SCADA data-based yaw control parameter optimization method for wind generation set

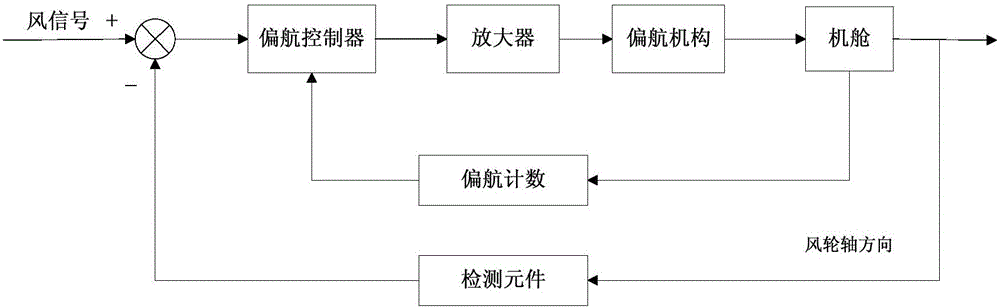

A technology of yaw control and wind turbines, which is applied in the direction of engine control parameters, wind engine control, wind power generation, etc., and can solve single problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

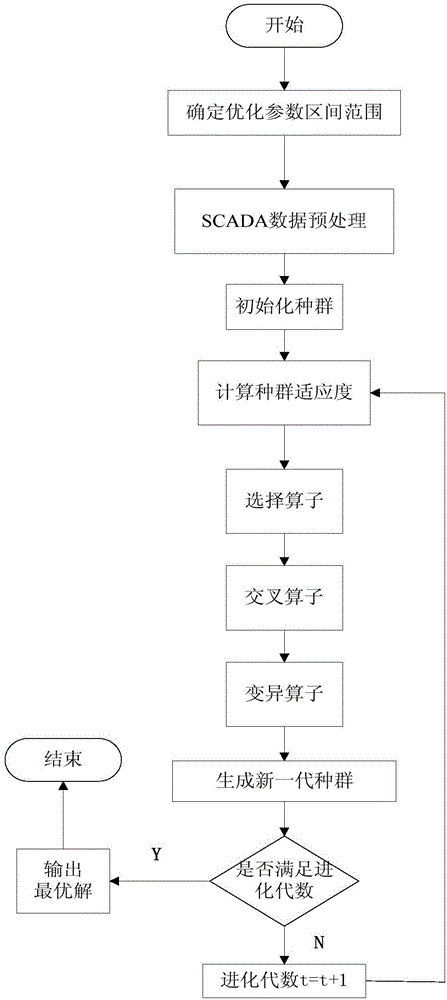

[0061] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0062] The present invention proposes a method for optimizing the yaw control parameters of wind turbines based on SCADA data, the steps of which are as follows: figure 2 As shown, the specific implementation steps are described as follows:

[0063] Step 1: Determine the parameter optimization interval

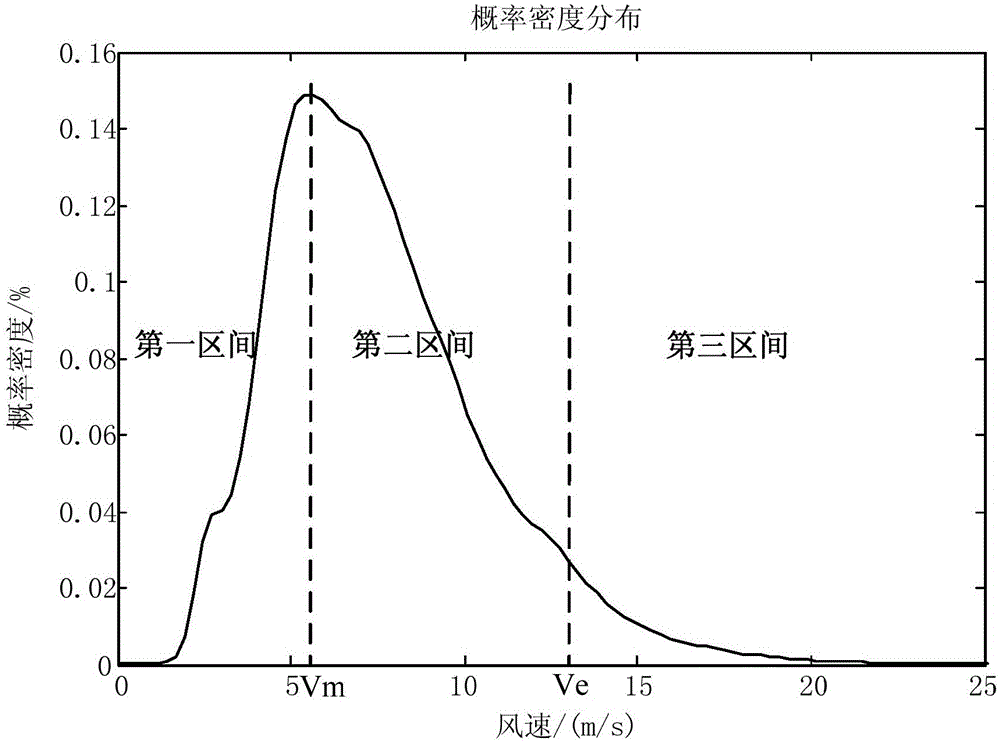

[0064] At present, wind farms of the same type generally specify the same yaw deviation threshold and delay time, and the wind speed partition boundary is generally a certain empirical wind speed value or rated wind speed value, and there is no unified standard. The present invention obtains the wind speed probability distribution curve based on the SCADA data of a single unit, and identifies the wind speed V corresponding to the "peak value" of the probability curve. m , with V m The rated wind speed V e The following wind speed range is divided into 2 ranges, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com