Preparation method and product of multiple lactic acid bacteria fermentation agent for fermented milk

A fermented milk and lactic acid bacteria fermentation technology, applied in the field of food industry, can solve the problems of homogenization and low-price competition, and achieve the effect of stable product performance and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 3

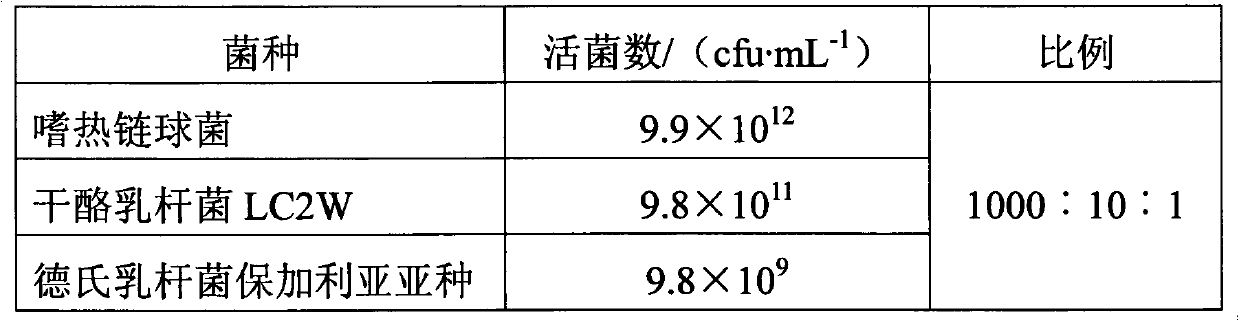

[0035] Embodiment 1 triple lactic acid bacteria starter

[0036] Bacteria composition and culture conditions:

[0037] bacteria

culture medium

Streptococcus thermophilus

M17 / skimmed milk

[0038] Lactobacillus delbrueckii subsp. bulgaricus

MRS / skim milk

Lactobacillus casei LC2W

MRS / skim milk

[0039] The preparation method comprises the following steps:

[0040] 1) Inoculate the Streptococcus thermophilus stored on the slant into 100 mL of M17 medium, and the M17 medium containing the Streptococcus thermophilus (Streptococcus thermophilus) strain obtained after anaerobic cultivation at 45°C for 6 hours was mixed with 1% (v / v) The amount of inoculum was inoculated in 8L of aqueous solution containing 12% (wt) sterilized skim milk powder, and the first expansion was carried out at a culture temperature of 45°C and a culture time of 10h; Oxygen fermentation, pH constant at 6.2;

[0041] 2) Inoculate the liquid obta...

Embodiment 2 4

[0056] Embodiment 2 quadruple lactic acid bacteria starter

[0057] Bacteria composition and culture conditions:

[0058] bacteria

culture medium

M17 / skimmed milk

Lactobacillus delbrueckii subsp. bulgaricus

MRS / skim milk

MRS / skim milk

Lactobacillus casei BD-II

MRS / skim milk

[0059] The preparation method comprises the following steps:

[0060] 1) Inoculate the Streptococcus thermophilus stored on the slant into 100 mL of M17 medium, and the M17 medium containing the Streptococcus thermophilus (Streptococcus thermophilus) strain obtained after anaerobic cultivation at 45°C for 6 hours was mixed with 1% (v / v) The amount of inoculum was inoculated in 2L of aqueous solution containing 12% (wt) sterilized skim milk powder, and the first expansion was carried out at a culture temperature of 42°C and a culture time of 12 hours; Oxygen fermentation, pH constant at 6....

Embodiment 3 5

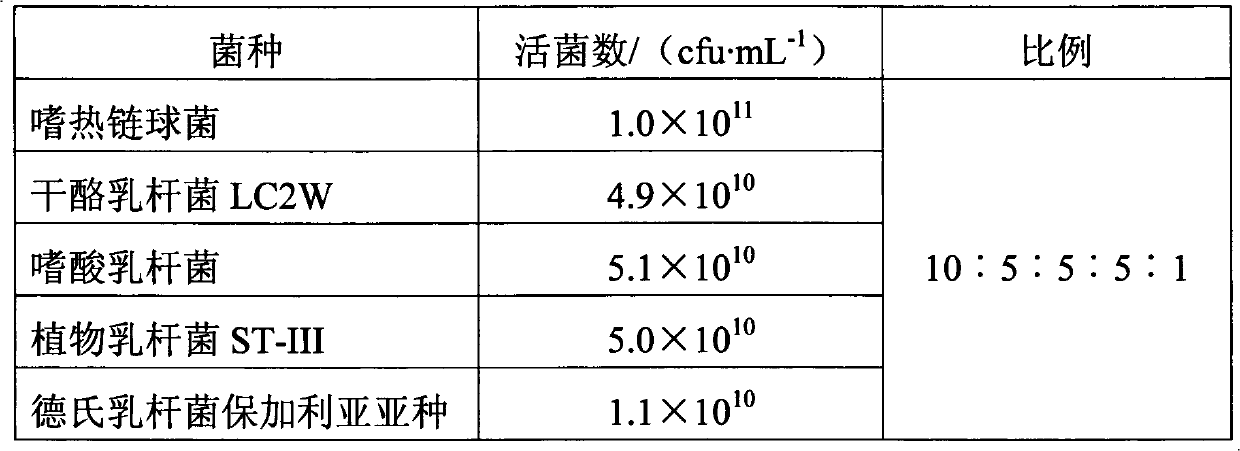

[0079] Embodiment 3 five-linked lactic acid bacteria starter

[0080] Bacteria composition and culture conditions:

[0081] bacteria

culture medium

Streptococcus thermophilus

M17 / skimmed milk

Lactobacillus delbrueckii subsp. bulgaricus

MRS / skim milk

[0082] Lactobacillus casei LC2W

MRS / skim milk

MRS / skim milk

Lactobacillus plantarum ST-III

MRS

[0083] The preparation method comprises the following steps:

[0084] 1) Inoculate the Streptococcus thermophilus stored on the slant into 100 mL of M17 medium, and the M17 medium containing the Streptococcus thermophilus (Streptococcus thermophilus) strain obtained after anaerobic cultivation at 45°C for 6 hours was mixed with 1% (v / v) The amount of inoculum was inoculated in 4L of aqueous solution containing 12% (wt) sterilized skim milk powder, and the first expansion was carried out at a culture temperature of 45°C and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com