Compound material support roller and preparation method thereof

A technology of composite materials and rollers, which is applied in the direction of rollers, conveyor objects, transportation and packaging, etc., can solve the problems of high friction coefficient, low impact resistance, high manufacturing cost, etc., and achieve excellent impact resistance and low production cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The first step: weighing and drying

[0023] Weigh 85kg of ultra-high molecular polyethylene particles, place in an oven and heat to 120°C, dry for 60 minutes to remove water and take out;

[0024] The second step: add accessories, mix and stir

[0025] Take 0.5kg of titanate as coupling agent, 0.1kg of copper powder as antistatic agent, 0.1kg of microencapsulated red phosphorus and 0.2kg of decabromodiphenyl ether as flame retardant, and 0.1kg of polyethylene wax stearic acid as fluid Modifier and 0.5kg of nano-calcium carbonate, mixed with dried ultra-high molecular polyethylene.

[0026] The third step: extruder extrusion, cooling

[0027] The mixture was added to an extruder that had been heated at 110°C, 160°C, 220°C, 240°C and 220°C for extrusion to form a cylinder, and put into a water tank to cool.

[0028] Step 4: Machining and Assembly

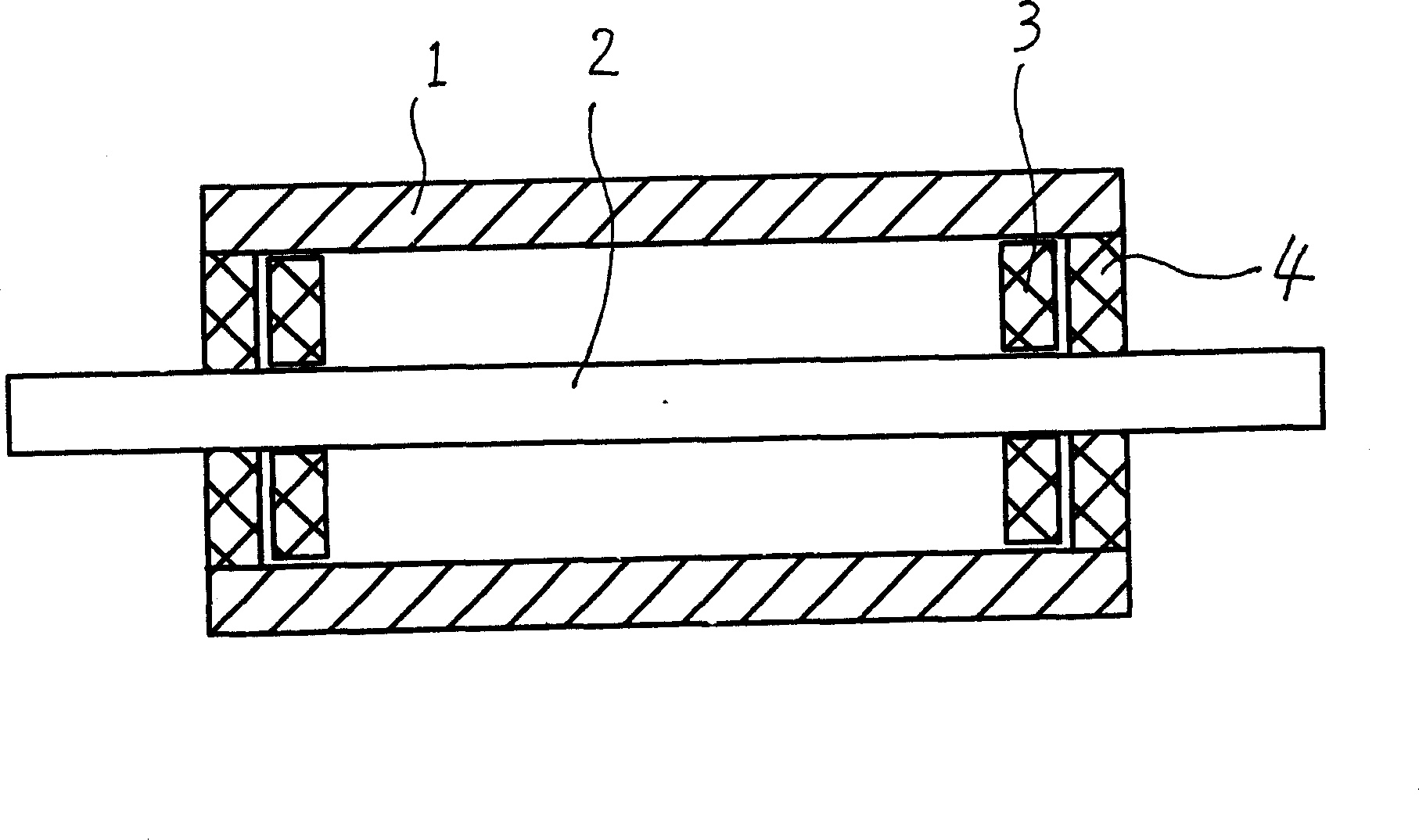

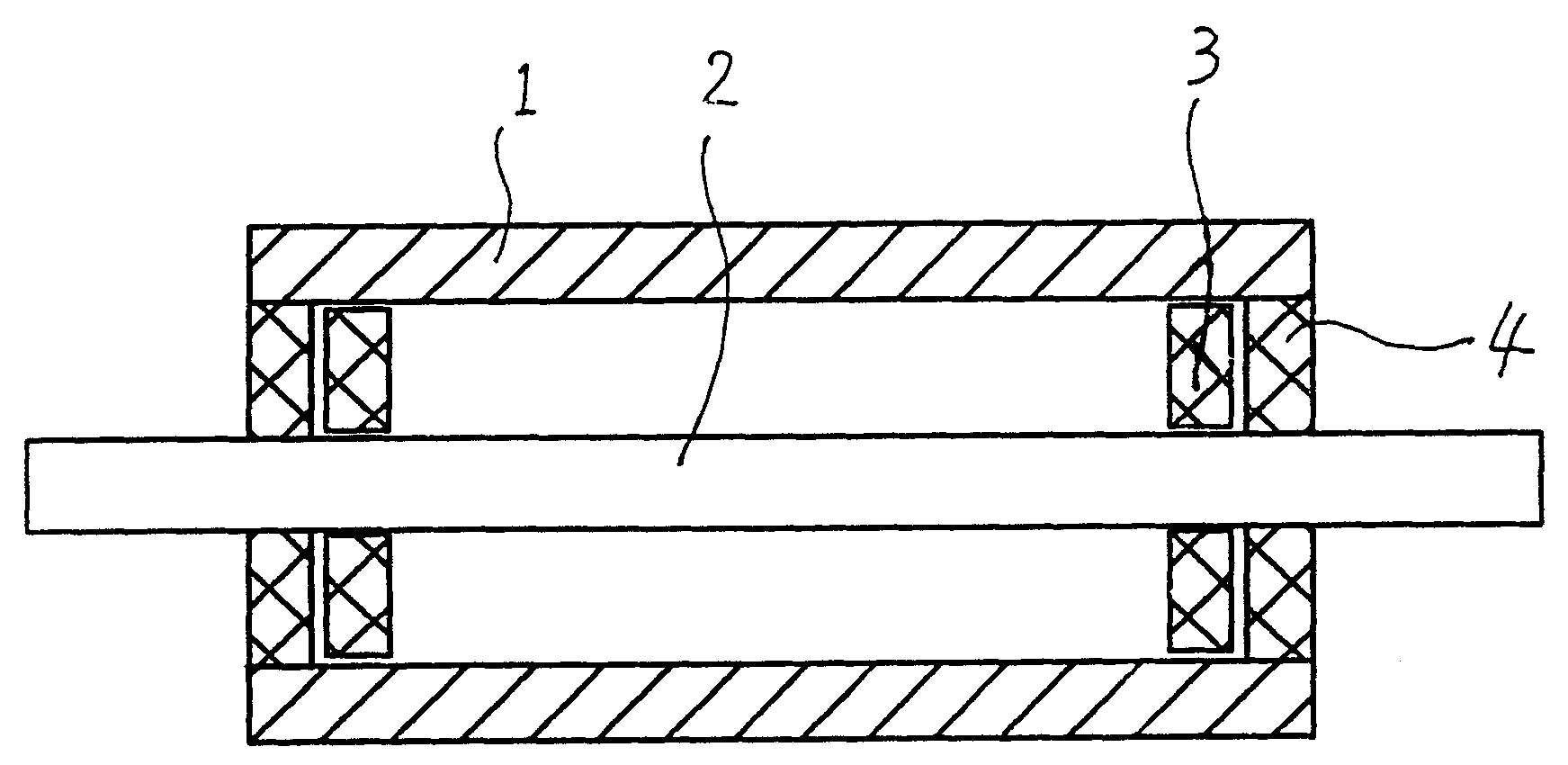

[0029] Cut the cooled cylinder into roller cylinder 1 according to the design, put the rotating shaft 2 fixed with the b...

Embodiment 2

[0032] The first step: weighing and drying

[0033] Weigh 90kg of ultra-high molecular weight polyethylene particles, place in an oven and heat to 125°C, dry for 55 minutes to remove water and take out;

[0034] The second step: add accessories, mix and stir

