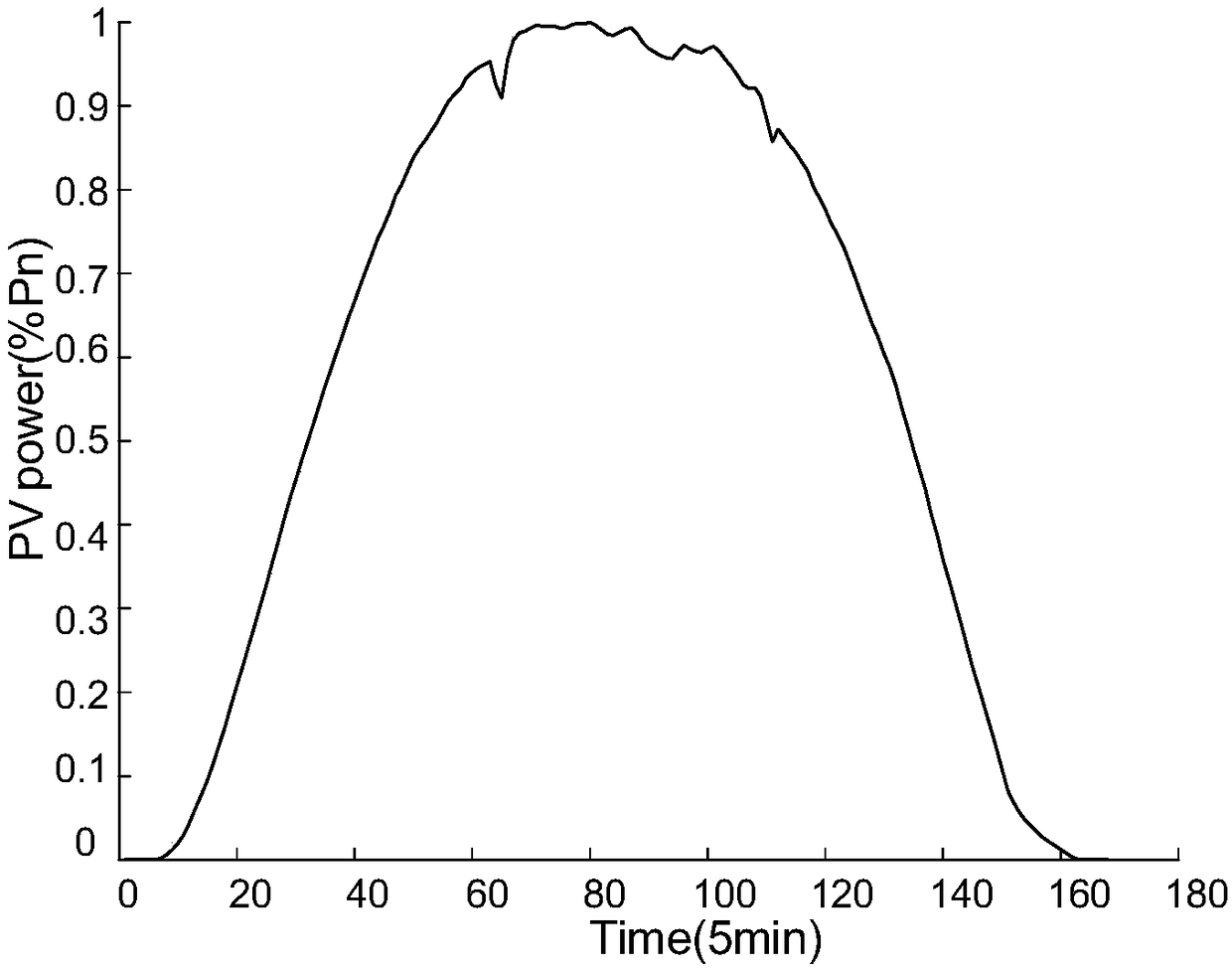

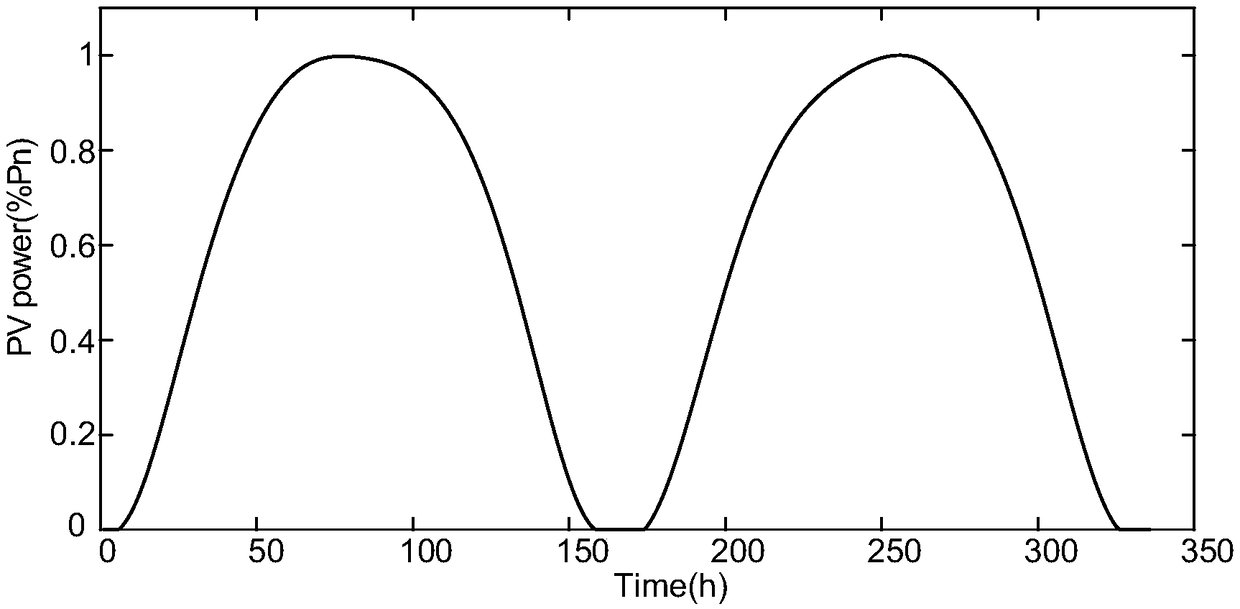

A method for predict photovoltaic probability

ActiveCN109376951AAddressing the Impact of Conversion EfficiencyImprove forecast accuracyForecastingNeural architecturesDecompositionPrediction interval

The invention discloses a photovoltaic probability prediction method, which comprises the following steps: (1) collecting historical data of a photovoltaic power station and performing sequence decomposition on the historical output data; (2) randomly generating input layer-Hidden layer weight and offset; (3) Setting the expected coverage rate of probability prediction interval; (4) Training the network to determine the hidden layer Weights of the output layer; (5) inputting data to obtain output prediction interval. As that historical output of the photovoltaic power station is taken as a model input, the invention solves the influence of the randomness of the mount position of the photovoltaic array and the use time of the photovoltaic array on the conversion efficiency, and improves theprediction accuracy; Decomposition of historical data can more effectively distinguish the influence of different factors on output and enhance the characteristics of data. Introducing the idea of limit learning machine ELM, the training speed is greatly improved while the precision is guaranteed; Quantile regression is used to predict the probability of photovoltaic output interval, which has astronger reference value for the formulation of dispatch plan.

