Durable alkali-free liquid setting accelerator and preparation method thereof

A technology of quick-setting agent and durability, which is applied in the field of alkali-free liquid quick-setting agent and its preparation, and can solve problems such as adverse effects on concrete durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

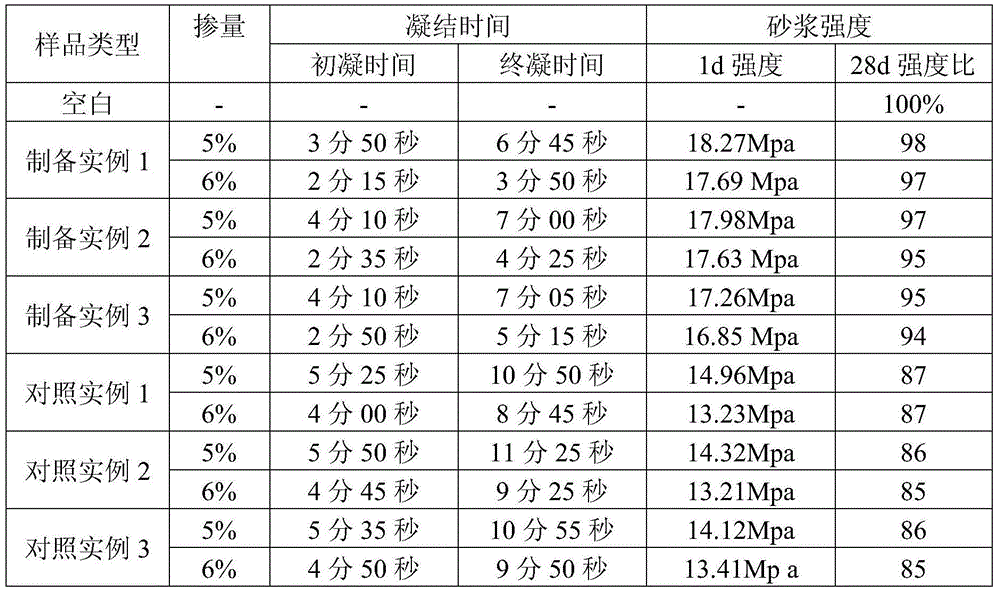

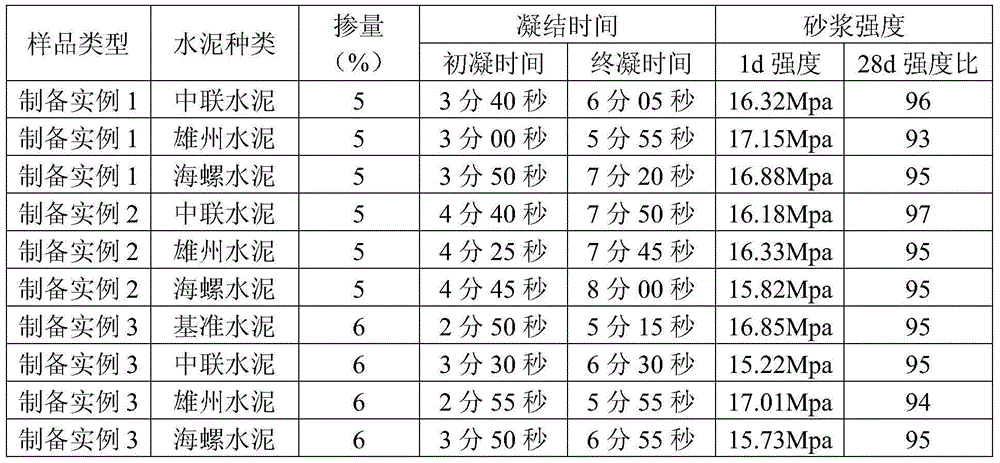

Examples

Embodiment 1

[0027] (1) Preparation of modified aluminum hydroxide sol

[0028] Add 700 g of 15 mol / L concentrated ammonia water dropwise to 300 g of amorphous aluminum hydroxide with an alumina content of 63.5%, dropwise for 35 minutes, and keep the temperature in a water bath at 80°C until the aluminum hydroxide precipitates and disperses to obtain a stable transparent aluminum hydroxide sol.

[0029] (2) Preparation of modified silica sol

[0030] Mix 2g of silica sol with a silica content of 27% and 40g of 12 C silane coupling agent in 158g of aqueous solution, stir in a constant temperature water bath at 60°C for 2 hours, and prepare a modified silica sol solution;

[0031] (3) Preparation of modified alcohol amine

[0032] With 100g triethanolamine and 50.3g glycolic acid (the molar ratio of triethanolamine and glycolic acid is 1:1)

[0033] React in a constant temperature water bath at 75°C for 3 hours, and cool to obtain a modified alcoholamine.

[0034] (4) Add the following co...

preparation Embodiment 2

[0042] (1) Preparation of modified aluminum hydroxide sol

[0043] Add 800 g of 18 mol / L concentrated ammonia water dropwise to 200 g of amorphous aluminum hydroxide with an alumina content of 65%, for a period of 45 minutes, and keep the temperature in a water bath at 85°C until the aluminum hydroxide precipitates and disperses to obtain a stable transparent aluminum hydroxide sol.

[0044] (2) Preparation of modified silica sol

[0045] Mix 4g of silica sol with a silica content of 28% and 80g of 12 C silane coupling agent in 116g of aqueous solution, stir in a constant temperature water bath at 55°C for 2 hours, and prepare a modified silica sol solution;

[0046] (3) Preparation of modified alcohol amine

[0047] With 50g triethanolamine and 50.3g glycolic acid (the molar ratio of triethanolamine and glycolic acid is 1:2) in

[0048] React in a constant temperature water bath at 80°C for 2.5 hours, and cool to obtain the modified alcoholamine.

[0049] (4) Add the follo...

preparation Embodiment 3

[0057] (1) Preparation of modified aluminum hydroxide sol

[0058] In 100g of amorphous aluminum hydroxide with an alumina content of 60%, 900g of 20mol / L concentrated ammonia water was added dropwise for 60 minutes, and the temperature was kept constant in a water bath of 85°C until the aluminum hydroxide was precipitated and dispersed to obtain a stable transparent aluminum hydroxide sol.

[0059] (2) Preparation of modified silica sol

[0060] Mix 6g of silica sol with a silica content of 27% and 120g of 18C silane coupling agent in 74g of aqueous solution, stir in a constant temperature water bath at 60°C for 3 hours, and prepare a modified silica sol solution;

[0061] (3) Preparation of modified alcohol amine

[0062] 50g triethanolamine and 75.5g glycolic acid (the molar ratio of triethanolamine and glycolic acid is 1:3) in

[0063] React in a constant temperature water bath at 75°C for 3 hours, and cool to obtain the modified alkanolamine.

[0064] (4) Add the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com