High-throughput non-targeted screening method for pollutants in regenerated PET material for food contact

A food contact and contaminant technology, applied in the direction of material separation, analytical materials, measuring devices, etc., can solve the problem of unrelated standards or methods of recycled PET, systemic risk monitoring and assessment of PET for difficult food contact, non-recycling PET and other problems, to achieve the effects of rapid sensitivity and selectivity, recycling and reuse, strong safety risk assessment, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] Preparation of uniform and stable samples: Take an appropriate amount of recycled PET bottle flakes and grind them in a high-speed rotary grinder, and use them as samples for condition optimization and testing.

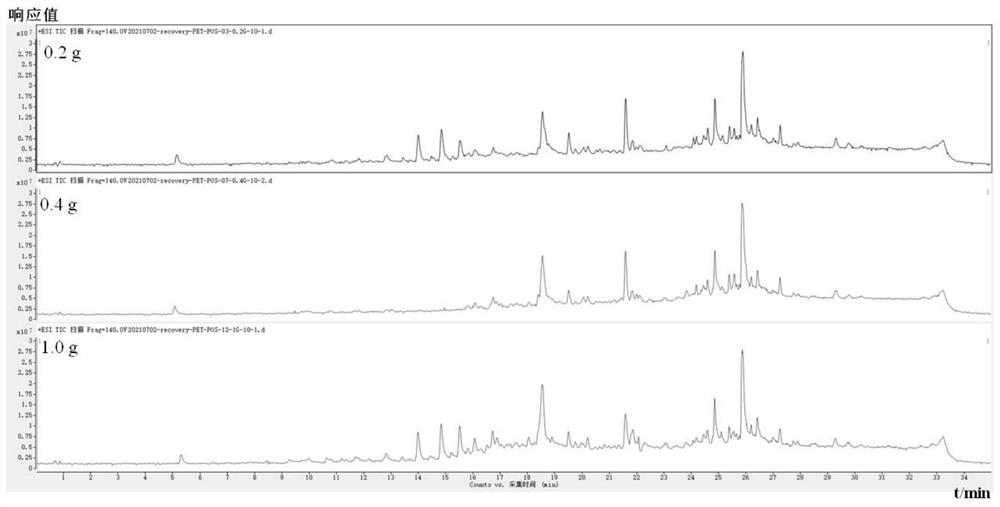

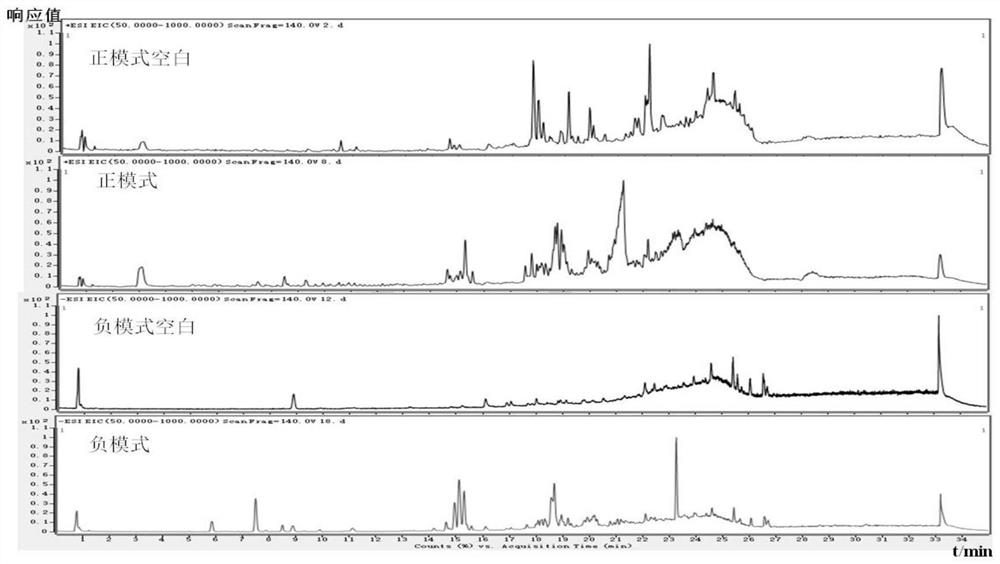

[0035] Weigh 0.2g to 1.0g of the sample to be tested in a clean glass bottle, add an appropriate amount of HFIP to dissolve the polymer, and when it is completely dissolved, add methanol and ultrasonicate for 1 hour to completely precipitate the polymer. Subsequently, the mixture was centrifuged at 9000 rpm for 10 min, the supernatant was taken, the wall of the centrifuge tube and the residual precipitate were washed with 1 mL of methanol, and the obtained supernatants were combined. Blow the supernatant to near dryness under gentle nitrogen flow or rotary evaporation, and redissolve with 1 mL of methanol. The reconstituted solution was filtered through a 0.22 μm filter to obtain the sample to be tested. Two parallels were set up for each sample, and a blank s...