Owner:HUAZHONG UNIV OF SCI & TECH +3

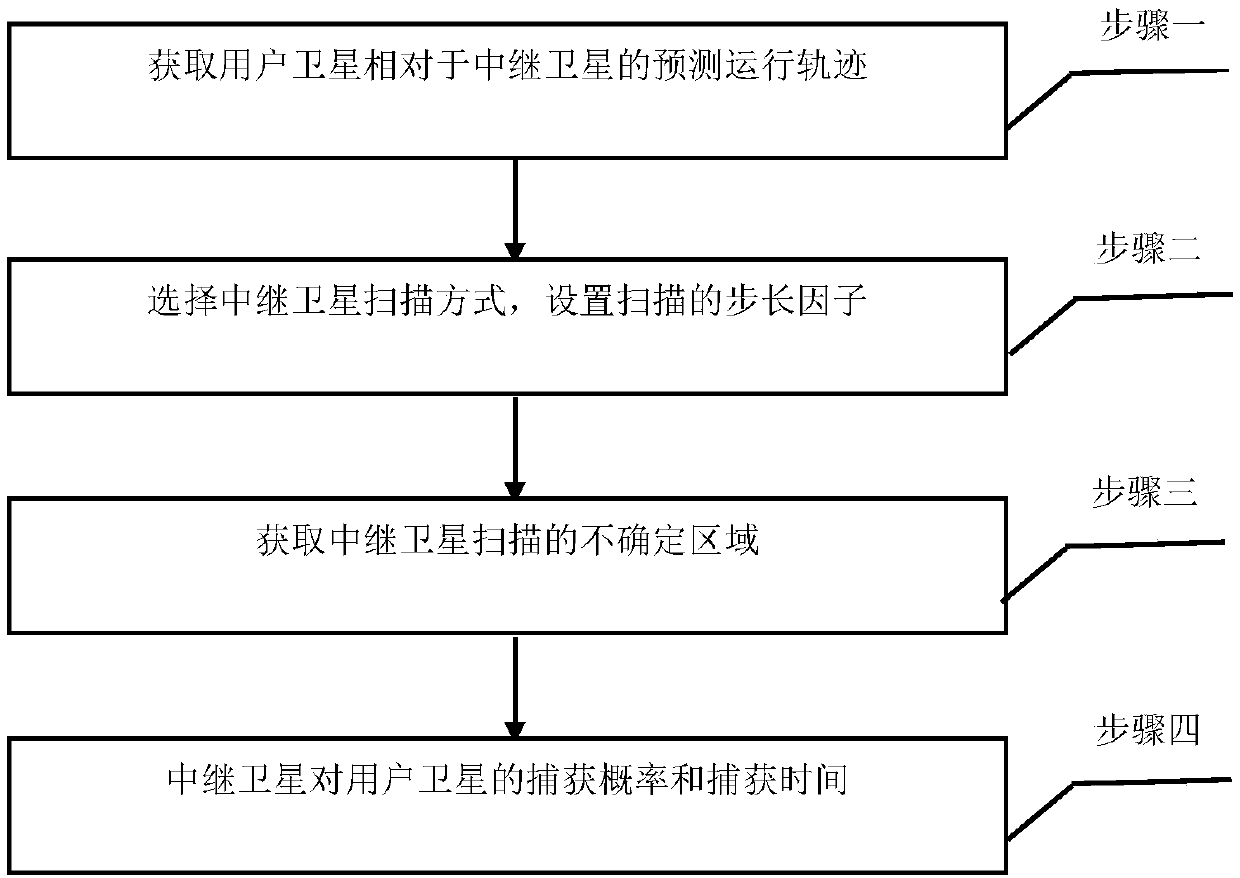

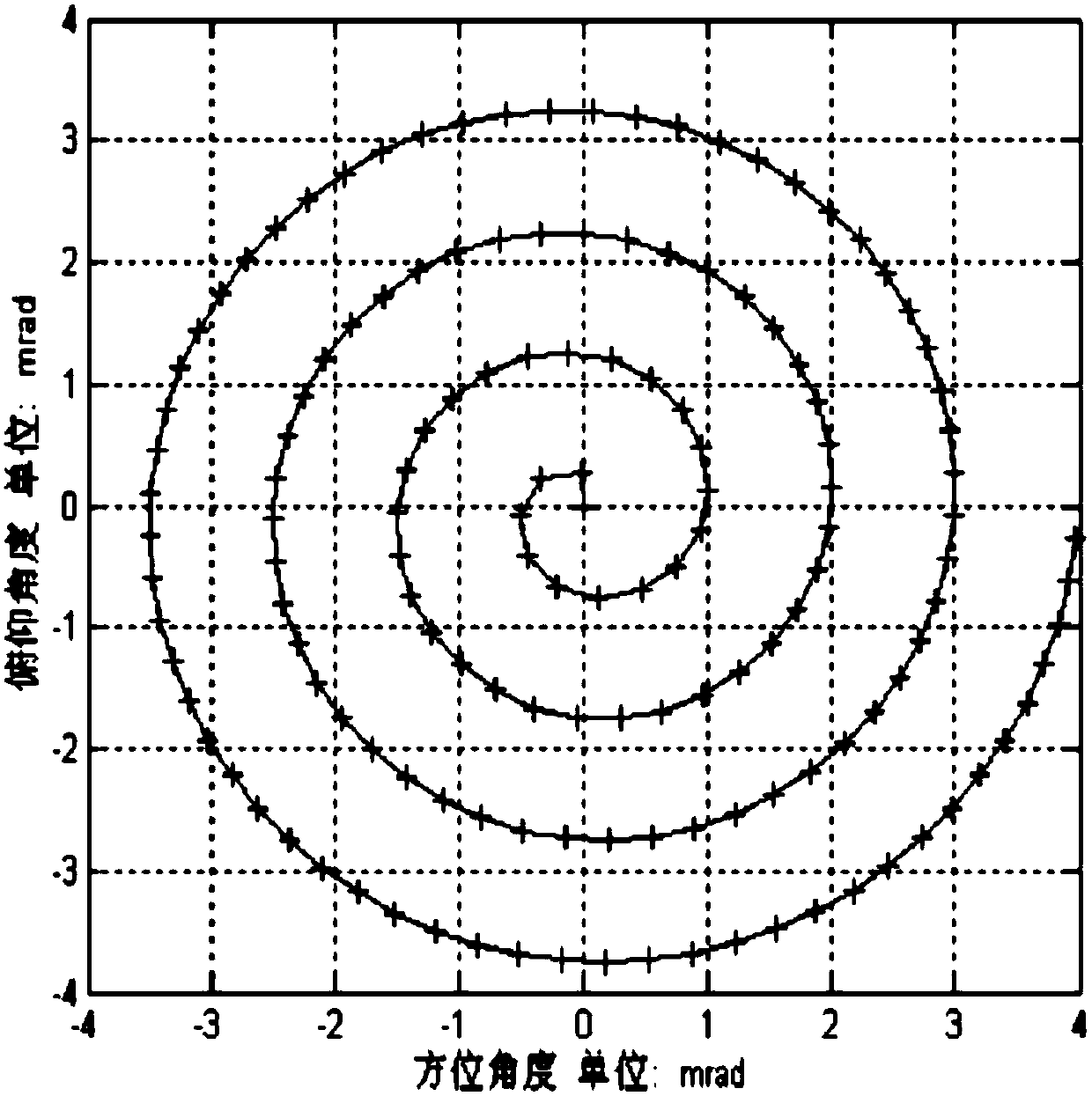

Simulation method of signal acquisition process of inter-satellite link based on orbit prediction

ActiveCN109543292ASimulation results are accurateAdjust capture strategyDesign optimisation/simulationSpecial data processing applicationsAcquisition timeOrbit prediction

The simulation method of signal acquisition process of inter-satellite link based on orbit prediction is used in the field of satellite communication technology. The invention solves the problem thatthe signal acquisition process of the inter-satellite link between the medium-low orbit satellites cannot be accurately described by the traditional simulation method. The invention considers the influence of the motion trajectory of the user satellite, Therefore, the simulation result obtained based on the invention can be more accurate, and the significance of the invention also lies in that after accurately obtaining the acquisition time and the acquisition probability of the medium and low orbit targets, the acquisition strategy used in the satellite acquisition process can be adjusted, and the simulation result has strong practical reference value. The invention can be applied to the field of satellite communication technology.

Owner:HARBIN INST OF TECH

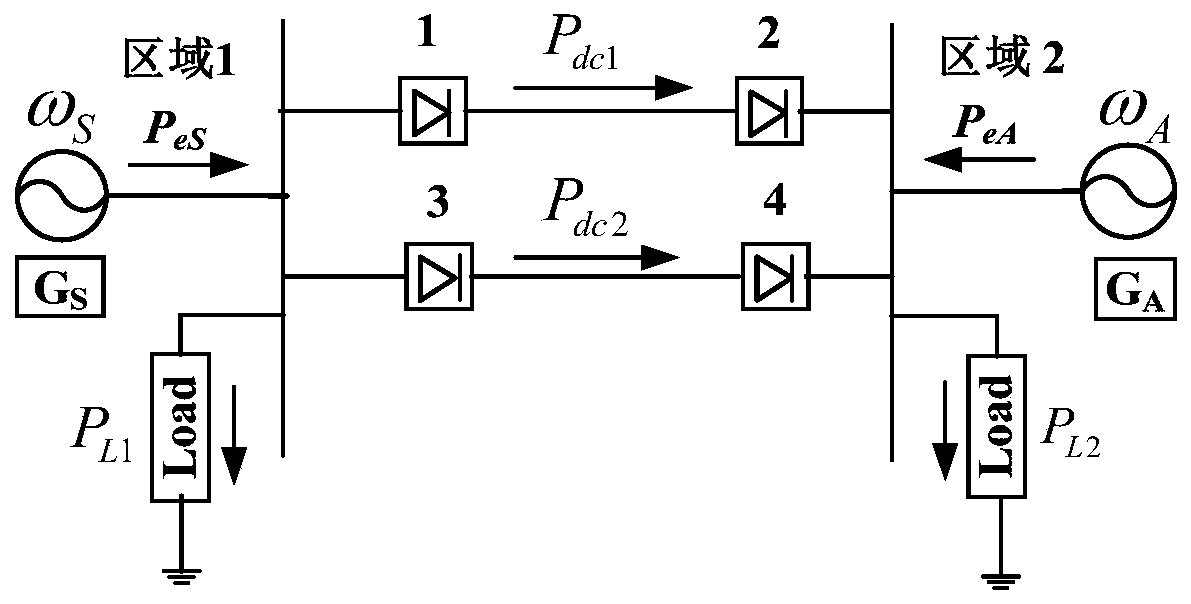

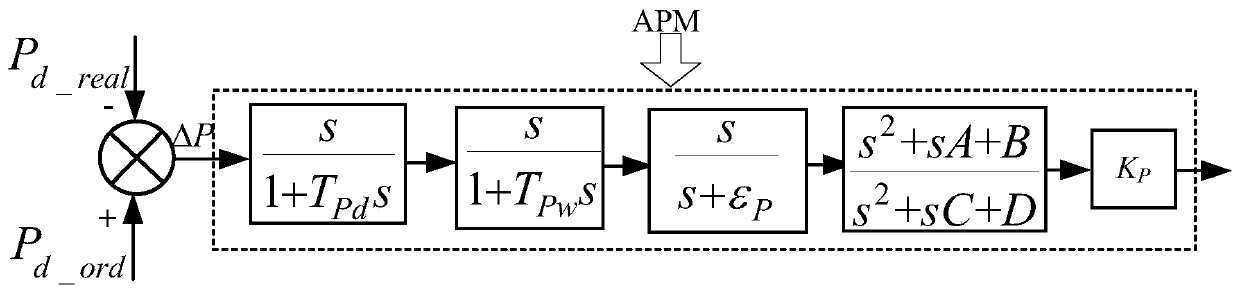

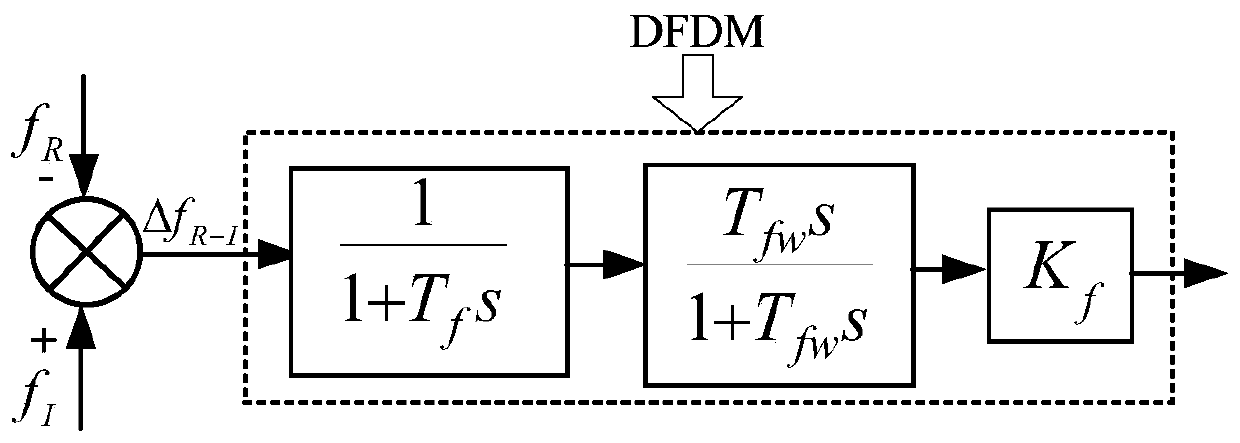

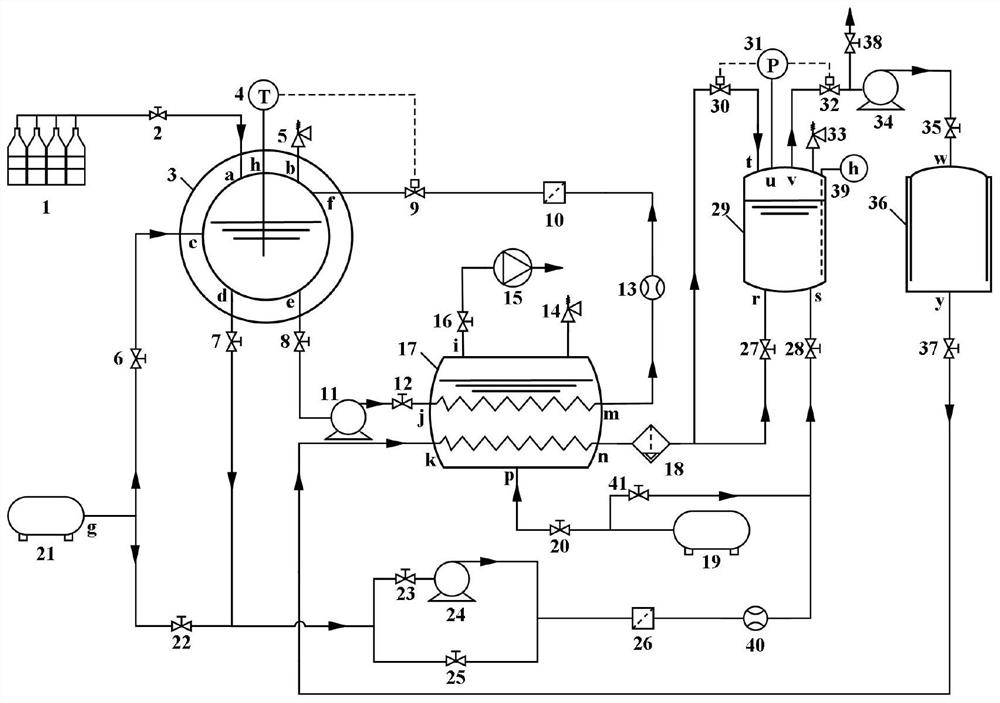

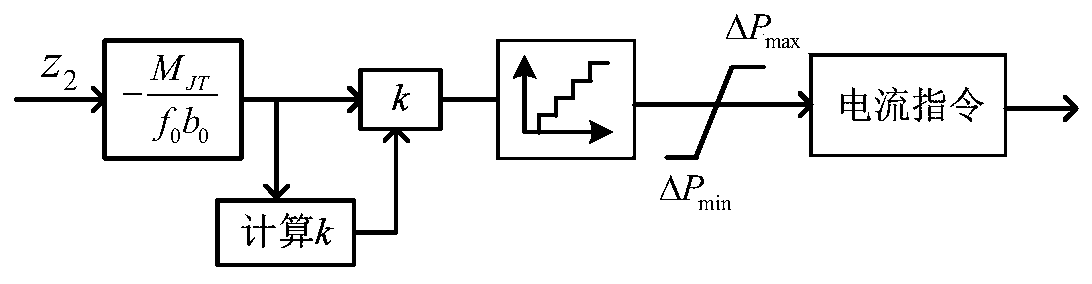

Multi-infeed direct-current auxiliary power/frequency combination controller coordination optimization control method

ActiveCN110492499AJustifyRealize emergency controlElectric power transfer ac networkPower oscillations reduction/preventionTransient stateMathematical model

The invention provides a multi-infeed direct-current auxiliary power / frequency combination controller coordination optimization control method, which comprises the following steps of: establishing a mathematical model of a multi-infeed direct-current power transmission system according to a connection relationship of the multi-infeed direct-current power transmission system; solving a multi-infeedinteraction factor, a multi-infeed effective short-circuit ratio and a multi-infeed power support factor of the multi-infeed direct-current power transmission system in a mode of applying small disturbance; determining the final DC power boosting amount of each loop; judging the tie line fault by measuring whether the power of the tie line is suddenly reduced to 0 or not; obtaining a multi-infeeddirect-current auxiliary power / frequency combined controller structure by adopting an active power large-mode controller and a bilateral frequency difference controller structure. The multi-infeed effective short-circuit ratio proportionality coefficient and the multi-infeed power support factor proportionality coefficient are adopted to perform emergency control on an internal fault of the alternating current system and a tie line fault disturbance form, so that coordination and optimization of emergency control of the multi-infeed direct current interconnected power system are realized, andthe transient stability of the system is improved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

