Method for recycling magnetite, monoclinic pyrrhotite, hexagonal pyrrhotite and pyrite step by step

A technology of pyrrhotite and pyrite, which is applied in the field of mineral processing, can solve the problems of low added value, resource waste, mudification, etc., achieve the effect of magnetic enhancement, improve the economic benefits of enterprises, and solve the effects of high prices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

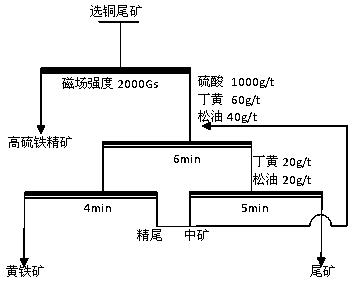

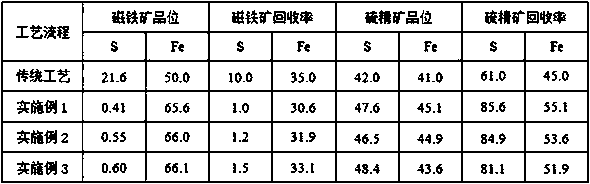

[0027] Embodiment 1: the method for reclaiming magnetite, monoclinic pyrrhotite, hexagonal pyrrhotite and pyrite step by step, it may further comprise the steps:

[0028] (1) Magnetic separation: adjust the concentration of copper-separated tailings to 25%, and send them to a magnetic separator for magnetic separation at a magnetic field strength of 1800Gs to obtain magnetic concentrates and magnetic separation tailings. Magnetic concentrates include magnetite and single Plagiopyrhotite, magnetic separation tailings include pyrite and hexagonal pyrrhotite;

[0029] (2) Magnetic concentrate flotation: adjust the concentration of magnetic concentrate to 25%, add 500g / t oxalic acid and ferrous sulfate each, stir for 5min; add 20g / t butyl sodium xanthate and 20 g / t pine oil , stirring for 2 minutes, and flotation for 5 minutes to obtain flotation concentrate and flotation tailings, the flotation concentrate is monoclinic pyrrhotite, and the flotation tailings is magnetite;

[003...

Embodiment 2

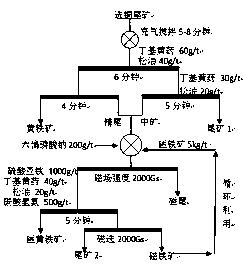

[0035] Embodiment 2: the method for reclaiming magnetite, monoclinic pyrrhotite, hexagonal pyrrhotite and pyrite step by step, it may further comprise the steps:

[0036] (1) Magnetic separation: Adjust the concentration of copper-separated tailings to 28%, and send them to a magnetic separator for magnetic separation at a magnetic field strength of 2000Gs to obtain magnetic concentrates and magnetic separation tailings. Magnetic concentrates include magnetite and single Plagiopyrhotite, magnetic separation tailings include pyrite and hexagonal pyrrhotite;

[0037] (2) Magnetic concentrate flotation: adjust the concentration of magnetic concentrate to 28%, add oxalic acid and ferrous sulfate 500g / t each, stir for 5min; add collector 25g / t and foaming agent 25 g / t, Stir for 2.5 minutes, and float for 7 minutes to obtain flotation concentrate and flotation tailings. The flotation concentrate is monoclinic pyrrhotite, and the flotation tailings is magnetite;

[0038] (3) Rough s...

Embodiment 3

[0043] Embodiment 3: the method for reclaiming magnetite, monoclinic pyrrhotite, hexagonal pyrrhotite and pyrite step by step, it may further comprise the steps:

[0044] (1) Magnetic separation: Adjust the concentration of copper-separated tailings to 30%, and send them to a magnetic separator for magnetic separation at a magnetic field strength of 2200Gs to obtain magnetic concentrates and magnetic separation tailings. Magnetic concentrates include magnetite and single Plagiopyrhotite, magnetic separation tailings include pyrite and hexagonal pyrrhotite;

[0045] (2) Magnetic concentrate flotation: adjust the concentration of magnetic concentrate to 30%, add oxalic acid and ferrous sulfate 500g / t each, stir for 5min; add collector 30g / t and foaming agent 30 g / t, Stir for 3 minutes, and float for 8 minutes to obtain flotation concentrate and flotation tailings. The flotation concentrate is monoclinic pyrrhotite, and the flotation tailings is magnetite;

[0046] (3) Rough sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com