Method for comprehensively recovering copper and sulfur from deep-sea high-sulfur and high-copper ores and application of the method

A technology for recovering copper and high sulfur, applied in solid separation, flotation, etc., can solve the problem that the effective recovery and separation of copper minerals and sulfur minerals cannot be guaranteed, and the pH value of deep-sea high-sulfur and high-copper ores is low, which affects the formation of flotation foam and other problems, to achieve the effect of being suitable for promotion and application, avoiding the interference of seawater ions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

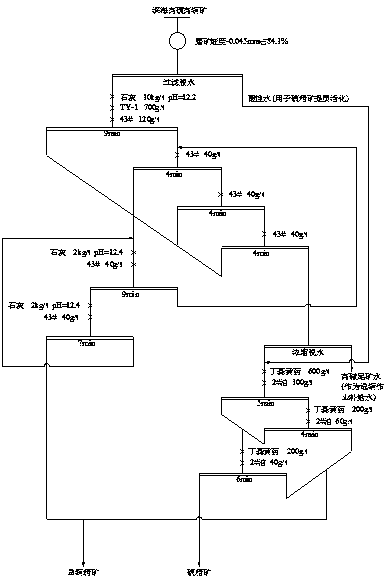

[0029] Embodiment 2: the method for reclaiming copper and sulfur from seabed high-sulfur and high-copper ore, it comprises the following steps: (1), raw ore is ground and filtered dehydration: the raw ore pulp after fully dissociated is carried out filtration dehydration, makes part in The moisture inside the material seeps out after convective diffusion, and the acidic water with pH=4.8 and the copper selection operation feedstock with a concentration of 72% are obtained, in which the acidic water is reserved for the concentrated underflow pulping dilution of the sulfur selection operation; (2), Dilution and roughing of feedstock for copper beneficiation: dilute and stir the 72% feedstock for copper beneficiation with neutral water, adjust the pulp concentration to 28%, add quicklime 10kg / t, and stir for 3 minutes, the measured pH=12.3, Then add TY-1 reagent 700g / t and 43# reagent 120g / t, stir for 2min, and float for 9min to obtain copper roughing foam and copper roughing tail...

Embodiment 3

[0031] Embodiment 3: the method for reclaiming copper and sulfur from seabed high-sulfur and high-copper ore, it comprises the following steps: (1), raw ore is ground and filtered dehydration: the raw ore pulp after fully dissociated is carried out filtration dehydration, makes part in The moisture inside the material seeps out after convective diffusion, and acidic water with pH=5.5 and 75% concentration of copper selection operation feed are obtained, in which the acidic water is reserved for the concentrated underflow pulping dilution of sulfur selection operation; (2), Dilution and roughing of feedstock for copper beneficiation: dilute and stir the 75% copper beneficiation feedstock with neutral water, adjust the slurry concentration to 30%, add quicklime 10kg / t, and stir for 4min, the measured pH=12.2, Then add 700g / t of TY-1 reagent and 120g / t of 43# reagent, stir for 3 minutes, and float for 10 minutes to obtain copper roughing foam and copper roughing tailings; Copper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com