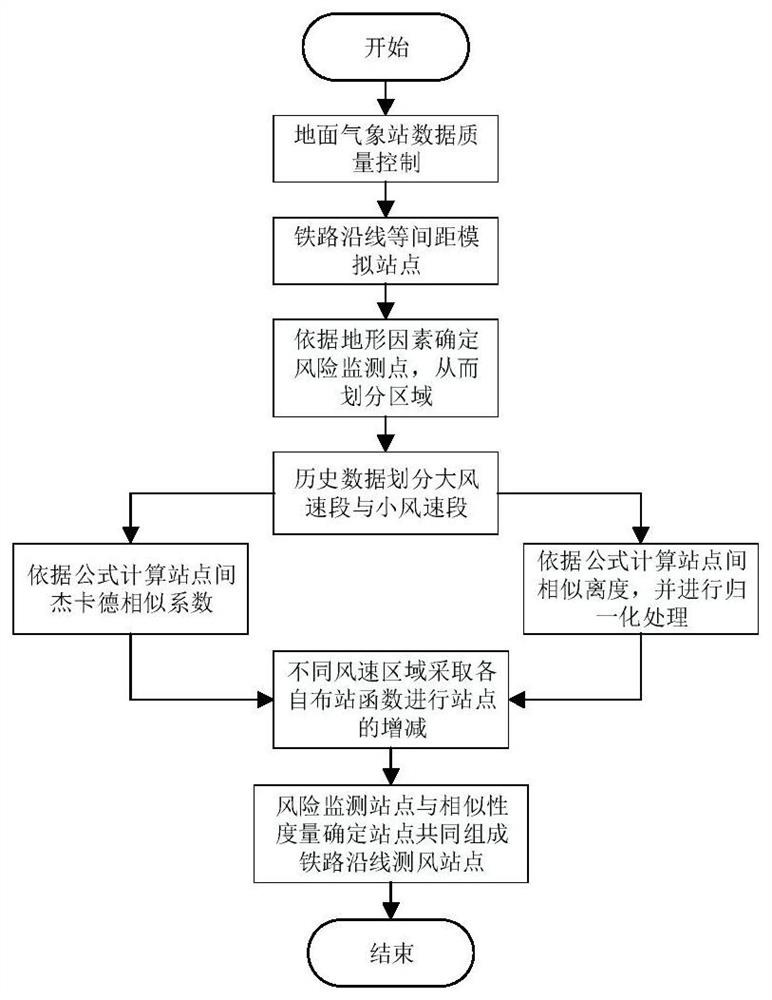

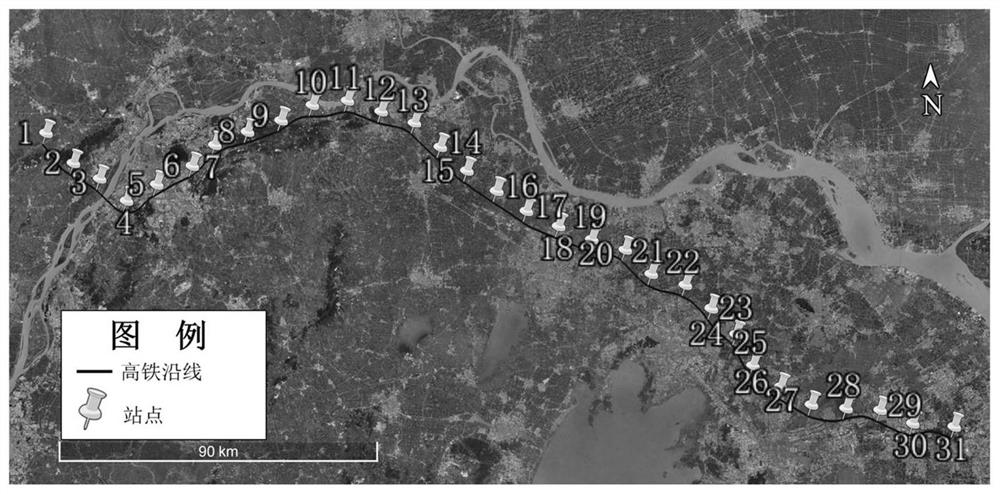

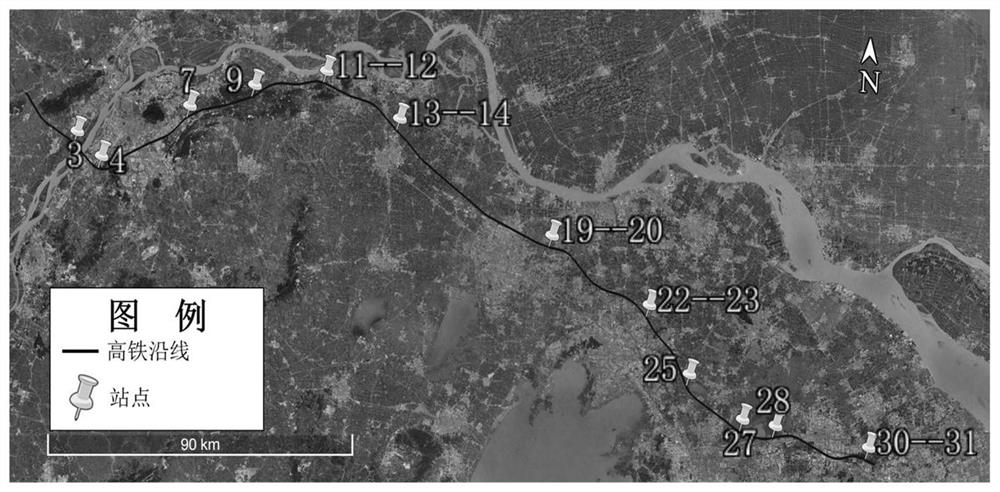

Method for optimizing layout of wind measurement stations along high-speed rail

ActiveCN113011029ASmall time complexityMonitor wind speed characteristicsCharacter and pattern recognitionDesign optimisation/simulationData sourceEngineering

The invention discloses a method for optimizing layout of wind measurement stations along a high-speed rail, which comprises the following steps of: selecting wind speed data of meteorological stations within a certain range along the high-speed rail, carrying out preliminary quality control on the wind speed data as a data source, and simulating wind speed data of wind measurement stations at equal intervals along the high-speed rail through Kriging interpolation; taking the simulated stations as existing wind measurement stations along the rail, dividing the rail along the railway into a plurality of area sections according to the landforms of the wind measurement stations, finally increasing and decreasing the wind measurement stations through an improved similarity function, and improving equal-interval station distribution of the wind measurement stations into non-uniform station distribution. Therefore, the wind speed characteristics of each area can be accurately monitored with the minimum number of stations. According to the invention, cost can be saved, and the wind speed characteristics along the line can be accurately monitored.

Owner:NANJING UNIV OF INFORMATION SCI & TECH

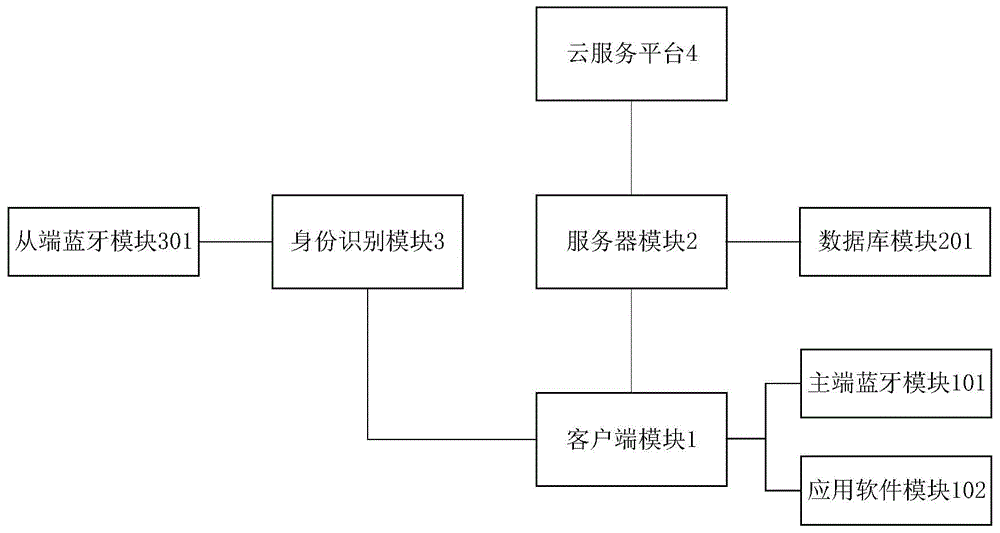

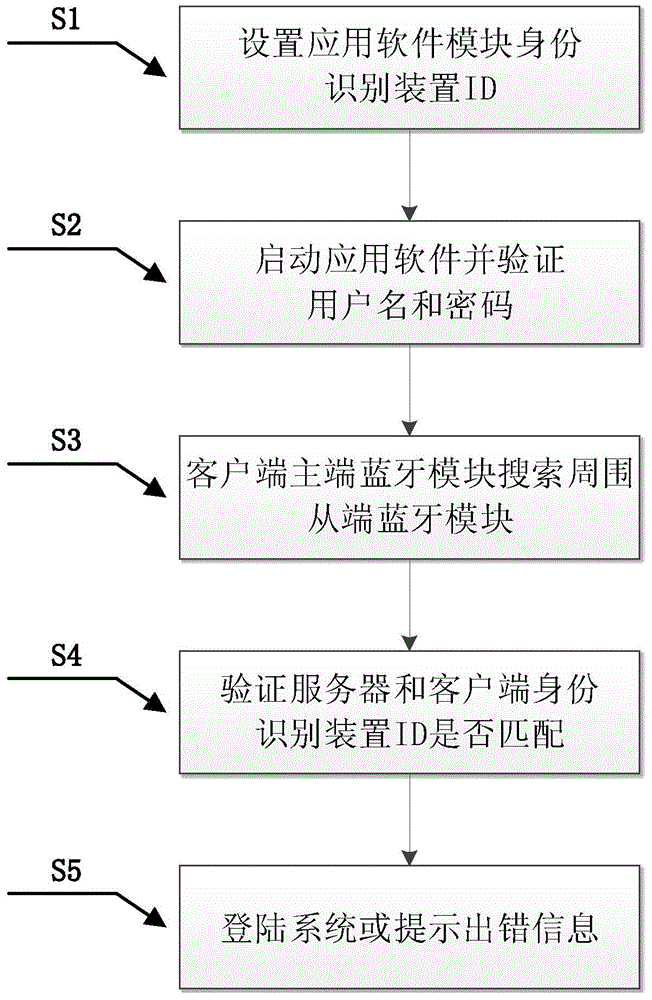

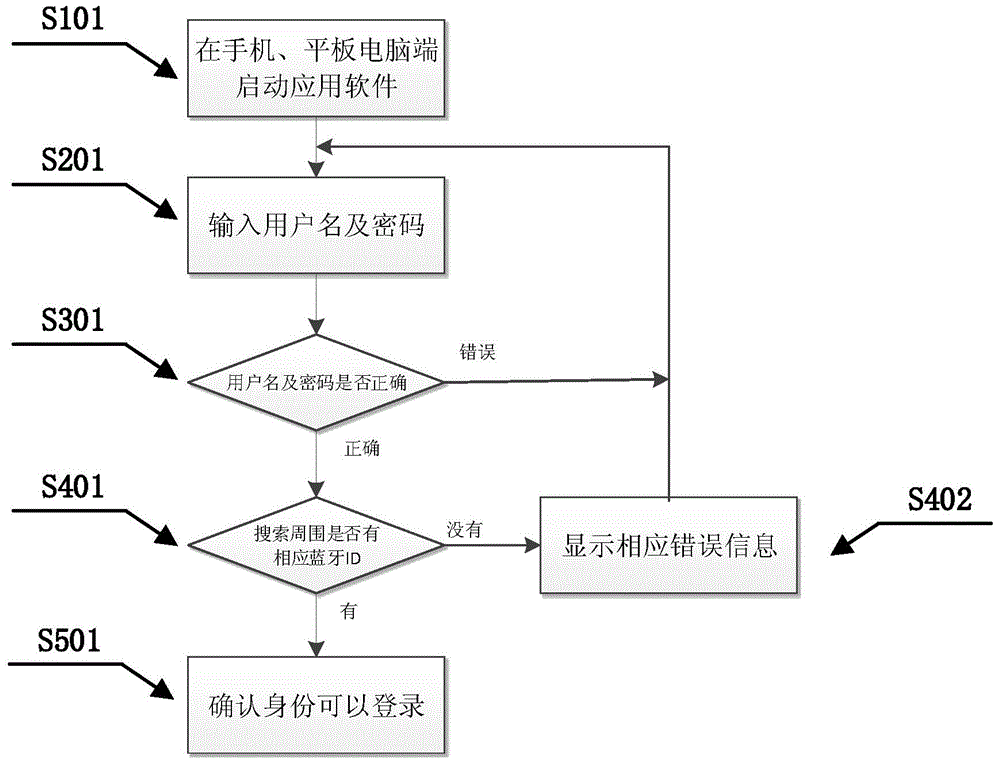

Identity recognition device and identity recognition method

InactiveCN104486296ASimple structureImprove robustnessTransmissionShort range communication servicePattern recognitionWireless transmission

The invention provides an identity recognition device and an identity recognition method. The device comprises a client module, a server module, an identity recognition module and a cloud service platform; bidirectional communication is performed between the client module and the server module through a wireless transmission mode; the bidirectional communication is performed between the identity recognition module and the server module through a wired or wireless transmission mode; the bidirectional communication is performed between the cloud service platform and the server module through a wired or wireless mode. According to the device, ID (identity) of an identity recognition device is set in an application software module, and is matched with a slave end Bluetooth module of the searched identity recognition device; on the premise that a user name and a password are verified, ID of the identity recognition device is further verified; the device is simple in structure and high in robustness; while the user name and the password of a client are verified, the client is also enabled to be located nearby the server module and the identity recognition module, and the effect of software and hardware double insurance of identity recognition is achieved.

