Clean and simple preparation method of tin oxide surface modified lithium manganite and modified lithium manganite positive electrode material prepared by clean and simple preparation method

A technology of lithium manganate and cathode material, applied in the field of modified lithium manganate cathode material, can solve the problems of difficult large-scale industrialization, high energy consumption, complex process, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

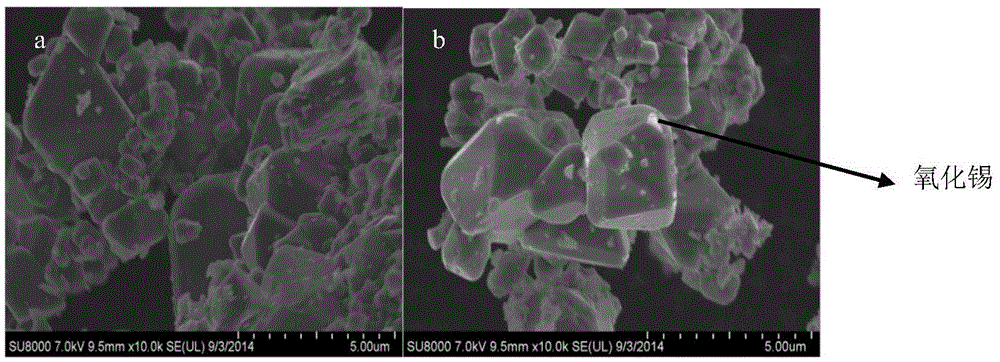

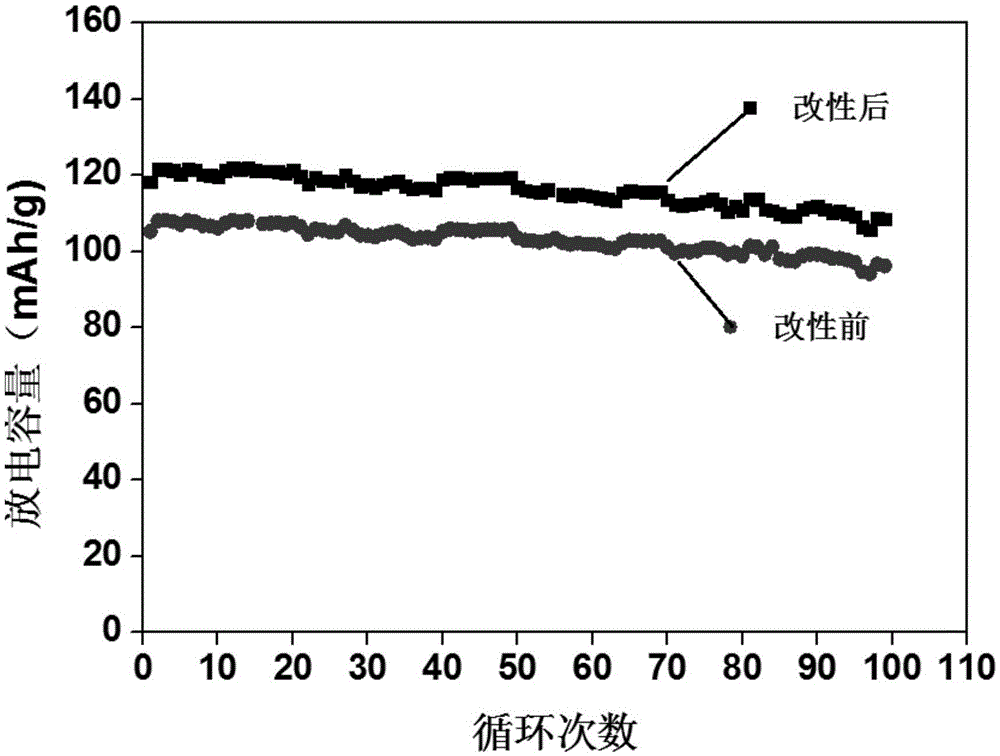

[0025] Dissolve 0.2283 g of stannous chloride in 150 mL of deionized water, disperse by ultrasonic for 30 minutes, add 7.9930 g of lithium manganate with a particle size of 5 μm after uniform dispersion, stir vigorously for 8 hours, filter and dry to obtain surface-modified manganese Lithium oxide material. The drying is completed in an oven, the baking temperature is 100°C, and the baking time is 360 minutes.

Embodiment 2

[0027] Dissolve 0.2283 g of stannous chloride in 150 mL of ethanol, ultrasonically disperse for 30 minutes, add 7.9930 g of lithium manganate after uniform dispersion, stir vigorously for 8 hours, filter and dry to obtain surface-modified lithium manganate Material. The drying is completed in an oven, the baking temperature is 120° C., and the baking time is 320 minutes.

Embodiment 3

[0029] Dissolve 0.2283 g of stannous chloride in 150 mL of acetic acid, ultrasonically disperse for 30 minutes, add 7.9930 g of lithium manganate after uniform dispersion, stir vigorously for 8 hours, filter and dry to obtain surface-modified lithium manganate Material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com