Ceramic brick prepared from aeolian sand

A technology of ceramic tiles and aeolian sand, which is applied in the field of ceramic tiles to achieve the effects of low water absorption, high fineness and quality, and improved process performance

Inactive Publication Date: 2011-10-12

马东升

View PDF3 Cites 16 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] At present, domestic aeolian sand is mostly used for filling roadbeds, but it has not been applied to the production of ceramic brick bodies.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

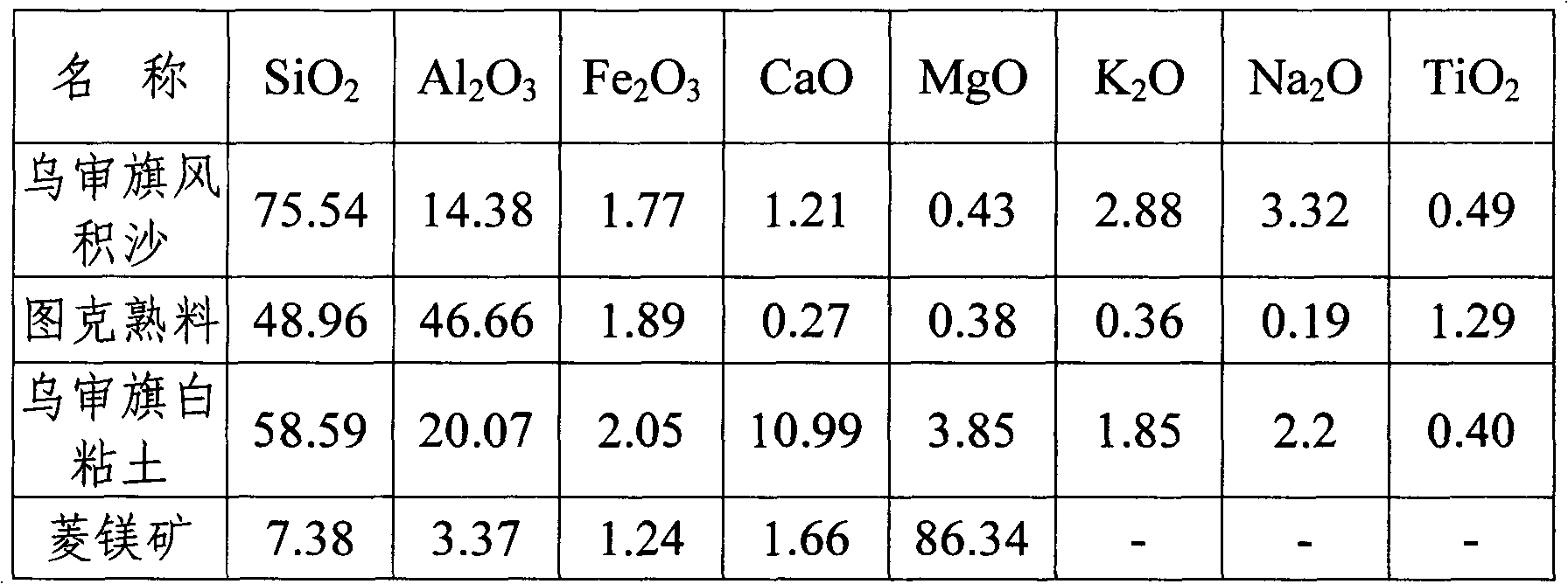

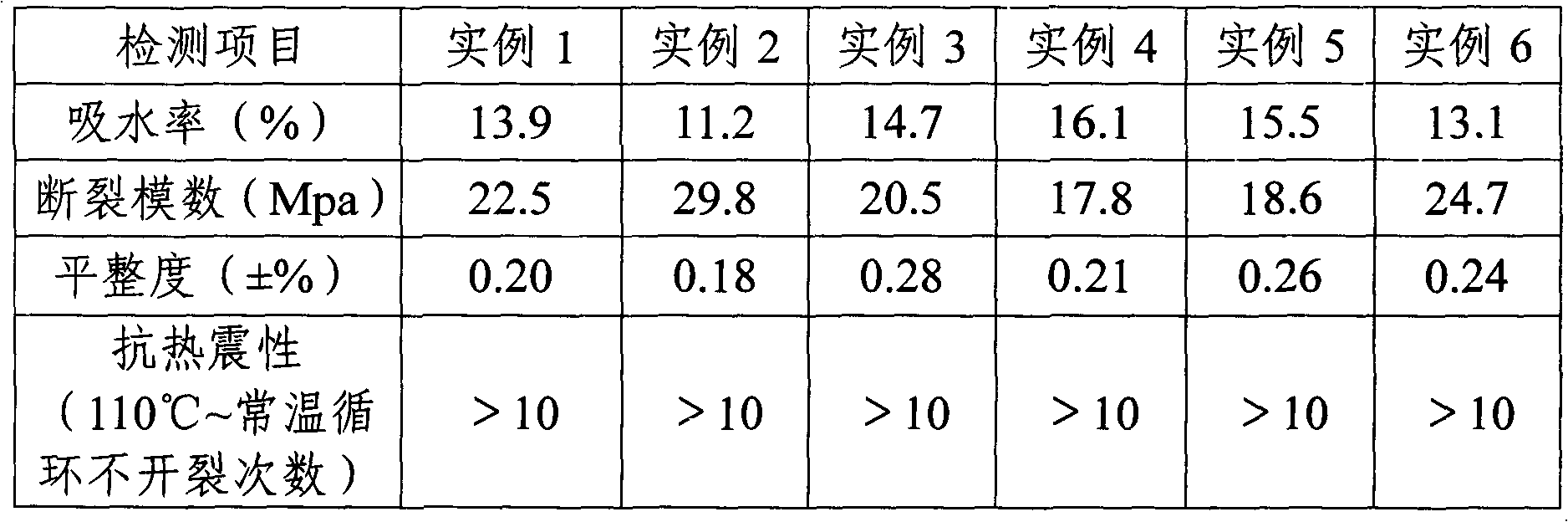

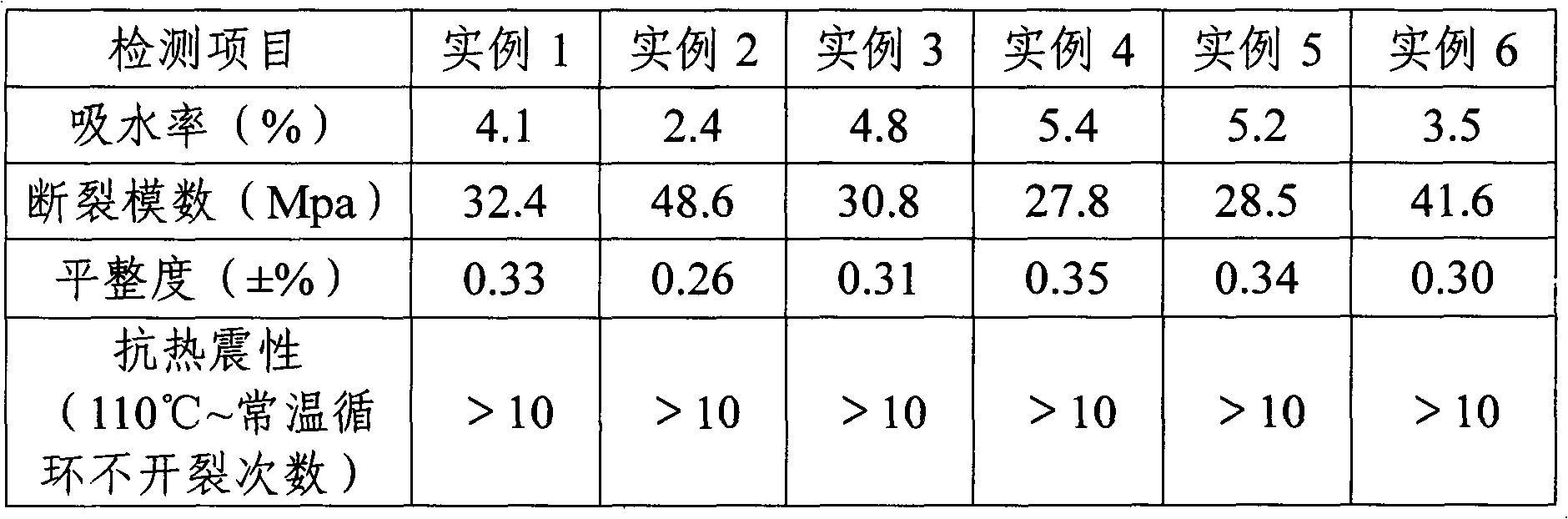

[0016] Embodiments 1-6, with the raw materials of the chemical composition described in Table 1, carry out batching according to the composition shown in Table 2.

[0017] Table 2 Unit: wt%

[0018]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a ceramic brick prepared from aeolian sand. The ceramic brick comprises the following raw materials by weight percent: 50-60% of Uxen aeolian sand. 20-28% of Tuke clinker, 12-20% of Uxen white clay and 2-8% of magnesite. The ceramic product is prepared by the steps of ball milling, smashing, sieving, deironing, forming and firing at the temperature of 1080-1220 DGE C. According to the invention, the aeolian sand enriched in Inner Mongolia is used as a main ceramic-making material, which is beneficial to low-cost desert control and leads the production cost of the ceramic product to be greatly reduced; and the prepared ceramic product has the advantages of excellent quality, small size difference, low water absorption and high strength, and relative indexes reach the requirement of national detection standards.

Description

technical field [0001] The invention belongs to the field of inorganic non-metallic materials (ceramics), and in particular relates to a ceramic brick prepared by utilizing aeolian sand. Background technique [0002] Aeolian sand is sandy soil formed on the surface after natural wind transportation, grading, and deposition. Its particles are uniform, fine, and its composition is stable. Quartz is the main mineral mixed with feldspar and mica. [0003] In Wushen Banner, Ordos, Inner Mongolia, the distribution area of aeolian sand is about 2821 square kilometers. The geological report of detailed investigation of aeolian sand and related data show that the content of mineral components of aeolian sand distributed in this area does not change much, and the bulk mineral components The content is stable, and it can be used as a raw material base for large-scale industrial development. [0004] The main component of aeolian sand in Wushen Banner is SiO 2 and Al 2 o 3 , and c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B33/13

Inventor 马东升

Owner 马东升

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com