Owner:郭岩

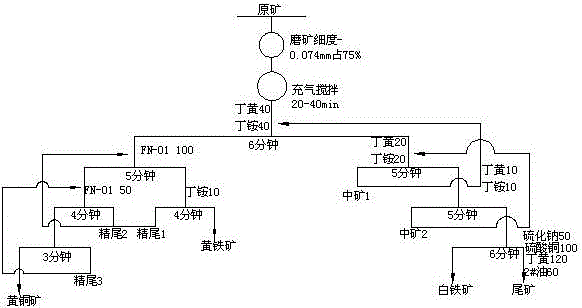

Method for separating chalcopyrite from marcasite and pyrites in copper and sulphur ores

The invention discloses a method for separating chalcopyrite from marcasite and pyrites in copper and sulphur ores, which comprises the following steps of: (1) carrying out crushing and grinding; (2) carrying out aerating agitation, i.e. regulating concentration of ore pulp to about 30 to 35 weight percent, placing the ore pulp into an agitator, and carrying out aerating agitation for 20 to 40min; (3) roughing to obtain rough concentrates and rougher tailings; (4) carrying out primary scavenging to obtain middlings 1 and primary scavenging tailings, and returning the middlings 1 to carry out roughing; (5) carrying out secondary scavenging to obtain middlings 2 and secondary scavenging tailings, and returning the middlings 2 to carry out primary scavenging; (6) carrying out copper tailing flotation to obtain the marcasite and total tailings; (7) carrying out primary concentration to obtain primary concentrated foam and primary concentrated tailings; (8) carrying out fine scavenging to obtain fine tailings 1 and the pyrites, and returning the fine tailings 1 to carry out primary concentration; (9) carrying out secondary concentration to obtain secondary concentrated foam and concentrated tailings 2, and returning the concentrated tailings 2 to carry out primary concentration; (10) tertiary concentration to obtain the marcasite and tailings 3, and returning the tailings 3 to carry out secondary concentration.

Owner:TONGLING NON FERROUS METAL GROUP CORP

Deep supercooled liquid oxygen filling and control system in low-temperature rocket launching site and method

ActiveCN112228765AQuality improvementNo need to consider load matchingVessel wallsPipeline systemsPositive pressureRocket launch

The invention discloses a deep supercooled liquid oxygen filling and control system in a low-temperature rocket launching site and a method. The system comprises a ground circulating liquid oxygen storage tank, a negative-pressure liquid nitrogen bath type heat exchanger and an on-rocket liquid oxygen storage tank. Before launching, saturated liquid nitrogen and low-temperature helium are combinedto precool the on-rocket storage tank in sequence, after the precooling requirement is met, a large-flow filling mode is adopted for filling, and the purpose of rapid filling is achieved; and a coldhelium technology is adopted to dynamically adjust the pressure of a rocket storage tank and maintain large supercooling of liquid oxygen temperature, and meanwhile, a cold helium recycling technologyis considered based on a cryogenic liquefaction separation method. According to the system and the method, the functions of deep supercooled acquisition and high-flow rapid filling of liquid oxygen,advanced falling of a filling system, micro-positive pressure adjustment and large supercooling degree maintenance of the deep supercooled liquid oxygen of the on-rocket storage tank, helium cyclic utilization and the like are realized, and effective reference can be provided for deep supercooling and filling processes and a control mode of the liquid oxygen in the low-temperature rocket launchingsite.

Owner:XI AN JIAOTONG UNIV

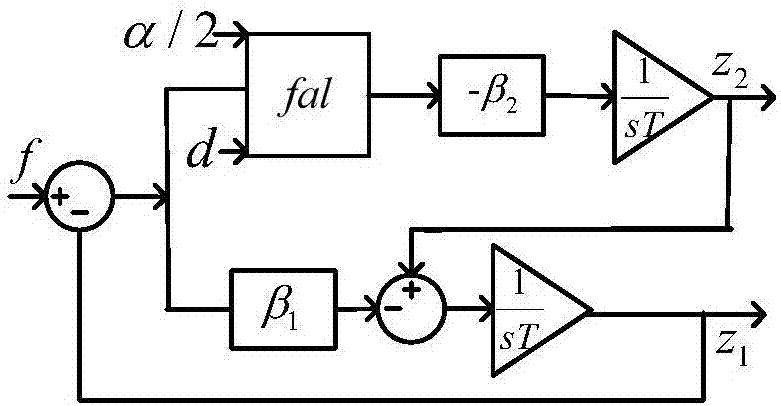

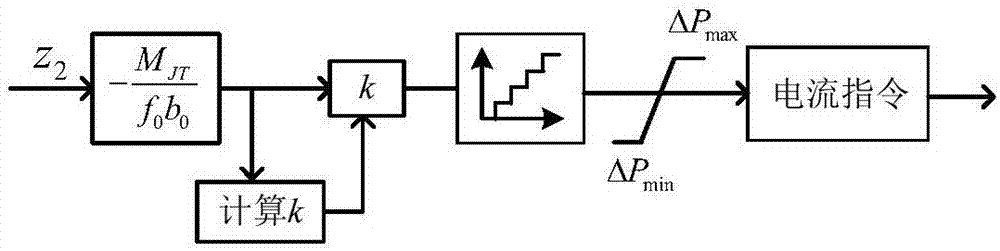

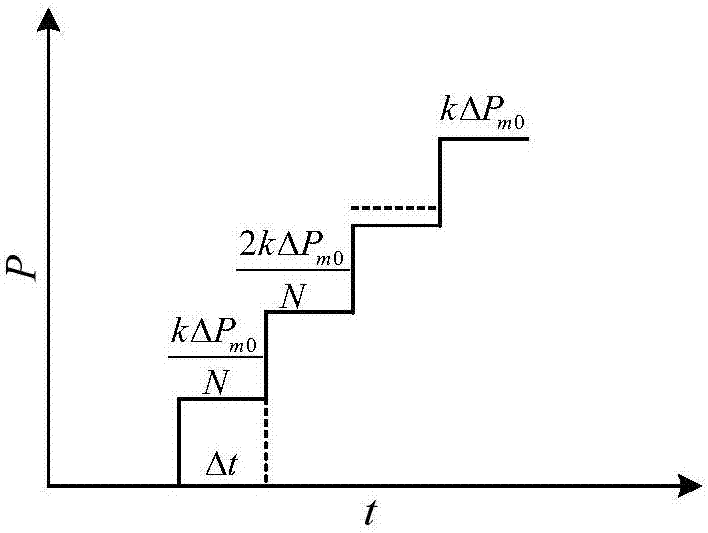

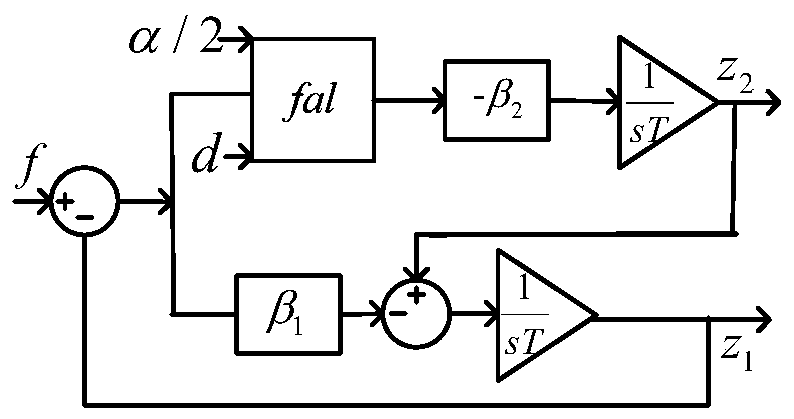

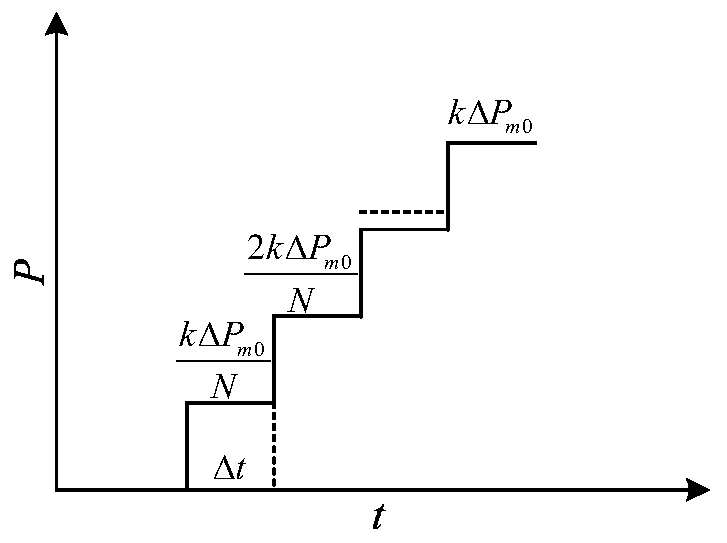

Adaptive HVDC emergency power support method

ActiveCN107294127AAccurate estimateShow validityElectric power transfer ac networkRestriction factorState observer

The invention provides a HVDC adaptive emergency power support method based on real-time estimation of unbalanced power in an AC-DC interconnected electric power system region in order to solve the problem of power angle oscillation of a generator in the fault or disturbance condition of an AC-DC interconnected electric power system. The method includes: establishing an extended state observer of unbalanced power in the region in the system disturbance, and setting parameters of the observer to realize real-time and accurate estimation of the unbalanced power; analyzing direct current emergency power support restriction factors, optimizing an emergency power support amount, and forming the final power support amount; and finally achieving the goal of power support based on a power support stepped increasing principle. According to the method, compared with a conventional fixed-value emergency power support method, the unbalanced power of the system can be estimated in real time so that the power support amount is adjusted in real time, and the goal of dynamic and optimal power support can be achieved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

