Surface activating agent for oil-field thick-oil well

A surfactant, oil well technology, applied in the directions of drilling composition, dissolution, chemical instruments and methods, etc., can solve the problems of reducing life, reducing crude oil production, affecting pumping unit efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] A kind of surface active agent that oil field dense well is used, is made up of following components:

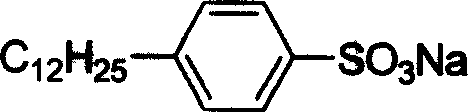

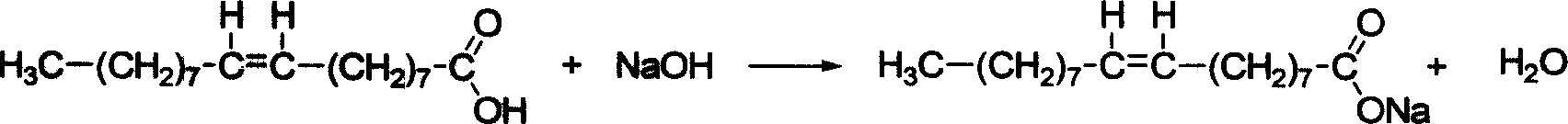

[0017] Water 1500kg, caustic soda NaOH 330kg, ethanol 450kg, oleic acid 275kg, octylphenol polyoxyethylene (15) ether or nonylphenol polyoxyethylene (15) ether 200kg, sodium dodecylbenzenesulfonate 150kg;

[0018] Its preparation method: mix and dissolve water, caustic soda and ethanol, add oleic acid for saponification reaction, react at room temperature, the maximum temperature does not exceed 50 ° C, the pressure is 0.5 MPa, the reaction time is 40 minutes, then stir it, add Octylphenol polyoxyethylene (15) ether or nonylphenol polyoxyethylene (15) ether, then add sodium dodecylbenzene sulfonate and stir, and finally package, 200Kg per plastic drum. How to use: Make it into 0.5-1.5% aqueous solution, inject it into the heavy oil well, let it suffocate for 14 hours, and then start the oil extraction machine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com