Physical simulation huff-puff production experimental method and device

A technology of physical simulation and experimental method, applied in the fields of fluid production, earthwork drilling, wellbore/well components, etc., can solve the problems of time-consuming, labor-intensive operation, inconvenience, etc., and achieve flexible and convenient operation, easy injection, and easy operation. The effect of mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

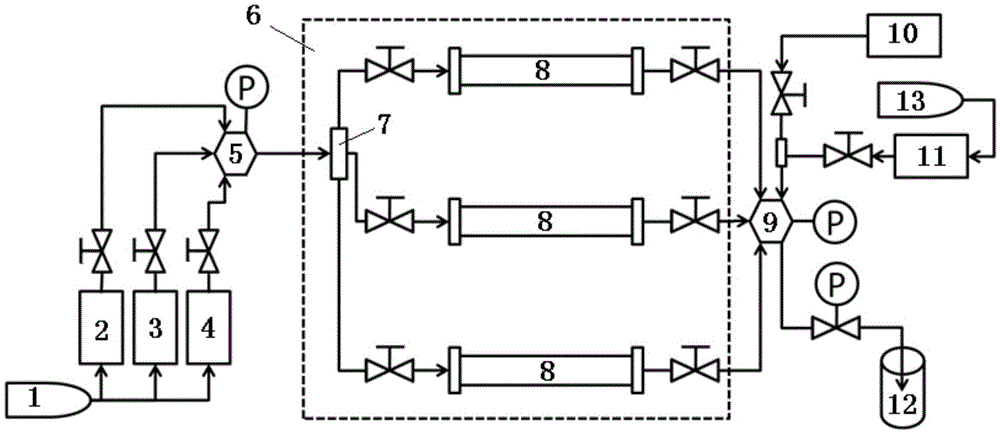

[0041] like figure 1 As shown, the experimental device of the present embodiment includes a booster pump 1, and the output end of the booster pump 1 communicates with the inlets of a water intermediate container 2, an oil intermediate container 3 and a gas intermediate container 4 through pipelines respectively, and the water The outlets of the intermediate container 2, the oil intermediate container 3 and the gas intermediate container 4 communicate with a six-way valve 5 through pipelines respectively. The six-way valve 5 communicates with a four-way valve 7 arranged in the thermostat 6 through a pipeline, and the four-way valve 7 communicates with the inlets of three rock core models 8 arranged in the thermostat 6 respectively through three pipelines. The outlets of each rock core model 8 communicate with the same six-way valve 9 through pipelines respectively. The six-way valve 9 communicates with a steam generator 10, a chemical intermediate container 11 and a receiver 1...

Embodiment 2

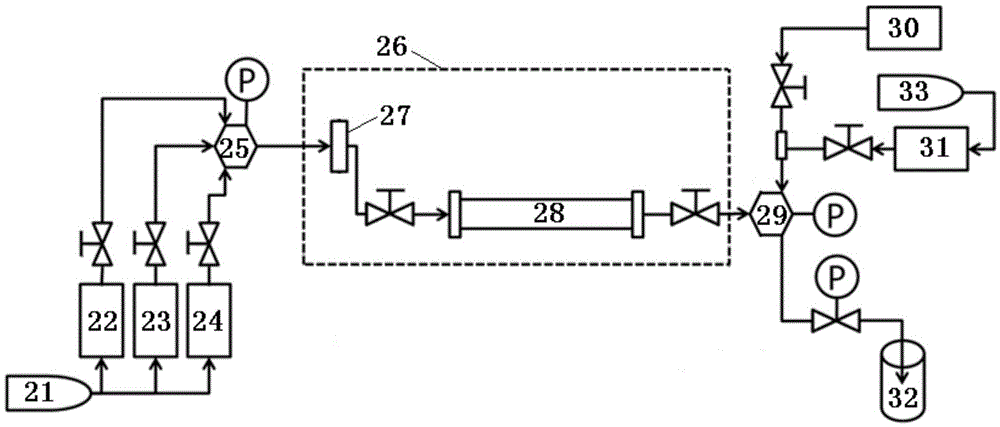

[0049] like figure 2 As shown, the experimental device of the present embodiment comprises a booster pump 21, and the output end of the booster pump 21 communicates with the inlets of a water intermediate container 22, an oil intermediate container 23 and a gas intermediate container 24 respectively through pipelines, and the water The outlets of the intermediate container 22 , the oil intermediate container 23 and the gas intermediate container 24 communicate with a six-way valve 25 through pipelines respectively. The six-way valve 25 communicates with a four-way valve 27 arranged in the thermostat 26 through a pipeline, and the four-way valve 27 communicates with the inlet of a rock core model 28 arranged in the thermostat 26 through the pipeline, and the core model 28 The outlet communicates with a six-way valve 29 through a pipeline. The six-way valve 29 communicates with a steam generator 30, a chemical intermediate container 31 and a receiver 32 respectively through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com