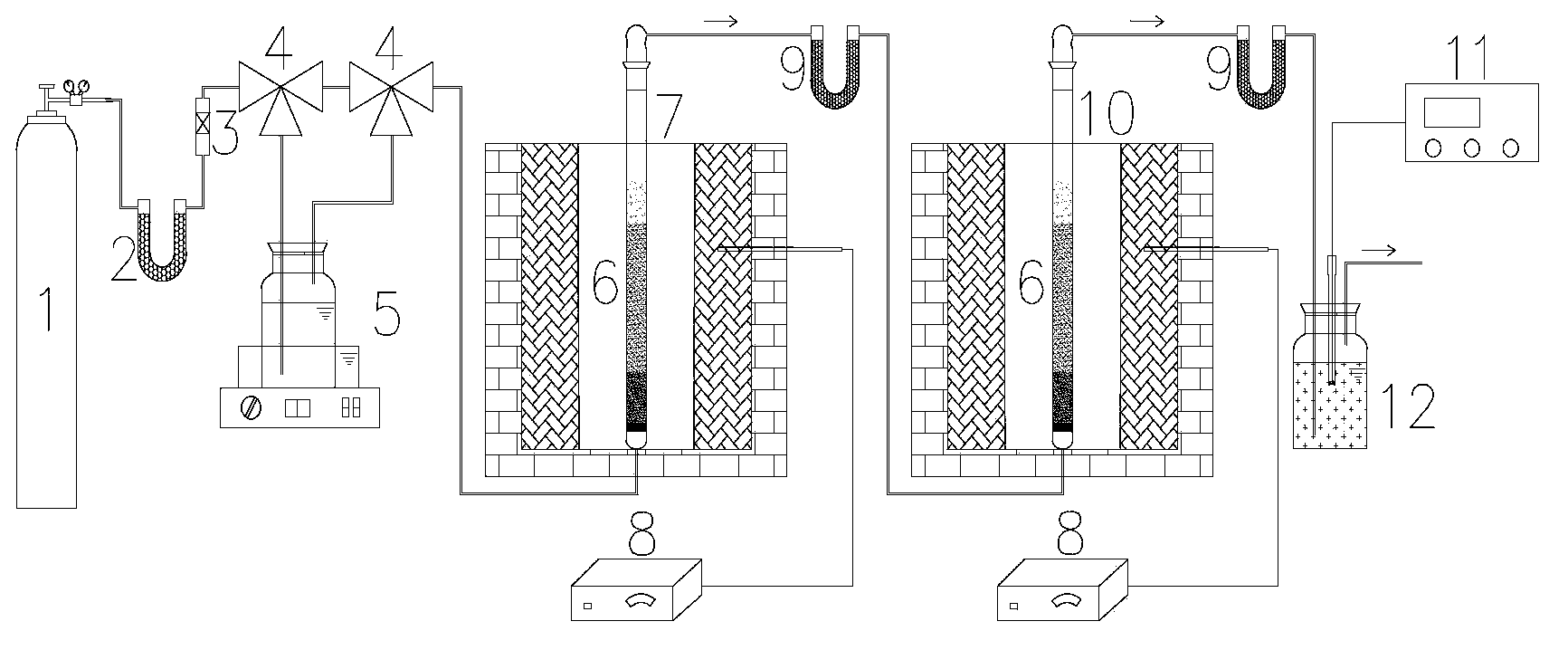

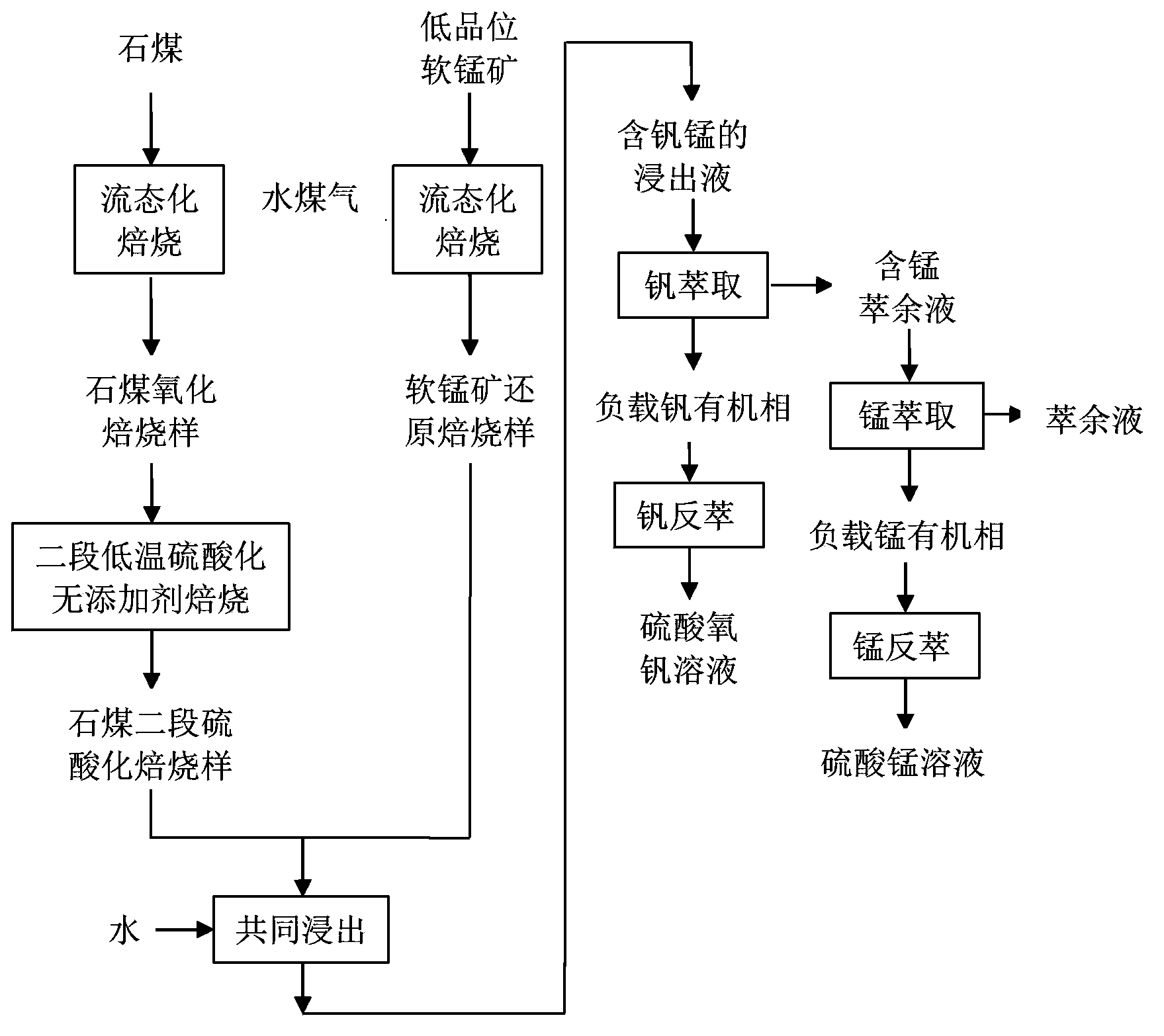

Method for recovering vanadium and manganese by using stone coal and low-grade pyrolusite together

InactiveCN103436714AImprove recycling efficiencyRecycling is fully effectiveProcess efficiency improvementPyrolusiteMass ratio

The invention discloses a method for recovering vanadium and manganese by using stone coal and low-grade pyrolusite together, and belongs to the field of mineral metallurgy. The method comprises the following steps that (1), the stone coal and the low-grade pyrolusite at a mass ratio of (1-10):1 are subjected to fluidization roasting, and generated water gas is used for reduction roasting of the low-grade pyrolusite; (2), a stone coal fluidization oxidizing roasting sample is added to sulfuric acid and subjected to low-temperature sulfating additive-free roasting continuously; (3), a stone coal sulfating roasting sample and a pyrolusite fluidization reduction roasting sample are leached together to extract vanadium and manganese; and (4), a vanadium and manganese extract is subjected to asynchronous extraction separation for recovering vanadium and manganese, and pure vanadyl sulfate and manganese sulfate solutions are obtained, wherein an extraction rate of vanadium is greater than 98%, a reextraction rate of vanadium is 100%, an extraction rate of manganese is greater than 95%, and a reextraction rate of manganese can reach 100%. The method can sufficiently and effectively recover vanadium and manganese resources in the stone coal and the low-grade pyrolusite, is simple in technology, wide in application scope, low in acid consumption and energy consumption, and high in vanadium and manganese recovery efficiency, and does not pollute an environment.

Owner:UNIV OF SCI & TECH BEIJING

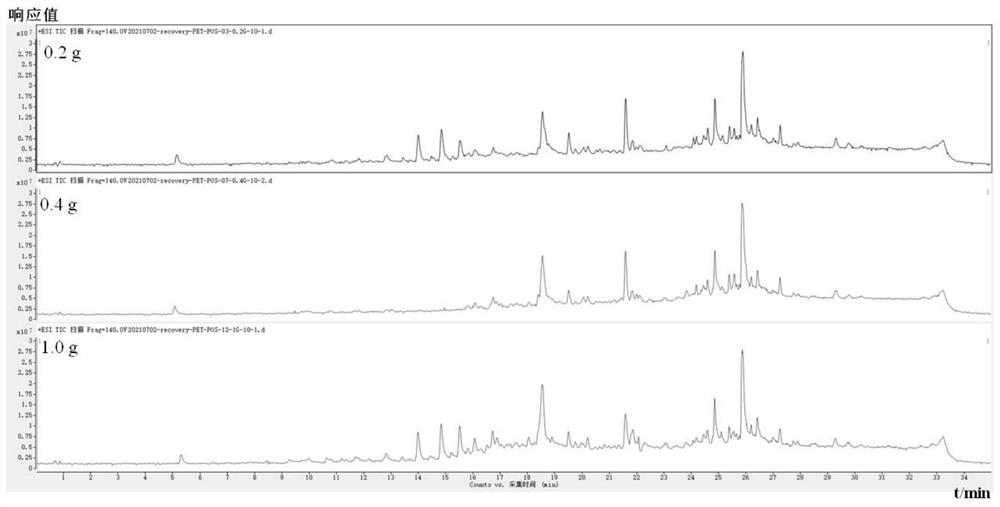

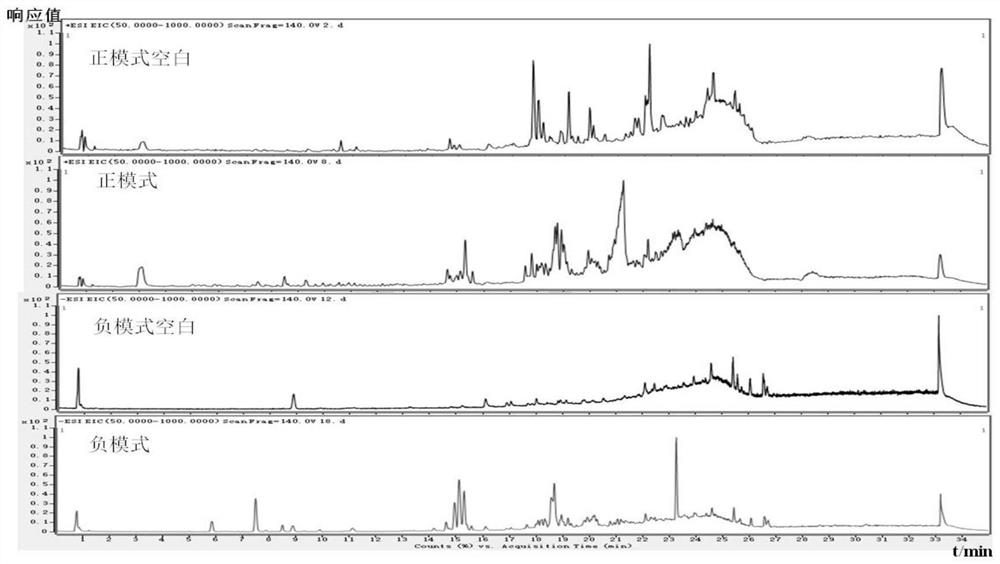

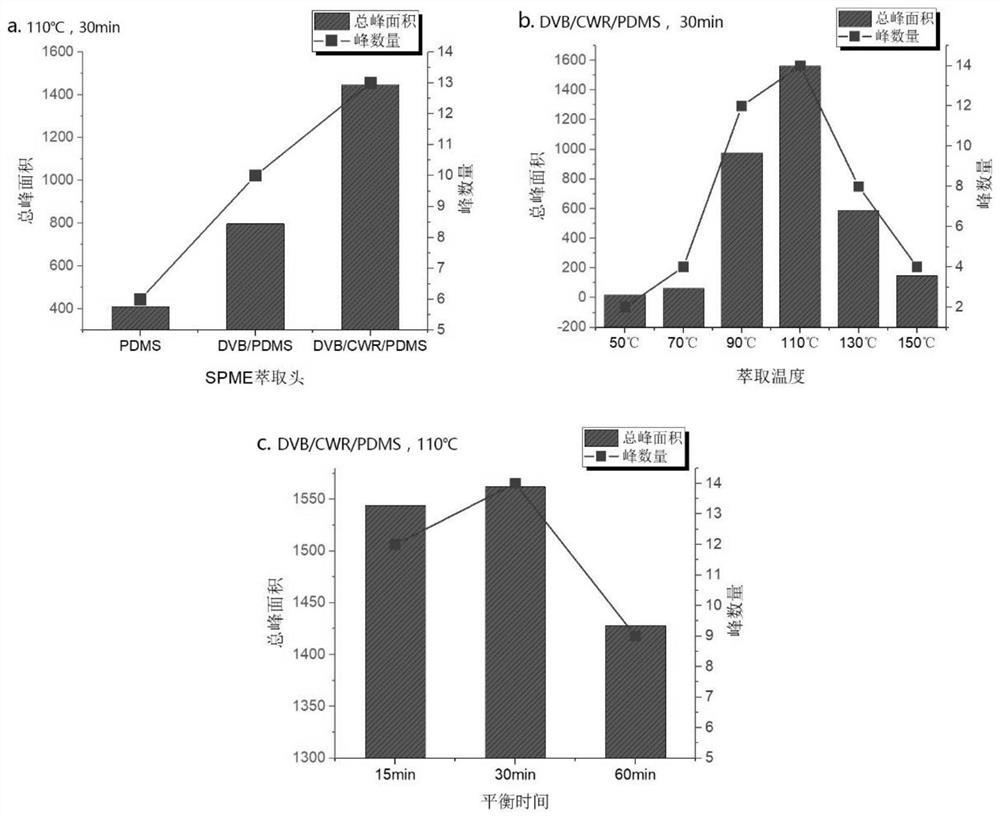

High-throughput non-targeted screening method for pollutants in regenerated PET material for food contact

PendingCN113899837AImprove throughputImprove accuracyComponent separationPolyethylene terephthalate glycolResolution (mass spectrometry)

The invention discloses a high-throughput non-targeted screening method for pollutants in a regenerated PET (Polyethylene Terephthalate) material for food contact. Ultra-high performance liquid chromatography-quadrupole time-of-flight high-resolution mass spectrometry (UPLC-QTOF-MS), SPME-GC x GC-QTOF-MS and GC x GC-QTOF-MS to screen the pollutants in recycled PET bottle chips for food contact, wherein the pollutants comprise non-volatile organic pollutants, volatile organic pollutants and semi-volatile organic pollutants. The method has the advantages of high throughput, high accuracy, rapidness, sensitivity, good selectivity and the like.

