Loop pin

A ring pin and head technology, applied in the field of high-strength ring pins, can solve problems such as the inability to obtain specified strength, and achieve the effects of a good environment, improved production efficiency, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

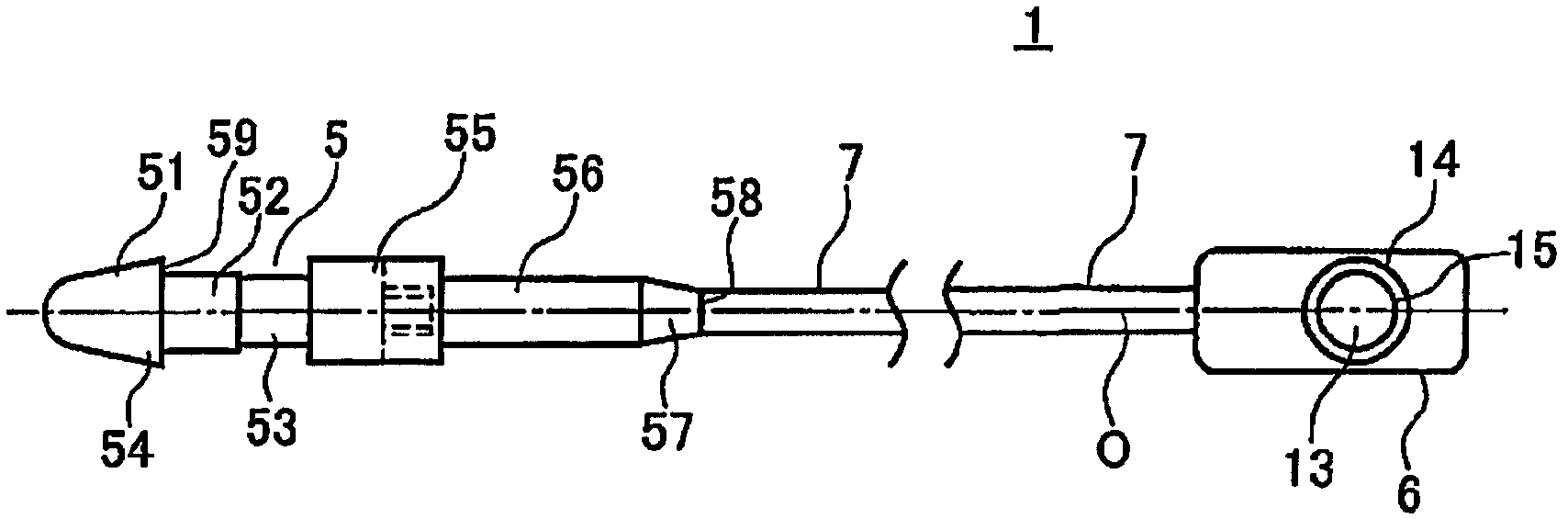

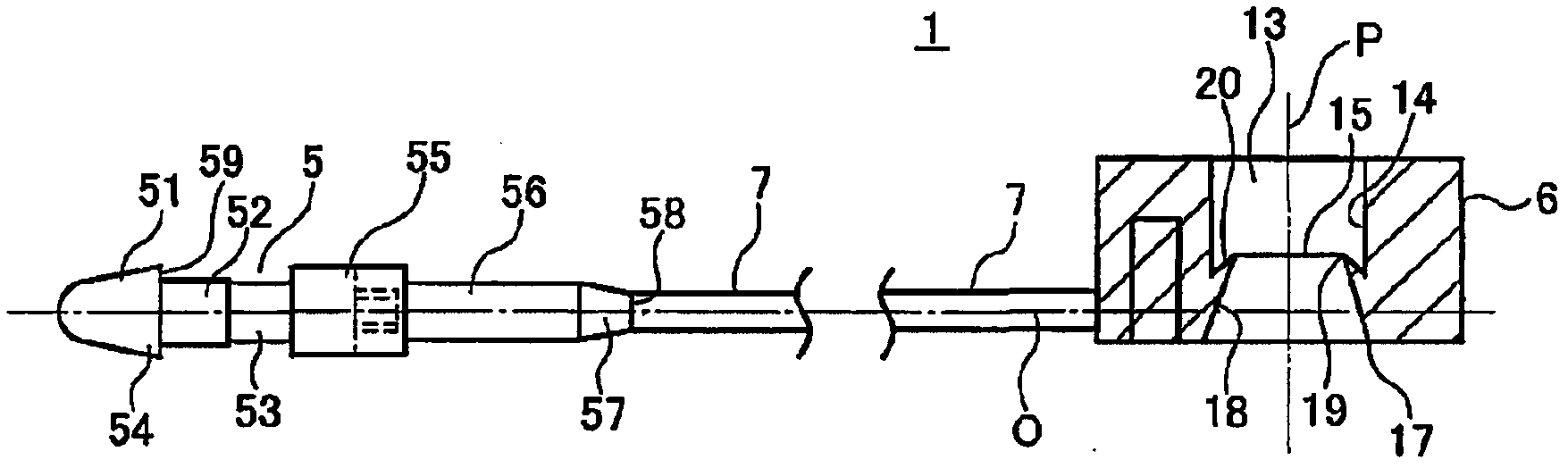

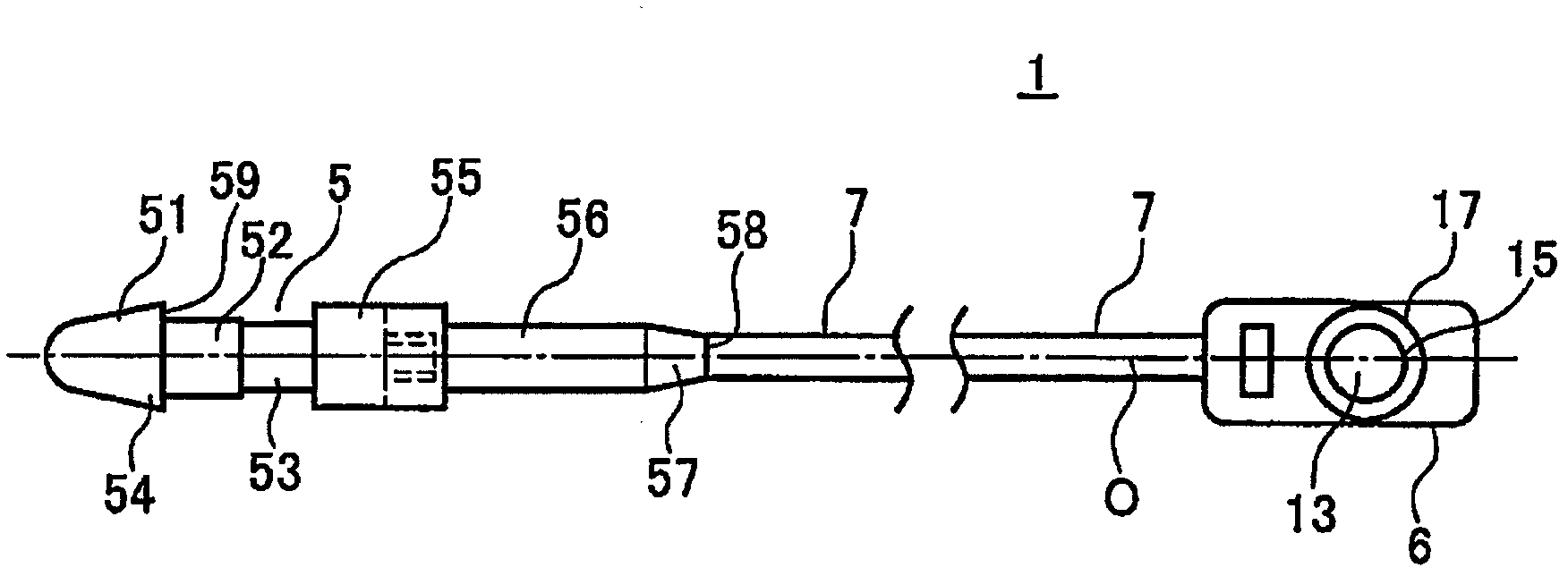

[0051] Next, specific examples of the ring pin 1 of the present invention will be described. That is, using commercially available polypropylene resin integral molding processing has Figures 1 to 4 Ring pins of the construction shown. The length of the head portion 51 of the insertion head portion 5 is 2 mm, and the length of the maximum diameter portion of the lower end portion 54 of the head portion 51 is 1.76 (preferably 1.75-1.85 mm); The length of 52 is 1.3mm (preferably 1.20-1.35mm), and its diameter is 1.29mm (preferably 1.20-1.35mm); meanwhile, the length of the second narrow portion 53 is 1.0mm (preferably 0.8-1.3mm) ) with a diameter of 1.18 mm (preferably 1.15 to 1.25 mm). In addition, the thickness of the fiber portion is 1.17 mm (preferably 0.70 to 1.18 mm).

[0052] Also, in the figure, 55 is an enlarged diameter portion connected to the end of the second narrow diameter portion 53 ; 56 is an unextended portion connected to the enlarged diameter portion 55 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com