Embodiment 1

[0051] Embodiment 1: the optimization of the method for measuring non-volatile organic pollutants

[0052] 1. Optimization of the pretreatment method

[0053] The sample pretreatment method was optimized by testing the native PET sample spiked recovery rate (50 μL 10 mg / L BBP-D4).

[0054]1.1 Selection of Precipitation Solvent Precipitation solvent is one of the important factors affecting pretreatment efficiency. If precipitation occurs too quickly, it is easy to wrap the substance to be tested; if precipitation occurs slowly or no precipitation occurs, a large amount of solvent will be consumed, which will increase The expenditure also reduces the test efficiency. The experiment investigated the effect of several common solvents (acetone, methanol, n-hexane) on the recovery rate of BBP-D4 spiked. The results are shown in Table 1 below. When methanol was used as the reprecipitation solvent, the recovery rate of the standard addition was the highest. This is because when me...

Embodiment 2

[0076] Embodiment 2: the optimization of the method for measuring volatile organic pollutants

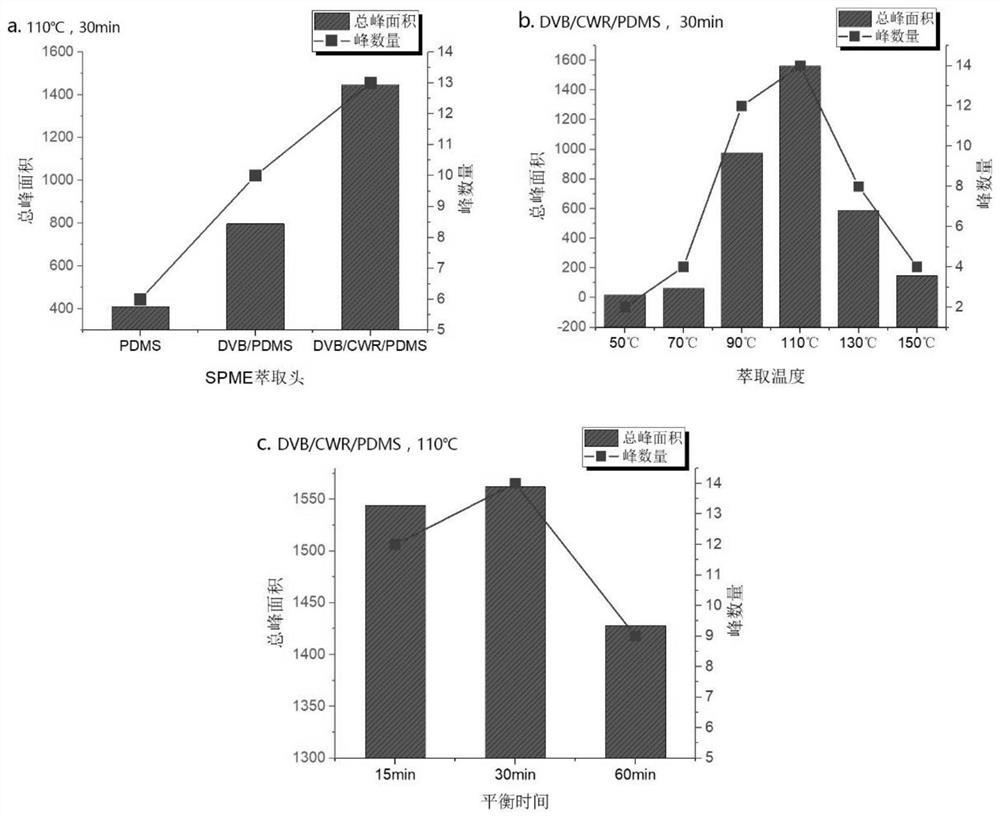

[0077] 2.1 Method optimization

[0078] GC×GC-QTOF-MS was used to optimize the equilibration time, solid phase microextraction temperature, solid phase microextraction fiber head type, oven heating rate and modulation cycle, and the total area of chromatographic peaks and the number of chromatographic peaks were used as the basis for optimization.

[0079] The headspace equilibration time was selected as 15min, 30min and 60min for comparison, the extraction temperature was selected as 50°C, 70°C, 90°C, 110°C, 130°C and 150°C for comparison, and three different types of solid phase microextraction fiber heads were compared ( 100μmPDMS, 65μmDVB / PDMS and 80μmDVB / C-WR / PDMS) extraction effects, in terms of instrument optimization, the separation effects of four heating rates of 3°C / min, 5°C / min, 8°C / min and 10°C / min were compared , and compared the peaking effects of three modulation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com