Owner:TECH CENT OF GUANGZHOU CUSTOMS

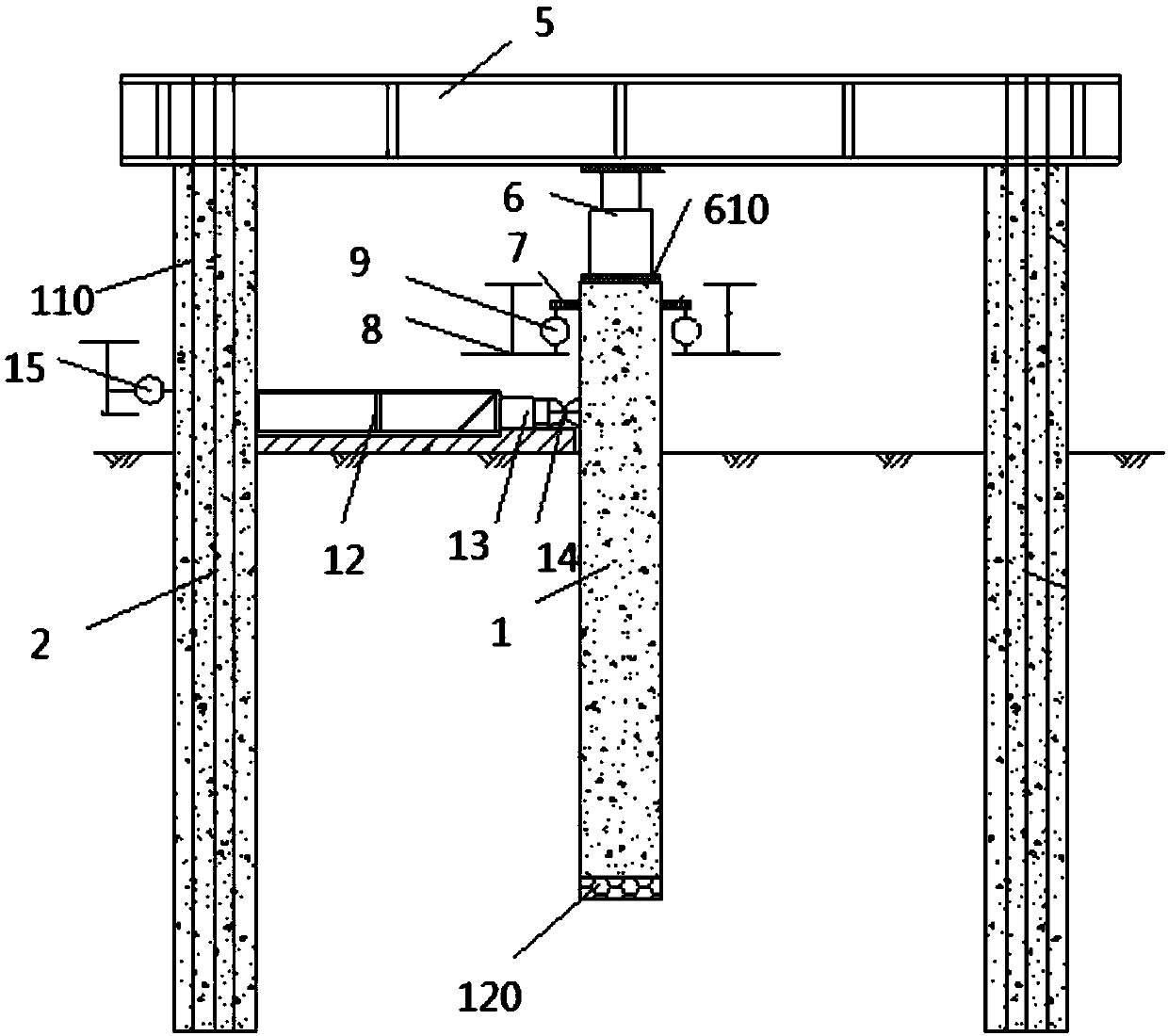

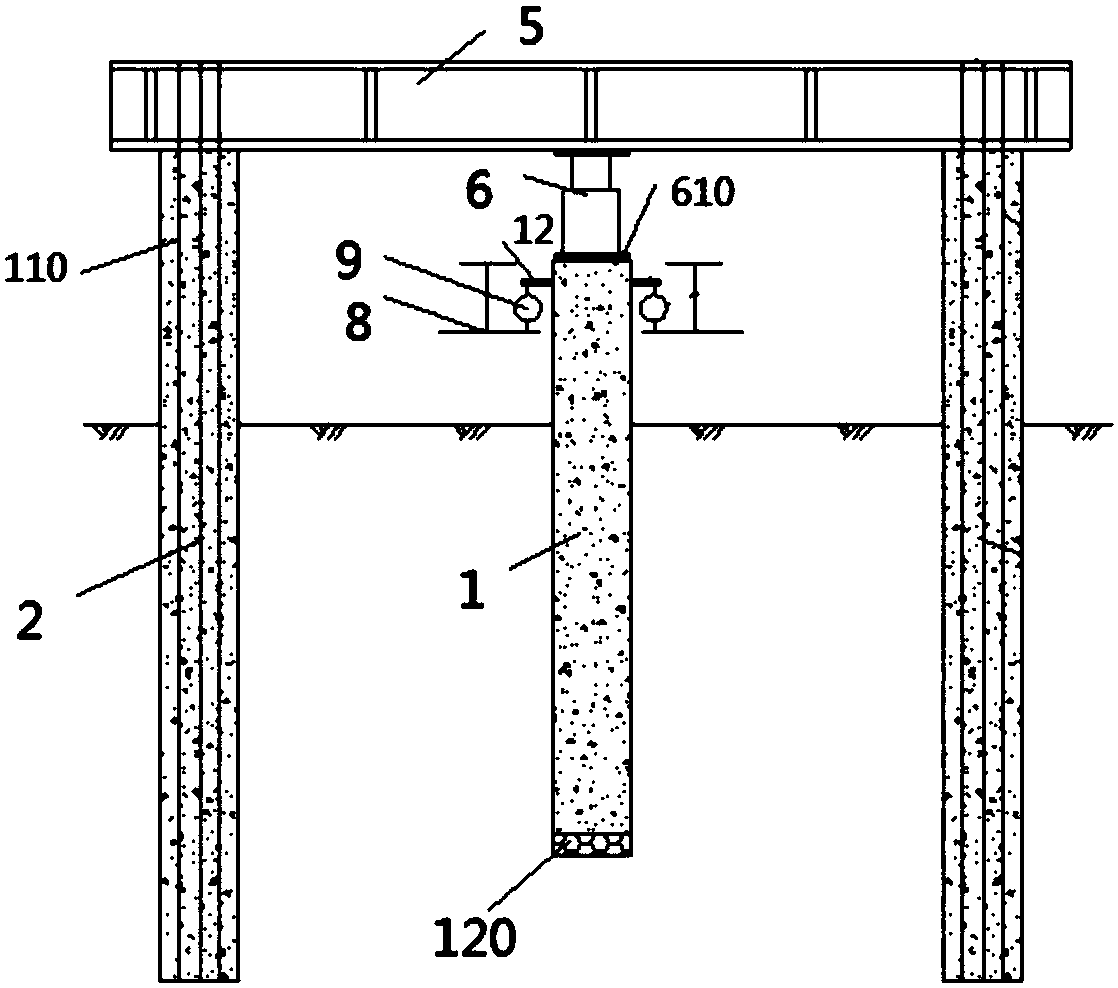

Field test method of influence on vertical bearing capacity of pile foundation by horizontal cyclic load

ActiveCN107938722AEliminate residual deformationStrong reference valueFoundation testingField testsCoral reef

Owner:CCCC SECOND HARBOR ENG +1

Experiment furnace and experiment method for representing concrete high-temperature burst degree

InactiveCN107907571AEasy to testThe test result is accurateMaterial flaws investigationThermocoupleMaterials science

The invention belongs to the technical field of experiment furnaces, and particularly relates to an experiment furnace and an experiment method for representing concrete high-temperature burst degree.The experiment furnace comprises an electric furnace and a test piece placement device, the electric furnace is composed of an outer shell, an inner bin and an electric furnace temperature controller, the inner bin is formed by building two layers of refractory bricks, heating elements are arranged between the refractory bricks, the temperature controller is movably connected with the outer shell, and a furnace door is arranged right ahead the outer shell; the test piece placement device is composed of a tray, a connection rod, a motor, a pressure sensor and a second thermocouple, the motor is arranged at the bottom of the inner bin, an output shaft of the motor is connected with the lower end of the connection rod, the upper end of the connection rod is movably connected with the tray, and the pressure sensor is arranged in a cavity between the outer shell and the inner bin.

Owner:SHANXI UNIV

Method for comprehensively recovering copper and sulfur from deep-sea high-sulfur and high-copper ores and application of the method

The invention discloses a method for comprehensively recovering copper and sulfur from deep-sea high-sulfur and high-copper ores and application of the method. The method comprises the following steps: (1) grinding raw ores, and filtering and dehydrating the raw ores; (2) diluting and roughing the feed of the copper separation operation; (3) scavenging the copper roughing tailings for three times;(4) combining copper roughing with copper scavenging foam and finely selecting; (5) performing secondary selection of copper selection foam; (6) concentrating and dehydrating the copper scavenging tailings; (7) carrying out sulfur concentration, underflow size mixing and roughing; (8) scavenging sulfur roughing tailings; and (9) performing sulfur roughing and sulfur scavenging foam concentration.The method has the beneficial effects that filtration dehydration and concentration dehydration are performed in sequence; acid water and high-alkali tailing water which are respectively removed arerespectively subjected to sulfur separation and copper separation in a grafting and transplanting manner; the technical problems that the pH value cannot be effectively adjusted by adopting a traditional agent in deep sea high-sulfur high-copper ore, interference of seawater ions on flotation operation cannot be avoided by adopting a traditional technological process, and effective separation andrecovery of copper ore and sulfur ore cannot be guaranteed are solved.

