Experiment furnace and experiment method for representing concrete high-temperature burst degree

A high-temperature blasting and concrete technology is applied in the field of test furnaces to achieve the effects of convenient operation, strong reference value and reduced work intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

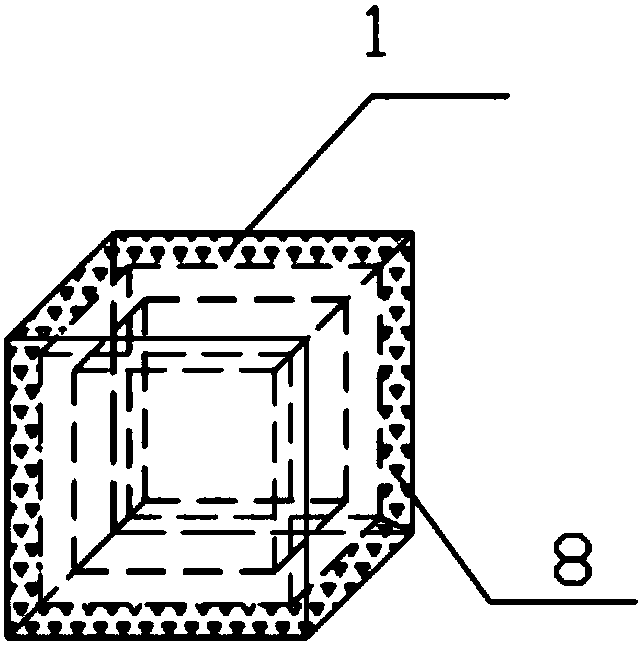

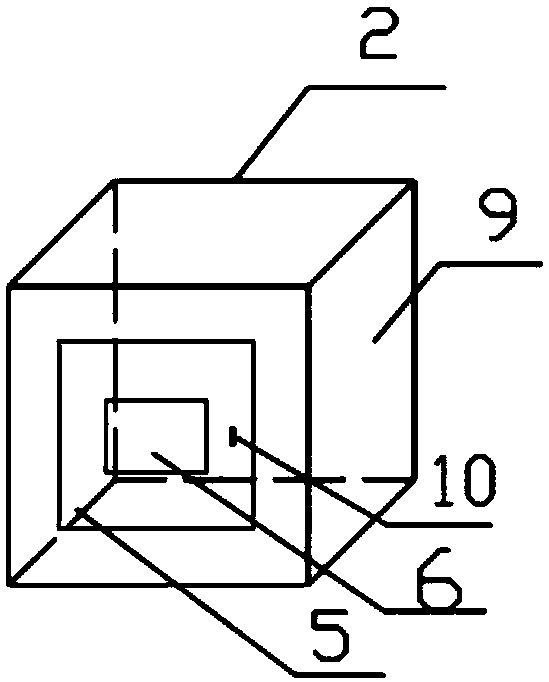

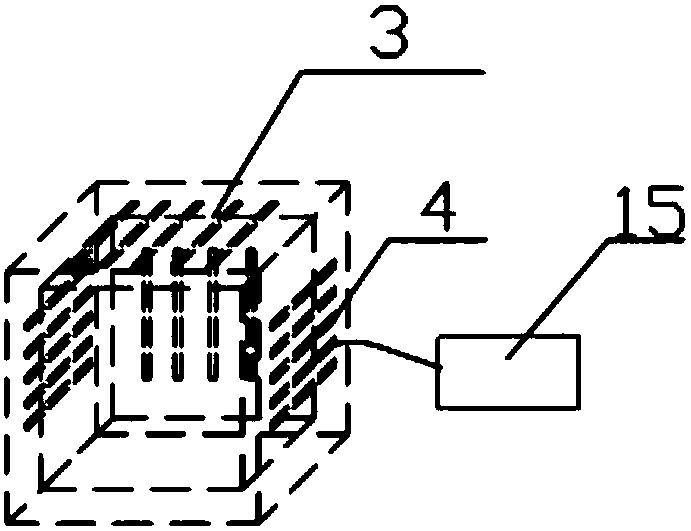

[0040] A test furnace for characterizing the degree of cracking of concrete at high temperature is characterized in that it comprises an electric furnace 1 and a test piece placement device, consisting of figure 1 and image 3 It can be seen that the electric furnace 1 is composed of an outer shell 2, an inner compartment 3 and an electric furnace temperature controller 15, the outer shell 2 is welded by a high-temperature-resistant steel plate 16, and the high-temperature-resistant paint 9 is sprayed on it, and the interval between the inner compartment 3 and the outer shell 2 is adopted Asbestos 8 is used as filling, so that the device is kept warm and insulated. The inner warehouse 3 is built by two layers of refractory bricks 7, and the top surface between the two layers of refractory bricks 7 and the left, right and rear sides Silicon carbide rods 4 are distributed on the top, and the electric furnace temperature controller 15 is movably connected with the outer shell 2. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com