[0035] After taking 0.6kg of vinyl siloxane as coupling agent, 0.1kg of graphite as antistatic agent and 1.0kg of nano glass beads, mix them with dried ultra-high molecular polyethylene and mix them with dried ultra-high molecular weight polyethylene. Molecular polyethylene is mixed and stirred.

[0036] The third step: extruder extrusion, cooling

[0037] Put the mixture into an extruder that has been heated to 100°C, 150°C, 200°C, 230°C, 210°C to form a cylinder and put it into a water tank to cool.

[0038] Step 4: Machining and Assembly

[0039] Cut the cooled cylinder into roller cylinder 1 according to the design, put the rotating shaft 2 fixed with the bearing 3 into it, and put the sealing blocks 4 at both en...

Embodiment 3

[0041] The first step: weighing and drying

[0042] Weigh 95kg of ultra-high molecular weight polyethylene particles, place in an oven and heat to 120°C, dry for 65 minutes to remove water and take out;

[0043] The second step: add accessories, mix and stir

[0044] Take 1.0kg of acrylic siloxane as coupling agent, 0.5kg of polyethylene wax stearic acid as flow modifier and 1.5kg of nano wollastonite, mix and stir with dried ultra-high molecular weight polyethylene

[0045] The third step: extruder extrusion, cooling

[0046] Put the mixture into an extruder that has been heated to 120°C, 170°C, 230°C, 240°C, 210°C to form a cylinder and put it into a water tank to cool.

[0047] Step 4: Machining and Assembly

[0048] Cut the cooled cylinder into roller cylinder 1 according to the design, put the rotating shaft 2 fixed with the bearing 3 into it, and put the sealing blocks 4 at both ends of the cylinder, and then form a roller cylinder that can be used in salt fields, gra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com