Owner:安徽铜冠产业技术研究院有限责任公司

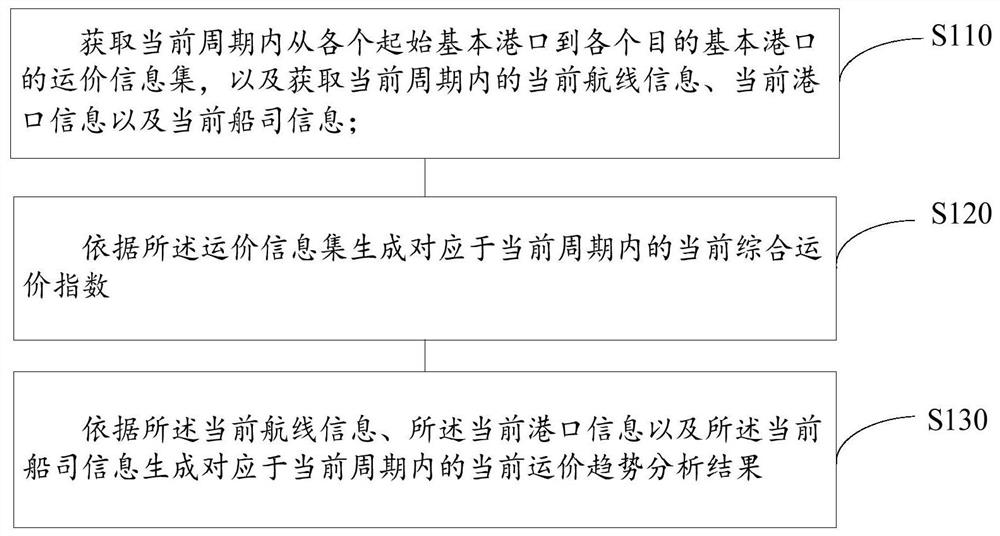

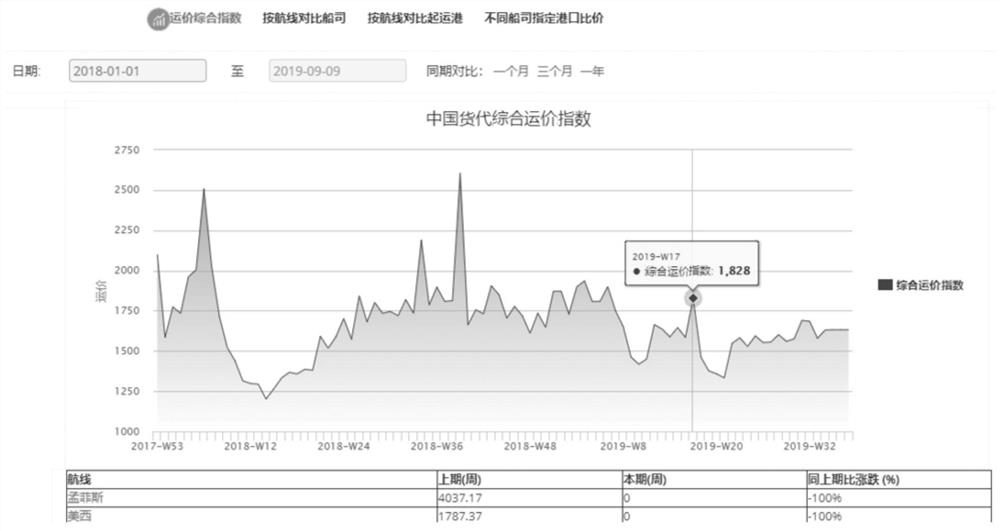

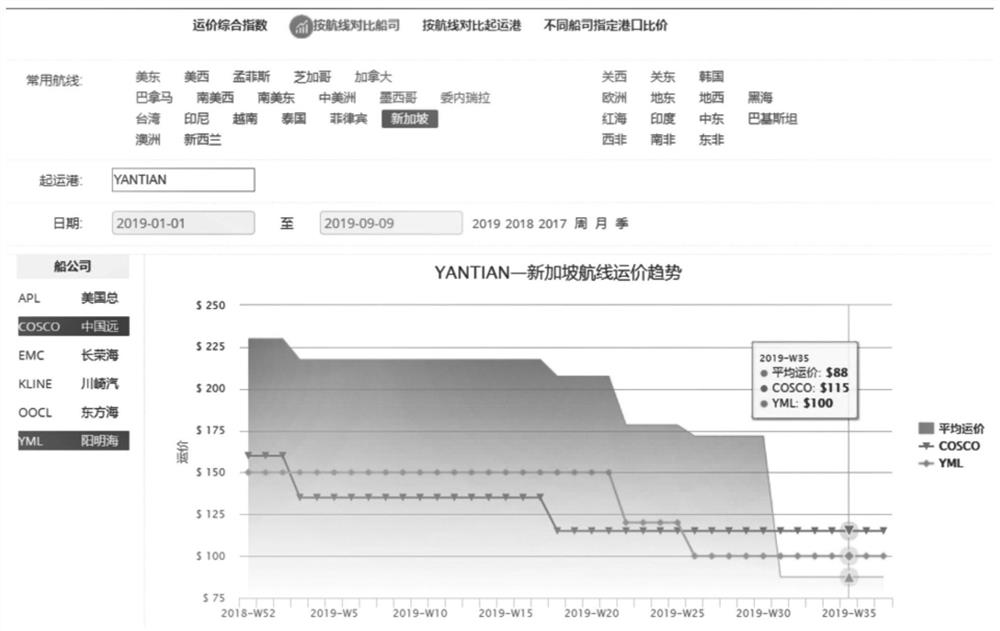

International shipping price trend analysis method and device

InactiveCN112651687AAccurate predictionEasy to controlLogisticsMarket data gatheringInternational shippingTrend analysis

The invention provides an international shipping price trend analysis method and device, and the method comprises the steps: obtaining a shipping price information set from each starting basic port to each target basic port in a current period, and obtaining the current route information, current port information and current ship information in the current period; generating a current comprehensive freight rate index corresponding to the current period according to the freight rate information set; and generating a current freight rate trend analysis result corresponding to the current period according to the current route information, the current port information and the current ship company information. By calculating and analyzing the data in the current period, the analyzed result has high reference value on one hand and high timeliness on the other hand, and can be directly used for market pre-measures and formulating future prices, so that the profit of the shipping order is effectively and accurately controlled, the risk caused by human factors is eliminated, and the market can be accurately predicted and controlled.

Owner:CHINATRANS INT LTD

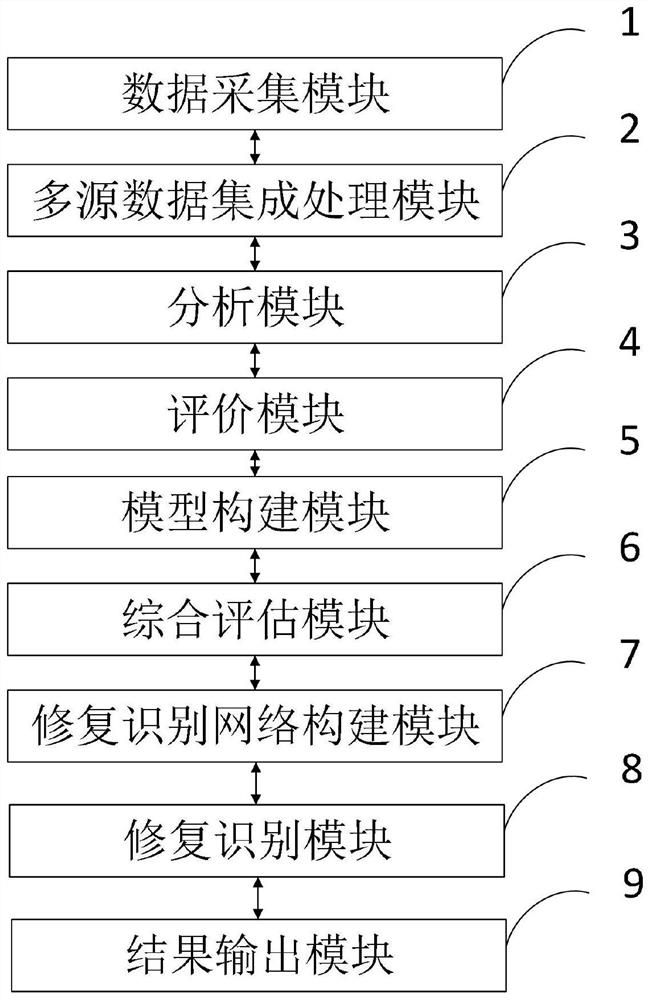

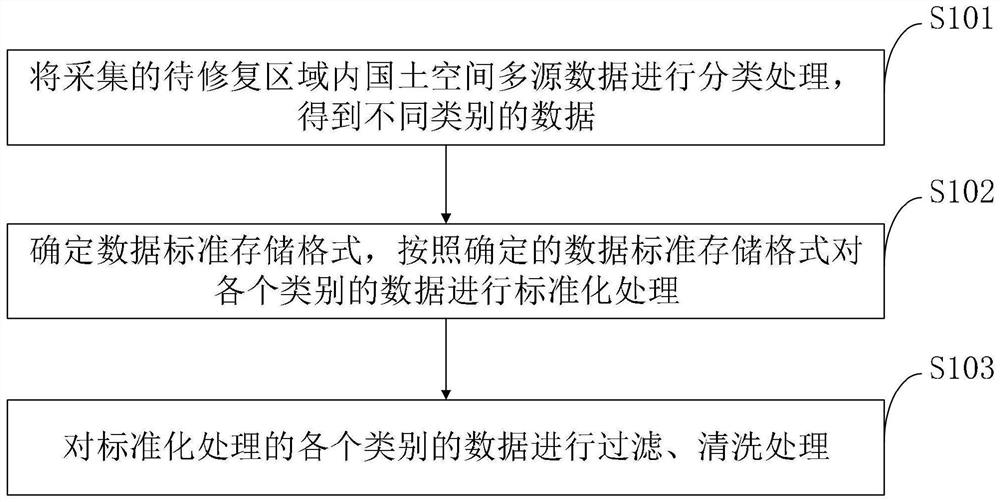

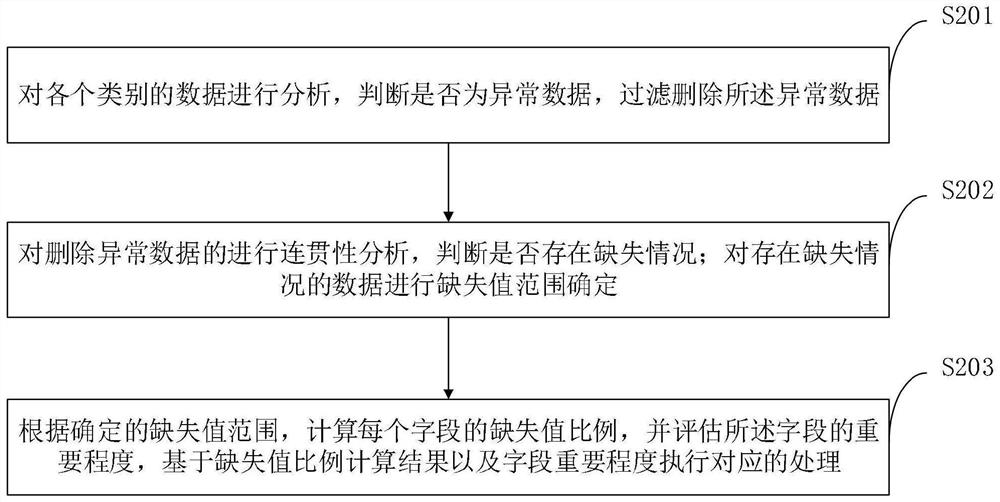

Territorial space ecological restoration key area identification system

ActiveCN114386816AStrong referenceStrong reference valueResourcesEnvironmental resource managementEcological environment

The invention belongs to the technical field of ecological restoration, and discloses a land space ecological restoration key area identification system, which comprises a data acquisition module, a multi-source data integrated processing module, an analysis module, an evaluation module, a model construction module, a comprehensive evaluation module, a restoration identification network construction module, a restoration identification module and a result output module. The method is based on an element-pattern-process-service cascade framework of territorial space, emphasizes integrated measurement and evaluation of mountain, water, forest, field, lake and grass elements, layouts an ecological safety network and maintains ecological safety, and further realizes a multi-scale and multi-level identification technology of an ecological restoration key area. The method can be widely applied to territorial space ecological restoration scheme making and planning, and particularly has high reference significance and reference value in the aspects of regional society-ecology coupling relation and mutual feedback mechanism analysis, ecological environment conditions, ecological function importance and vulnerability evaluation research, ecological restoration key region recognition and the like.

Owner:SICHUAN AGRI UNIV

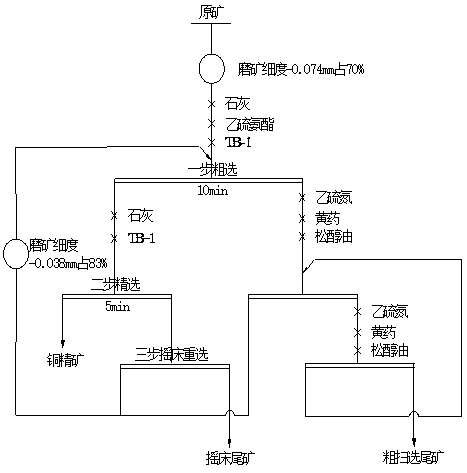

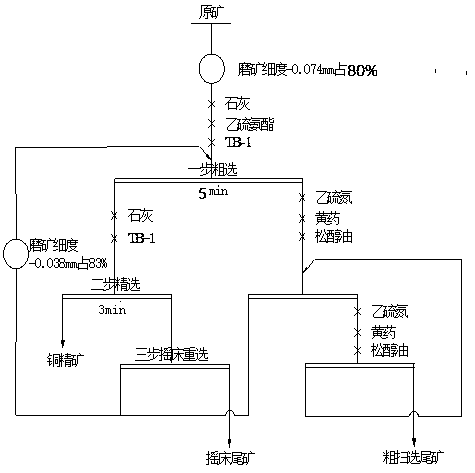

Process method for separating talc and chalcopyrite through three-step method and collecting agent used in process method

ActiveCN111570077AAvoid inclusionsEfficient separationFlotationWet separationThiocarbamateChalcopyrite

The invention provides a process method for separating talc and chalcopyrite through a three-step method and a collecting agent used in the process method. The method comprises the steps of carrying out ore grinding, carrying out first-step roughing, carrying out second-step concentration, and carrying out third-step table reselection and regrinding operation. The process method aims at separationof the talc and the chalcopyrite, the preferential copper separation technological process is adopted for the first time under the condition that a special-effect talc inhibitor is not added, and effective separation of the talc and the chalcopyrite is achieved. According to the process method, the collecting agent TB-1 formed by mixing isobutyl xanthate propionitrile ester, N-allyl-O-alkyl thiocarbamate and Spans type sorbitan ester is adopted to strengthen flotation of the chalcopyrite, the thickness of a foam layer is adjusted through the defoaming performance of the collecting agent TB-1,and the relative floating speed of the talc and the chalcopyrite is changed; and the flotation and reselection combined technological process is adopted, and effective separation of talc and chalcopyrite is achieved through three steps. The flotation reagent adopted in the process method has the characteristics of low toxicity or no toxicity, environment friendliness, good effect and the like, and an environment-friendly and high-efficiency process method for separating the talc and the chalcopyrite is provided.

