Method for separating chalcopyrite from marcasite and pyrites in copper and sulphur ores

A separation method and chalcopyrite technology, applied in solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of low separation efficiency and poor separation effect, achieve low dosage, strong guiding significance and reference value, the effect of reducing floatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

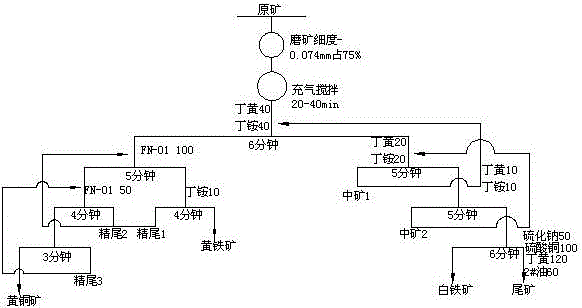

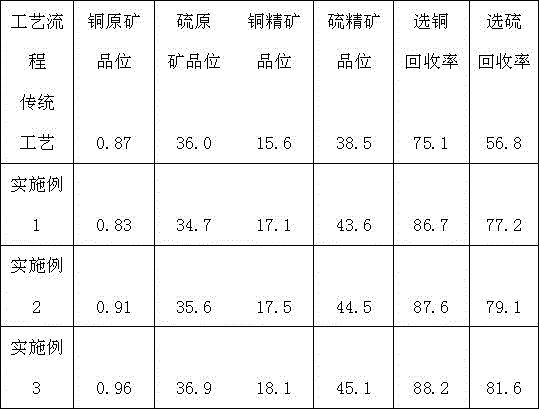

[0013] Example 1: (1), crushing and grinding: the raw ore is crushed and ground to a particle size of -0.074mm, which accounts for 70%; (2) aeration and stirring: the concentration of the ore pulp is adjusted to about 30wt%, put into the mixing tank, and inflated and stirred for 20 minutes, The aeration volume is 3L / min; (3) Rough separation: put the slurry after aeration and stirring into the flotation machine, add 40g / t of butyl xanthate and butyl ammonium black medicine, stir for 2 minutes, and perform aeration and flotation for 4 minutes to obtain Coarse concentrate and roughing tailings; (4) Primary sweeping: Add 20g / t of butyl yellow and butylammonium to the roughing tailings, stir for 2 minutes, and aerate flotation for 3 minutes to get middle ore 1 and first sweep tailings, middle ore 1 Return to roughing; (5) Secondary sweeping: add 10g / t of butyl yellow and butyl ammonium to the tailings of the first sweep, stir for 2 minutes, and float for 3 minutes to get the middle...

Embodiment 2

[0014] Example 2: (1), crushing and grinding: the raw ore is crushed and ground to a particle size of -0.074mm, accounting for 72%; (2) inflated and stirred: the pulp concentration is adjusted to about 33wt% and placed in a mixing tank, and inflated and stirred for 30 minutes. The aeration volume is 5L / min; (3) Rough separation: Put the slurry after aeration and stirring into the flotation machine, add 40g / t of butyl xanthate and butylammonium black medicine, stir for 3 minutes, and perform aeration and flotation for 6 minutes to obtain Coarse concentrate and roughing tailings; (4) Primary sweeping: Add 20g / t of butyl yellow and butylammonium to the roughing tailings, stir for 3 minutes, and aerate flotation for 5 minutes to obtain middle ore 1 and first sweep tailings, middle ore 1 Return to roughing; (5) Second sweeping: Add 10g / t of butyl yellow and butylammonium to the tailings of the first sweep, stir for 3 minutes, and aerate flotation for 5 minutes to obtain the middle o...

Embodiment 3

[0015] Example 3: (1), crushing and grinding: the raw ore is crushed and ground to a particle size of -0.074mm, accounting for 75%; (2) inflated and stirred: the pulp concentration is adjusted to about 35wt% and placed in a mixing tank, and inflated and stirred for 40 minutes. The aeration volume is 7L / min; (3) Rough separation: Put the slurry after aeration and agitation into the flotation machine, add 40g / t of butyl xanthate and butylammonium black medicine, stir for 4 minutes, and perform aeration flotation for 8 minutes to obtain Coarse concentrate and roughing tailings; (4) Primary sweeping: Add 20g / t of butyl yellow and butyl ammonium to the roughing tailings, stir for 4 minutes, and aerate flotation for 7 minutes to obtain middle ore 1 and first sweep tailings, middle ore 1 Return to roughing; (5) Secondary sweeping: add 10g / t of butyl yellow and butyl ammonium to the tailings of the first sweep, stir for 4 minutes, and aerate flotation for 7 minutes to obtain the middle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com