Owner:安徽铜冠产业技术研究院有限责任公司

Method for breeding river crabs and crayfishes in same pond

PendingCN113455432AImprove economic efficiencyStrong reference and reference valueClimate change adaptationPisciculture and aquariaEnvironmental geologyShrimp culture

The invention provides a method for breeding river crabs and crayfishes in the same pond. The method comprises the breeding processes of pond preparation, larval crab stocking, crayfish with egg stocking, margarya melanoide transferring, first-time fishing and second-time fishing. According to the method, crayfish breeding is introduced into a river crab breeding pond firstly, the problems of time difference and spatial distribution between the river crabs and the crayfishes are successfully solved, the yield of the river crabs and the yield of the crayfishes are not reduced, the economic benefit is high, and the reference value is high. According to the method, engineering transformation does not need to be carried out on an existing river crab breeding pond, the breeding and fishing technology of the crayfishes with the eggs is introduced in good time, and yield-increasing breeding of the crayfishes in one season is successfully achieved within the time period from April to August.

Owner:FRESHWATER FISHERIES RES INSITUTE OF JIANGSUPROVINCE +2

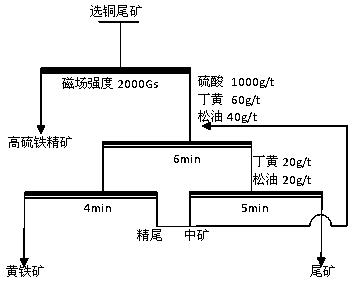

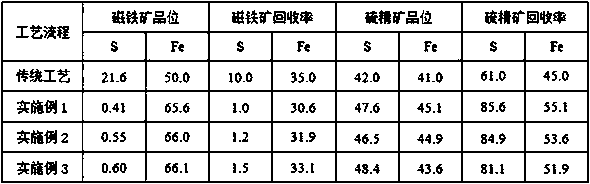

Method for recycling magnetite, monoclinic pyrrhotite, hexagonal pyrrhotite and pyrite step by step

ActiveCN108745625AQuality improvementSolve technical problems such as low gradeFlotationMagnetic separationSocial benefitsEconomic benefits

The invention discloses a method for recycling magnetite, monoclinic pyrrhotite, hexagonal pyrrhotite and pyrite step by step. The method comprises the following steps of 1, magnetic separation, 2, magnetic concentrate flotation, 3, pyrite roughing, 4, pyrite scavenging, 5, pyrite precise separation, 6, inoculation magnetic separation and 7, magnetic concentrate flotation. The method has the beneficial effects that the technical problem that the magnetite and the monoclinic pyrrhotite are approximate in density and magnetism, the sulfur content of the magnetite is high, the hexagonal pyrrhotite is prone to argillization and oxidization, and the hexagonal pyrrhotite and gangue mineral are approximate in floatability, so that the sulfur concentrate grade is not high is solved. The method hasimportant significance to increasing of the economic benefits of an enterprise and social benefits.

Owner:安徽铜冠产业技术研究院有限责任公司

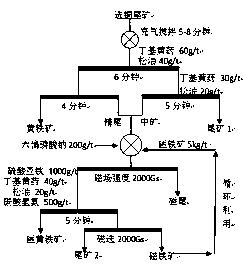

Method for recycling high-quality iron ore from high-sulphur-content iron pyrite

InactiveCN106475217ASolve the problems of low grade and high iron loss rate in sulfur concentrateEasy to separateFlotationWet separationIronstoneSulfur

The invention discloses a method for recycling high-quality iron ore from high-sulphur-content iron pyrite. The method comprises the following steps that 1, raw ore is crushed and ground to be of 200-300 meshes, agentia A is added, and grinding continues to be carried out; 2, water is added for adjusting the concentration of flotation slurry to be 36-37%, and a collecting agent B is added; 3, 300-800 g / t carbon powder and lime water are added for adjusting the pH of the ore slurry to be 12.3 or more, stirring is carried out for 5-10 min, and the ore slurry is fed into a flotation machine for flotation for 4-8 min; 4, grinding is carried out again, 100-300 g / t carbon powder is added for grinding through a ball mill, and the size fraction of the ground ore fineness being -0.044 mm accounts for 80-90%; and 5, the material is fed into a flotation machine for flotation for 3-6 min, and therefore the high-quality iron ore is obtained. The iron concentrate grade and recycling rate are high, and sulphur is well recycled.

Owner:HUNAN HENGGUANG CHEM

An adaptive hvdc emergency power support method

ActiveCN107294127BAccurate estimateShow validityElectric power transfer ac networkElectric power systemControl theory

The invention provides a HVDC adaptive emergency power support method based on real-time estimation of unbalanced power in an AC-DC interconnected electric power system region in order to solve the problem of power angle oscillation of a generator in the fault or disturbance condition of an AC-DC interconnected electric power system. The method includes: establishing an extended state observer of unbalanced power in the region in the system disturbance, and setting parameters of the observer to realize real-time and accurate estimation of the unbalanced power; analyzing direct current emergency power support restriction factors, optimizing an emergency power support amount, and forming the final power support amount; and finally achieving the goal of power support based on a power support stepped increasing principle. According to the method, compared with a conventional fixed-value emergency power support method, the unbalanced power of the system can be estimated in real time so that the power support amount is adjusted in real time, and the goal of dynamic and optimal power support can be achieved.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

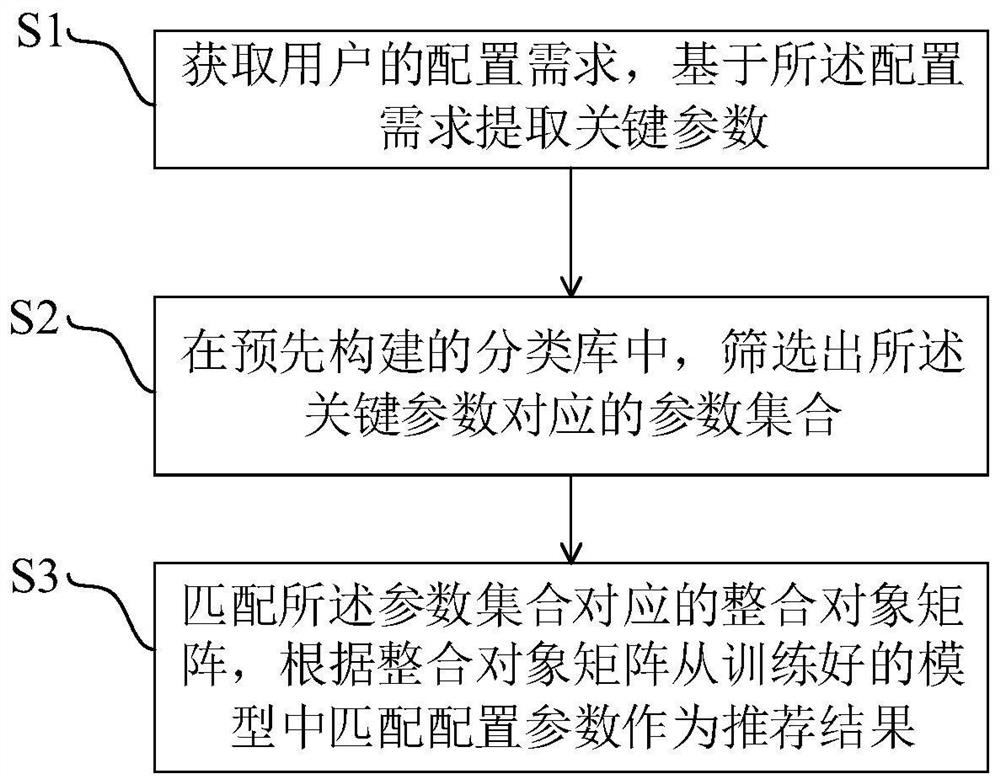

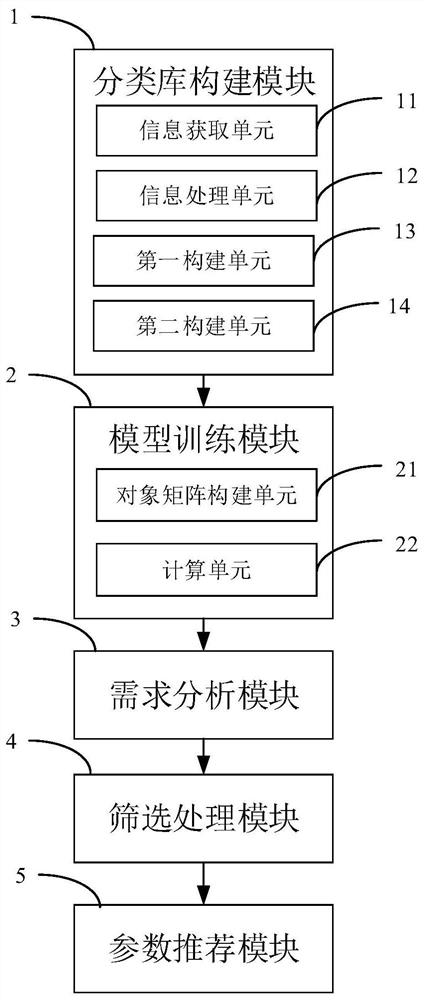

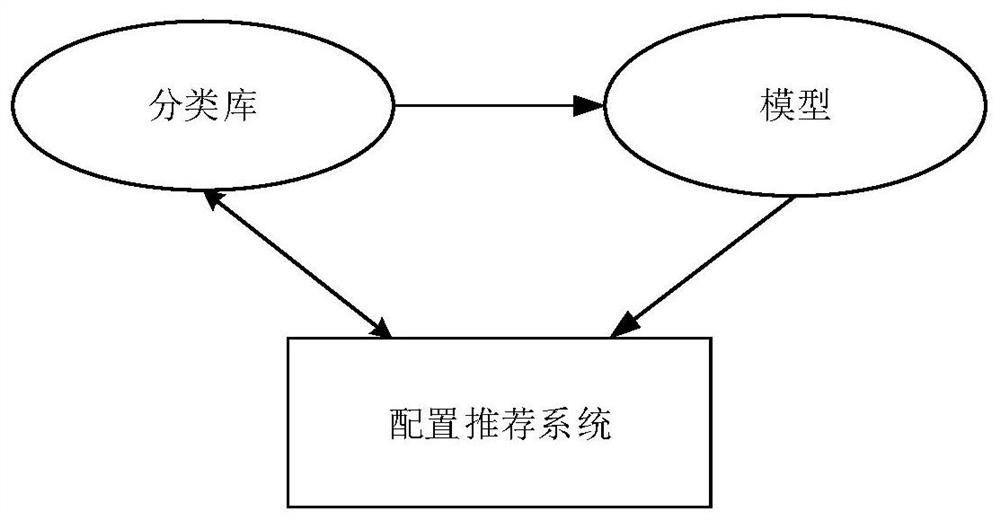

Configuration recommendation method, system and device and computer storage medium

ActiveCN112000389ASave configuration timeImprove learning efficiencyProgram loading/initiatingUser needsEngineering

The invention provides a configuration recommendation method, system and device and a computer storage medium, and the method comprises the steps: obtaining a configuration demand of a user, and extracting key parameters based on the configuration demand; screening out a parameter set corresponding to the key parameters in a pre-constructed classification library; and matching an integrated objectmatrix corresponding to the parameter set, and matching configuration parameters from a trained model according to the integrated object matrix to serve as a recommendation result. According to the invention, the existing configuration data is collected and analyzed, the classification library is formed, the parameters in the classification library are trained, the corresponding configuration parameters under different parameter sets are obtained and written into the model, and when the user is docked, the optimal configuration parameters are obtained from the model by obtaining user requirements and screening based on the classification library such that the configuration time is greatly saved, and the learning and working efficiency is improved.

Owner:INSPUR SUZHOU INTELLIGENT TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com